In the bustling world of industrial machinery, where efficiency is paramount, the unsung heroes often reside within the intricate design of pumps and compressors. At the heart of these powerhouses lies a critical component – the bearing. In this exploration, we delve into the crucial considerations behind bearing design for pumps and compressors, shedding light on the nuanced factors that keep these machines humming.

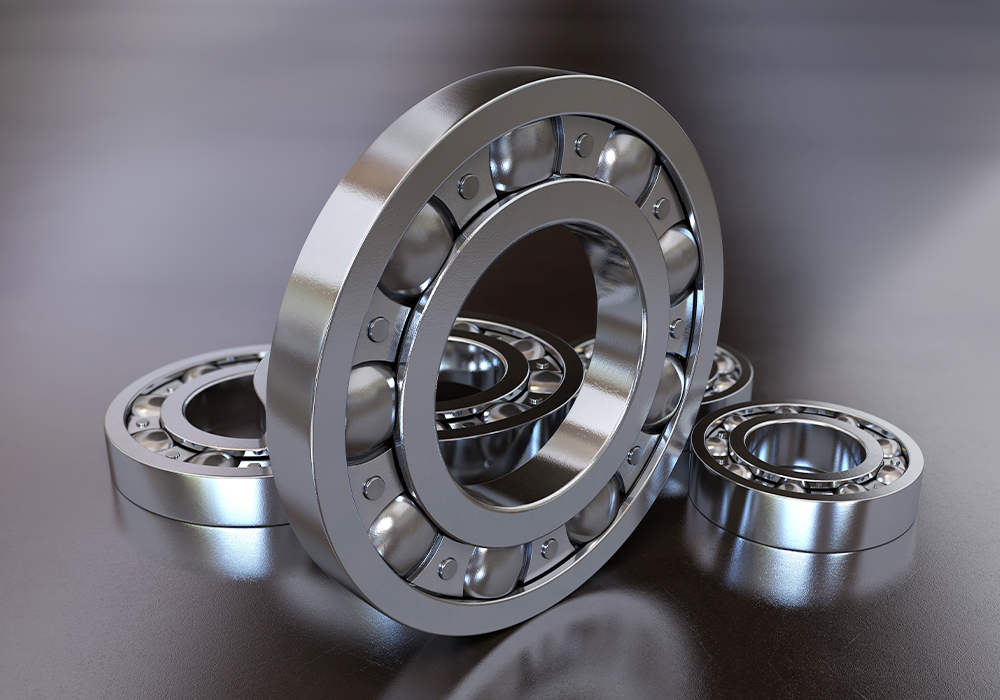

Before diving into the intricacies of bearing design, it’s essential to grasp the pivotal role these components play in the smooth operation of pumps and compressors. Bearings are responsible for reducing friction, supporting loads, and facilitating rotational movement. In the context of these dynamic systems, selecting the right bearing design is akin to choosing the perfect foundation for a skyscraper.

One of the primary considerations in bearing design is understanding the load characteristics that the pump or compressor will encounter during its operational life. Radial loads, axial loads, and moment loads – each machine demands a specific bearing type capable of withstanding the forces exerted upon it. Engineers meticulously analyse these loads to determine the optimal bearing configuration, ensure the longevity and reliability in the face of demanding conditions.

Pumps and compressors often operate in environments characterized by extreme temperatures and high rotational speeds. These factors pose a significant challenge in bearing design. Engineers must select materials and lubricants that can withstand the heat generated during operation. Additionally, the bearing’s design must minimize friction, reducing wear and tear as the machine operates at varying speeds. Striking the right balance between material selection and lubrication is crucial for ensuring the longevity of the bearings.

Industrial settings are known for the presence of contaminants such as dust, dirt, and moisture. These intruders can wreak havoc on the delicate mechanisms of bearings, leading to premature failure. As such, engineers focus on designing seals and shields that effectively protect the bearing internals from contaminants. Selecting the right sealing arrangement is paramount, as it directly impacts the bearing’s ability to endure harsh operating conditions.

Lubrication is the lifeblood of bearings, and choosing the correct lubrication strategy is imperative for optimal performance. Engineers must decide between oil and grease lubrication depending on factors such as operating speed, temperature, and load. The lubricant not only reduces friction but also dissipates heat, preventing the bearing from overheating. Regular maintenance schedules are established to ensure the continuous supply of fresh lubricant, mitigating the risk of premature wear.

In the quest for efficiency, minimizing noise and vibration becomes a crucial aspect of bearing design. Pumps and compressors operating at high speeds can generate significant vibrations, which, if left unchecked, may lead to structural damage and decreased efficiency. Engineers employ advanced techniques such as precision balancing and vibration analysis to optimize bearing design, ensuring a harmonious and quiet operation.

The materials used in bearing construction are carefully chosen to withstand the harsh conditions of industrial applications. Common materials include steel, ceramic, and polymers, each offering unique advantages. Additionally, advancements in bearing technology, such as the integration of sensors and smart lubrication systems, are pushing the boundaries of performance and reliability.

In the intricate dance of machinery, the significance of bearing design for pumps and compressors cannot be overstated. As engineers strive to optimize efficiency, reduce downtime, and enhance the overall lifespan of industrial equipment, the meticulous consideration of load characteristics, rotational speeds, temperature extremes, contamination resistance, lubrication strategies, and noise and vibration factors remains paramount. Bearing witness to the seamless operation of these powerhouses, it becomes evident that the heart of machinery lies in the careful craftsmanship of the often-overlooked bearing.