3 Major Applications of Helical Gears in Renewable Energy Systems

Author Sushmita Das on August 6, 2024

Renewable energy systems are playing a crucial role in the global transition toward sustainable and environmentally friendly power generation. Among the various components that ensure the efficiency and reliability of these systems, helical gears hold a significant place. Known for their precision and durability, helical gears are integral in numerous renewable energy applications, from wind turbines to solar tracking systems.

In this article, you shall explore the importance of helical gears in renewable energy systems, exploring their design, functionality, and contributions to the sector.

Continue reading…

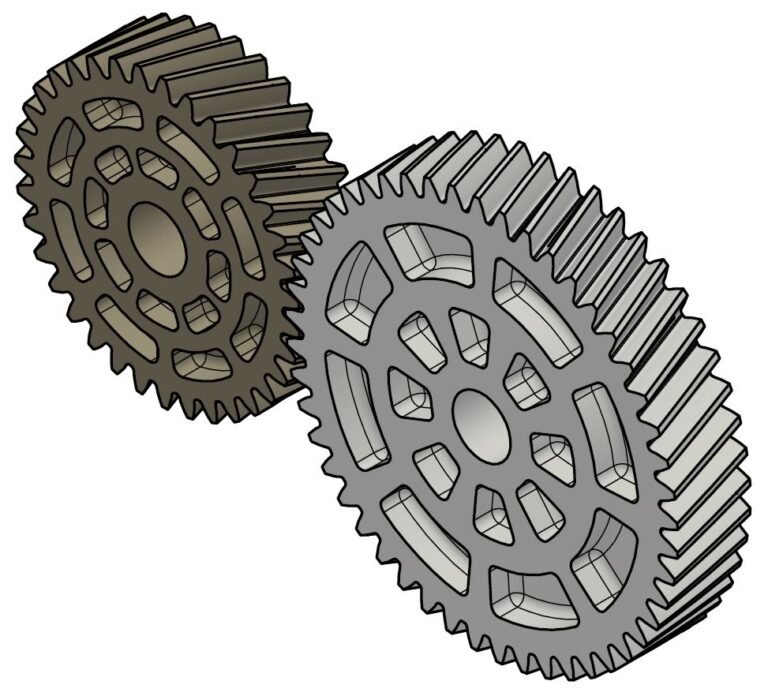

Picture Courtesy – igus GmbH

Basics of Helical Gears

Helical gears are a type of cylindrical gear with teeth that are cut at an angle to the gear’s axis. Such a design forms a helix shape, hence the name ‘helical gears.’ The angled teeth engage more gradually compared to spur gears, resulting in smoother and quieter operation. This gradual engagement also allows for the transmission of higher loads and reduced wear and tear on the gears, making them suitable for high-stress applications.

Key features of helical gears include:

- Smooth and Quiet Operation: The angled teeth reduce noise and vibration, which is quintessential in applications where noise reduction is critical.

- High Load Capacity: The helical design allows for better load distribution across the gear teeth, increasing their capacity to handle heavy loads.

- Efficiency: Helical gears operate with higher efficiency compared to other types of gears, which is crucial for maintaining the overall efficiency of renewable energy systems.

Role of Helical Gears in Wind Turbines

Wind turbines are one of the most prominent applications of renewable energy. They convert kinetic energy from wind into electrical energy for further distribution of power. The gearbox within a wind turbine is a critical component, and helical gears are generally used within these gearboxes due to their ability to handle higher loads and provide reliable, efficient performance.

Gearbox Configuration:

- High-Speed Shaft: Connected to the generator, it requires gears that can handle high rotational speeds without excessive noise or wear. Helical gears are ideal for this purpose.

- Intermediate and Low-Speed Shafts: These shafts require gears that can manage varying loads and speeds efficiently. The smooth operation of helical gears ensures that energy loss is minimized and the gearbox remains durable over long periods.

Advantages of Helical Gears in Wind Turbines:

- Durability and Longevity: Helical gears’ ability to distribute loads evenly reduces stress on individual teeth, prolonging the life of the gearbox.

- Noise Reduction: Wind turbines often operate in populated areas where noise can be a concern. The quiet operation of helical gears helps in minimising noise pollution.

- Efficiency: As wind turbines need to convert as much wind energy into electrical energy as possible, the high efficiency of helical gears contributes to the overall efficiency of the turbine.

Helical Gears in Solar Tracking Systems

Solar tracking systems are designed to optimise the orientation of solar panels to maximise energy captured from the sun. These systems use gears to adjust the positioning of the panels throughout the day. Helical gears are particularly advantageous in solar tracking systems for various reasons.

Precision and Smooth Motion:

- Accurate Tracking: The precision of helical gears ensures that solar panels are accurately aligned with the sun’s position, maximising energy absorption.

- Smooth Operation: The gradual engagement of helical gears allows for smooth adjustments, which is crucial for maintaining the alignment without causing mechanical stress.

Load Management:

- Handling Variable Loads: Solar panels face varying loads due to wind and other environmental factors. Helical gears can efficiently manage these changing loads, ensuring consistent performance.

- Durability in Harsh Conditions: The robust nature of helical gears allows them to operate effectively even in harsh outdoor environments, contributing to the reliability of solar tracking systems.

Helical Gears in Hydroelectric Power Systems

Hydroelectric power systems generate electricity by harnessing the energy of flowing or falling water. Helical gears are used in these systems to transmit power from the turbines to the generators.

Efficiency and Reliability:

- High Efficiency: Helical gears ensure that the maximum amount of energy is transferred from the turbine to the generator with minimal losses, enhancing the overall efficiency of the hydroelectric power plant.

- Durability: The constant operation and high loads in hydroelectric systems require gears that can withstand continuous use. Helical gears are known for their durability and ability to handle such conditions.

Advantages in Hydroelectric Systems:

- Smooth Power Transmission: The smooth operation of helical gears ensures consistent and reliable power transmission, which is critical for the stability of the electricity supply.

- Low Maintenance: Due to their robust design, helical gears require less frequent maintenance, reducing downtime and operational costs.

Future Prospects and Innovations

As renewable energy technology continues to advance, the role of helical gears is expected to expand further. Innovations in materials and manufacturing processes are likely to enhance the performance and durability of helical gears. Additionally, the integration of smart technology and real-time monitoring can optimize the operation and maintenance of helical gears in renewable energy systems.

Material Innovations:

- Advanced Composites: The use of advanced composite materials can reduce the weight of helical gears while maintaining or even improving their strength and durability.

- Coatings and Treatments: Innovative coatings and surface treatments can further enhance the wear resistance and longevity of helical gears.

Smart Technology:

- Condition Monitoring: Implementing sensors and real-time monitoring systems can help in predicting maintenance needs and preventing failures, ensuring the uninterrupted operation of renewable energy systems.

- Automated Adjustments: In solar tracking and wind turbine applications, smart technology can enable automated adjustments to optimize performance based on real-time data.

Helical gears are indispensable in the efficient and reliable operation of renewable energy systems. Their unique design features make them well-suited for applications in wind turbines, solar tracking systems, and hydroelectric power plants.With the advancement in technology advances, the performance and capabilities of helical gears are set to improve, further solidifying their role in the renewable energy sector.

Embracing these advancements will be significant in the ongoing efforts to harness renewable energy more effectively and sustainably.

-

Sushmita Das is an accomplished technical

writer. Holding a degree in Electrical Instrumentation and Control System Engineering,

she brings a wealth of technical expertise to

her writing

View all posts

Post Views: 97