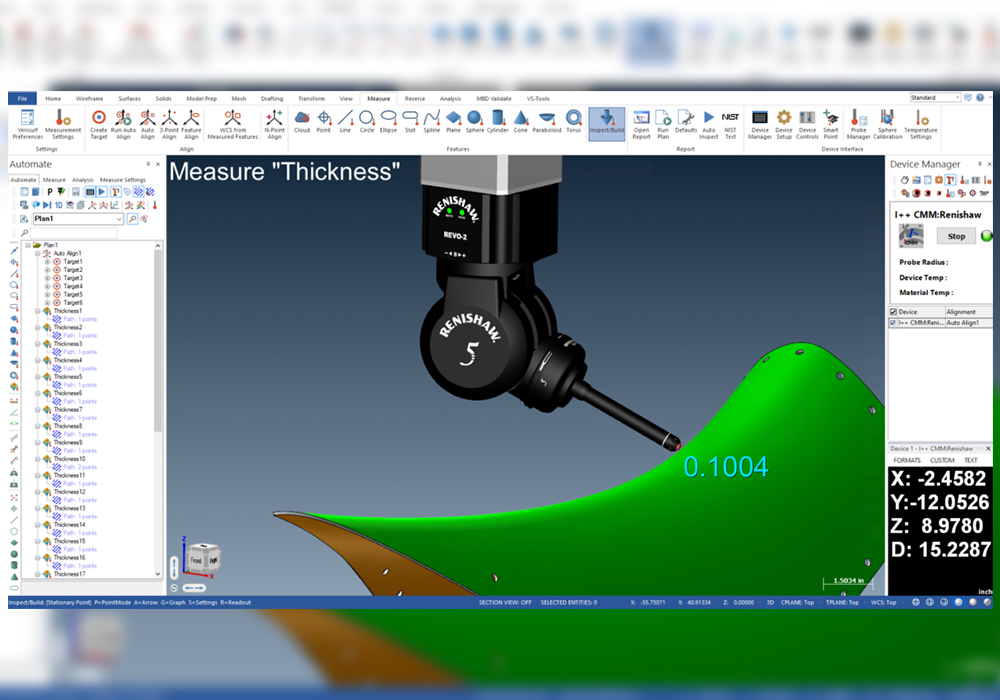

Verisurf Software, Inc. has announced its support for the Renishaw RUP1 (REVO Ultrasonic Probe), introducing an innovative solution for ultrasonic thickness probing. This advancement streamlines the measurement and reporting of thickness requirements, and the upcoming Verisurf 2024 release will showcase the integration of the RUP1.

Using the robust Dynamic Surface Points tool, Verisurf’s Inspection Plans now seamlessly incorporate ultrasonic thickness measurements. These measurements are meticulously stored and presented using a graphical balloon, providing recipients of the report with a clear and comprehensible thickness map associated with the inspected component. The RUP1 facilitates thickness evaluation for typical metal parts within the range of 1mm (.039″) to 20mm (.787″) in thickness, boasting an accuracy of .01mm (.0004″) on parallel surfaces and .100mm (.0039″) on wedged surfaces with an angle of up to 10 degrees.

Verisurf Software effectively operates Renishaw-equipped CNC CMMs via the Verisurf Device Interface (VDI), ensuring seamless communication with a diverse array of 3D measurement devices. The VDI empowers customers to choose their preferred devices while providing a standardized solution that comprehensively supports design, tolerancing, validation, machining, assembly, measurement, inspection planning, reporting, analysis, and reverse engineering.

Nick Merrell, Executive Vice President of Verisurf Software, Inc., emphasized the company’s unwavering support for Renishaw-equipped CMMs and standalone Renishaw products. Merrell affirmed the team’s commitment to consistently augmenting value through software solutions, manufacturing expertise, and engineering proficiency. Verisurf’s reputation for user-friendliness, stability, flexibility, and intelligent workflows contributes to heightened efficiency, quality, and throughput.

Verisurf stands out as the sole measurement, reverse engineering, and inspection software built on a comprehensive 3D CAD/CAM platform featuring intelligent Model-Based Definition (MBD). This distinctive approach ensures data integrity and facilitates the execution of metrology workflows within a seamless CAD environment, maintaining model-based digital continuity. The software’s compatibility with all CAD file formats, coupled with the universal communication capabilities of the Verisurf Device Interface (VDI), establishes Verisurf as a versatile solution for all 3D measurement devices. The modular design enables users to effortlessly transition between reverse engineering, inspection, and tool building, efficiently capturing and processing measurement data for a wide range of 3D metrology applications, thereby ensuring repeatable process control throughout the manufacturing enterprise.