E-Mobility is changing the gear market at an incredibly rapid pace, and the software is adapting to meet these new challenges

Matthew Jaster, Senior Editor

Electrification is everywhere—from the cutting tools to the machine tools as well as the gear noise analysis and the new transmission technolo-gies—we’re living in a world of E-mobility. The software is no exception. Many of the gear design software suites available from the likes of GWJ Technology, Dontyne, KISSsoft, Romax Technology and SMT have been carefully prepping for the electrification trend as well as the slow and steady move toward systematic design in gear manufacturing.

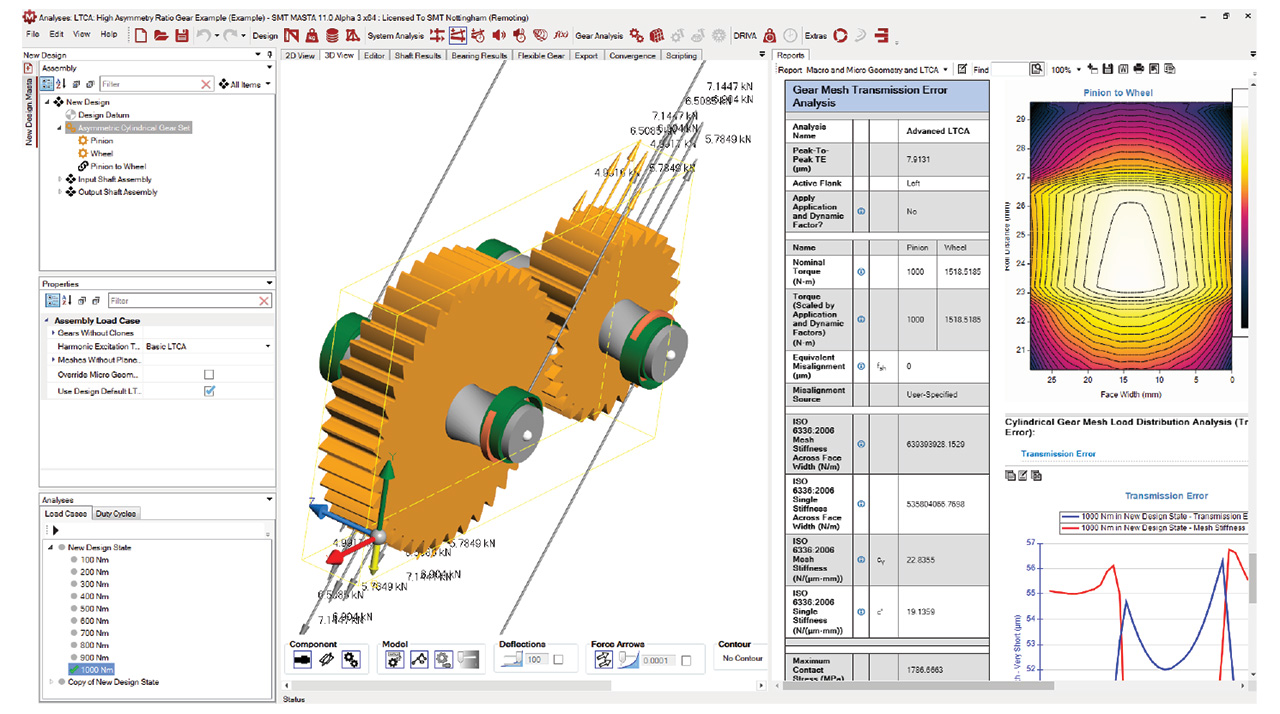

In general, electrification has changed how vehicle engineers think about noise, according to Paul Langlois, software engineering director at SMT. “With IC engines, the combustion noise masked gear noise to some extent. In electric vehicles this is no longer the case. This has played into a strength of the MASTA software which already had exceptional accuracy in the analysis and prediction of NVH issues. What we have added is the ability to look at the full powertrain system and understand excitation from the gear and the electric motor and the response of the system model. The focus on noise means that the majority of EV transmission gears are finish ground rather than shaved or honed. Using a generating grind system (worm grinding) can introduce other complications such as adverse bias or profile hollows if the gear design and the manufacturing process are not aligned properly. The manufacturing modules in the MASTA software, which SMT have been refining for nearly 20 years, can help designers get to the right solution faster,” Langlois said.

Along with the electrification of cars comes the demand for low noise gearboxes, since the missing motor sound of a combustion engine plus much higher input speeds of an electric motor make the remaining gears much more sensitive concerning noise emissions. The buzzword—as mentioned—is “NVH.”

“We offer advanced tools for noise sensitivity analysis, so that very early in the design state the engineer can already check for critical speeds, resonance frequencies and the system response on excitations from the gear meshing of the motor. For ongoing calculations in this context, we work with a partner in the field of vibration analysis software, accepting that we cannot be the best in class everywhere. So, we offer a thirdparty product for multi body dynamics in a package with KISSsoft,” said Dr. Stefan Beermann, CEO, KISSsoft AG.

For the manufacturing topic, Beermann handed the analysis over to his esteemed colleague Dr. Antoine Türich at Gleason: “E-Mobility is changing the gear manufacturing twofold: Less gears but with much higher quality requirements. This results in much tighter tolerance requirements, which are harder to achieve and to control. Hence, hard finishing such as grinding, honing or hard power skiving is more or less mandatory for all e-drive gears. But even with these hard finishing processes, it is not easy to achieve and hold these tight tolerance requirements under production conditions. The traditional sampling measurement including statistical control will step by step be replaced by up to 100% inline inspection concepts,” Türich said.

At Romax Technology, the push towards electrification is in the company’s DNA.

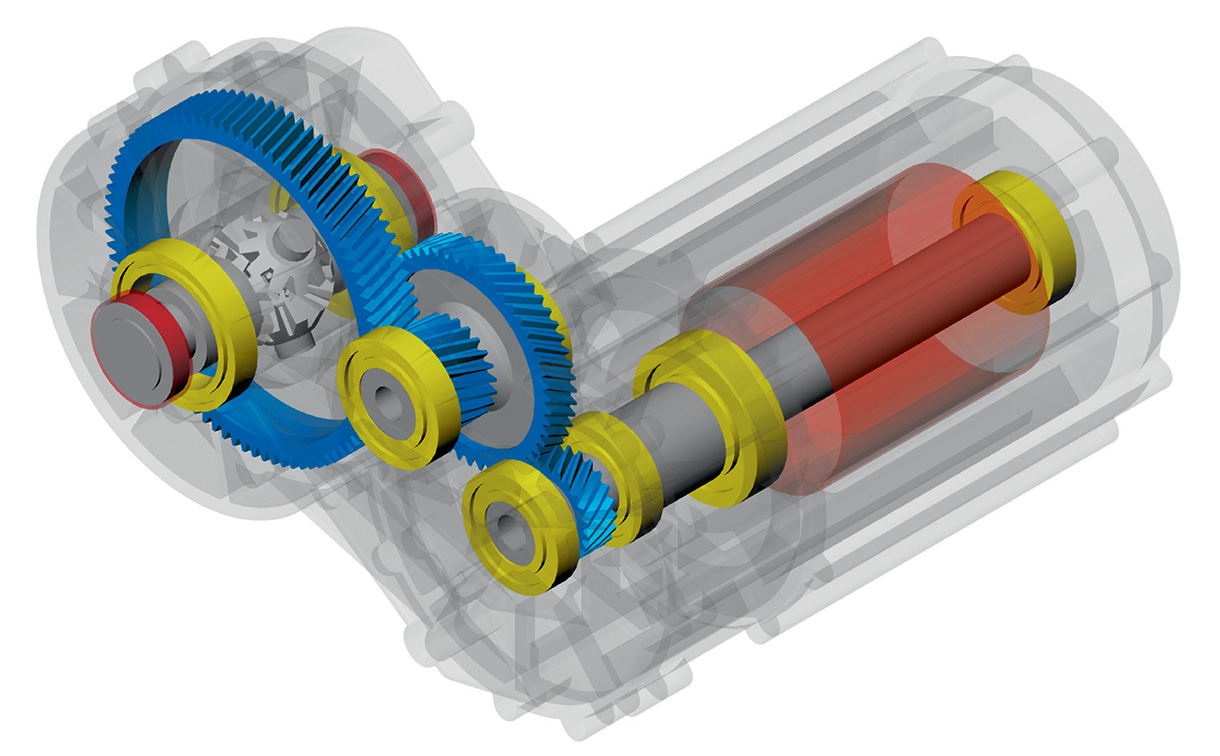

“Drive systems, and especially electrified ones, are becoming more and more integrated and the product development tools and processes need to reflect that, which is why Romax tools consider the electric machine together with the drivetrain components in one system that is always analyzed in a coupled way. For example, our customer Valeo was recently awarded an Automotive News PACE award for its innovative 48V eAccess powertrain solution for small urban vehicles,” said Travis Histed, business development manager, Americas – System Dynamics, Romax Technology.

These new architectures need to be considered from a system-level perspective in order to properly optimize the components individually; they all must come together to form a complete system that delivers on durability, efficiency, noise, and cost, Histed added.

“Romax tools can integrate the electric machine into the mechanical system so that these interactions can be understood and tuned.” Mike Fish, director at Dontyne Systems, said that there’s a determined—and quite correct—push towards closer integration between design software

with production equipment that falls under the ‘Industry 4.0’ umbrella. “This has been our intention since the company’s formation in 2006 with the creation of the Gear Production Suite. “The fast and efficient flow of design data around a plant is essential and expensive when

not controlled accurately. Our software provides that platform,” Fish said. The move toward electrification has been very beneficial for Dontyne as it has increased the requirement. “Flexibility and ease of use has helped companies produce designs quickly,” Fish added. “Manufacturing simulations have allowed companies to check correct production before cutting metal.”

We asked our software experts to describe the trends and relevant topics currently taking place in the gear and gear drive markets.

NVH is one if not the key driver in e-mobility and requires all aspects to be considered, from the correct gear design to the appropriate manufacturing and finally the gear inspection to make sure that the produced gear will not make any noise problems, said Beermann.

“Increasing noise requirements together with higher power density make tolerances tighter than ever. An interesting aspect in the future will be to analyze during the design process whether the desired modifications and tolerances will be possible to be manufactured with certain hard finishing processes. Therefore, manufacturing simulation within the design process will certainly gain higher importance,” Beermann said. “Currently, a lot of new players are entering the EV-market who have limited experience with gear design and manufacturing. Putting more “intelligence” and know-how into the design and simulation process will help those new players to become successful.”

Romax is closing the loop between software and hardware. “With our joint offering with Dontyne, it is now possible to simulate the gear manufacturing process in Romax and incorporate those simulated gears back into your Romax system model. Now that we are a part of Hexagon’s Manufacturing Intelligence division, I expect to see this loop fully close and CAE to play a much bigger role in the production and quality control parts of the process in the future, among other things, as part of the digitization megatrend,” Histed said.

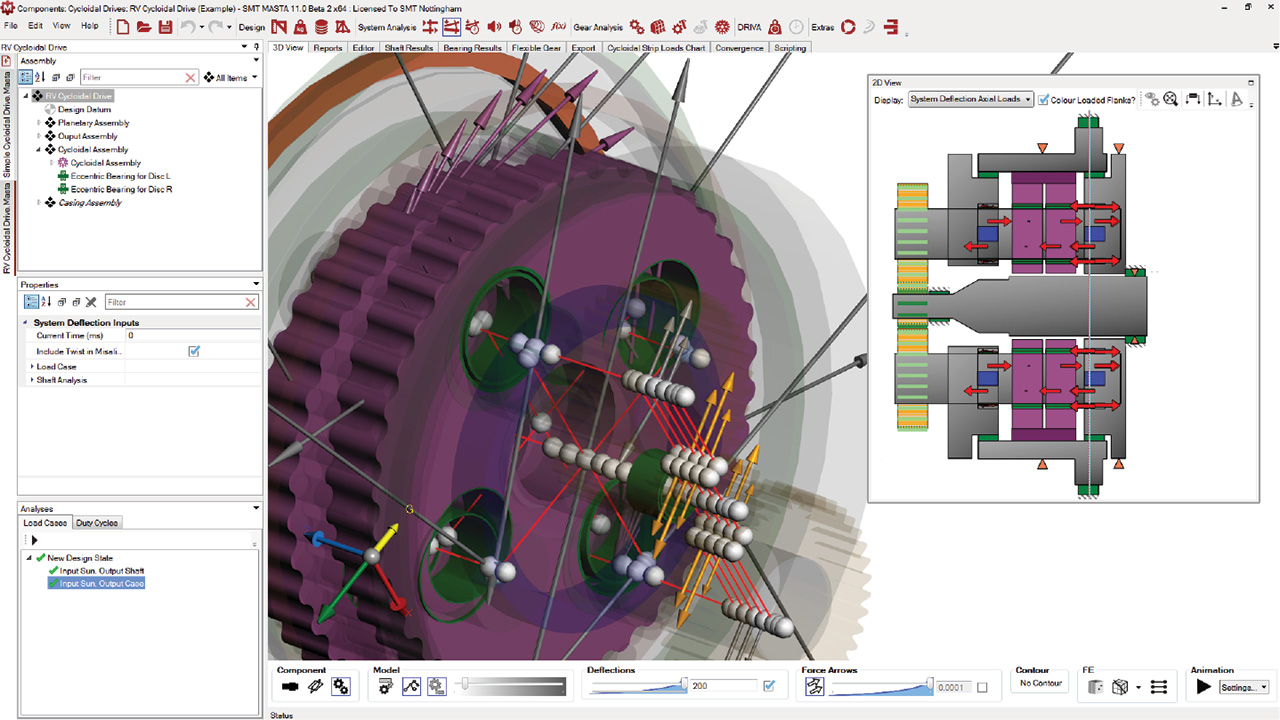

xamining cycloidal drives with SMT

Additionally, Histed believes democratization is a major trend in engineering software. “We are continually looking for ways to make our products more intelligent, easy to use, and flexible to fit into the constantly evolving industry processes. This enables best practices and intellectual property to be embedded into robust systems, helps empower engineers who are new to their field and frees up scarce domain experts to continue innovating,” he said.

At SMT, the first trend is that tolerances are getting tighter. For automotive gears the allowable tolerance on micro-geometry can be in the order of +/-2 microns. This is driven heavily by the NVH requirements for electric vehicles. Before this time general tolerances on micro-geometry were in the order of +/-10 microns. Having a better understanding of NVH and how to design the gears for a system using software like MASTA can mean these tight requirements can be relaxed. Robustness studies can be easily performed to understand the performance with a full tolerance band. This can only happen if the gear designers and manufacturing teams work more closely together.

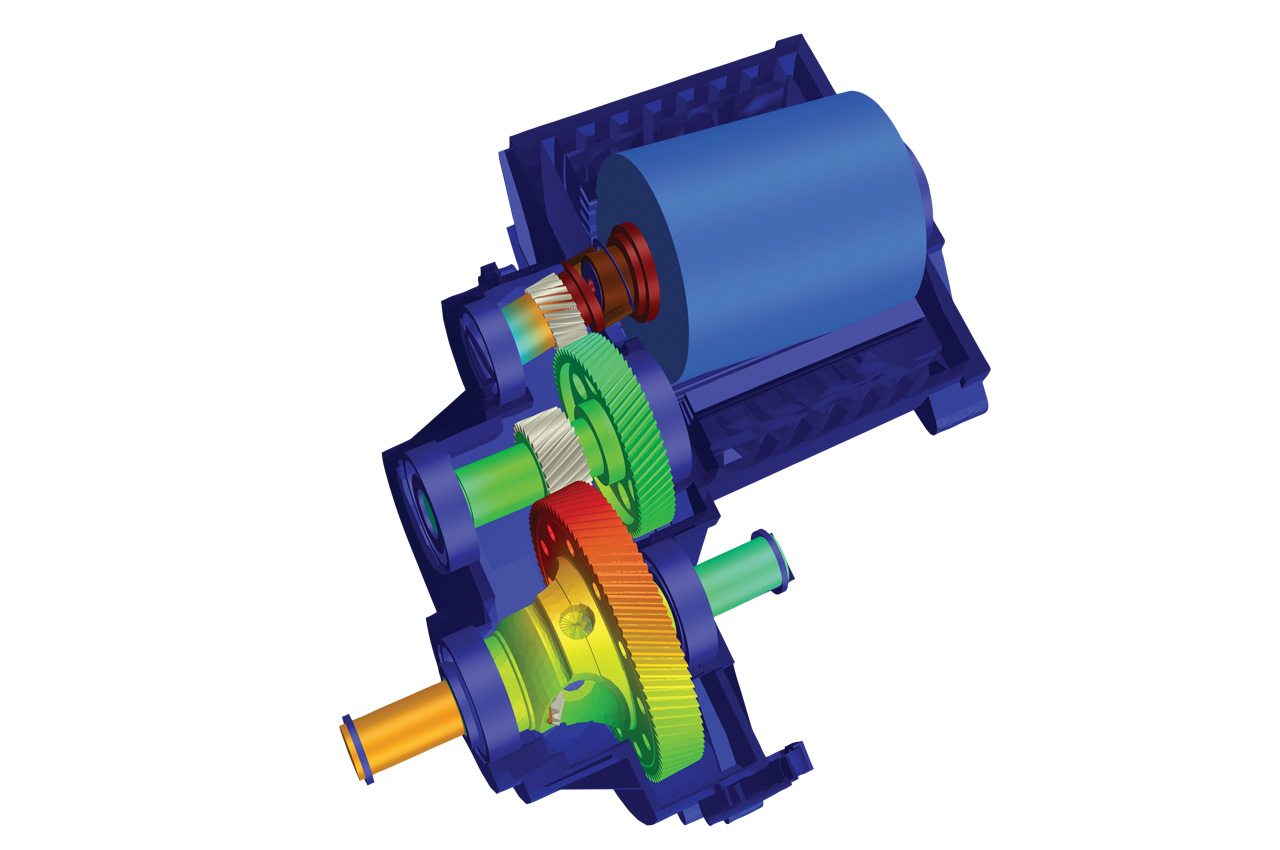

Gearbox with housing (courtesy of KISSsoft).

Better use of materials is another trend. “SMT has previously completed research work on plastic gears, and these will start to see more common use in precision applications including robotics, which is likely to surge as a marketplace in the next decade or so. Also, for steel gears the understanding of material limits will improve to allow for a better selection of appropriate gear steel for an application. Many organizations still use generic material properties to cover many different types of materials. This can lead to oversized designs as extra safety factors are built in,” Langlois said.

The final, and inevitable trend is 3D printing (or additive manufacturing). The manufacturing methods are improving, and gears manufactured by this method could provide some geometric advantages and opportunities to lightweight. This will initially be dependent on application, but in the long-term 3D printing may become and major manufacturing method for all gear types, Langlois said.

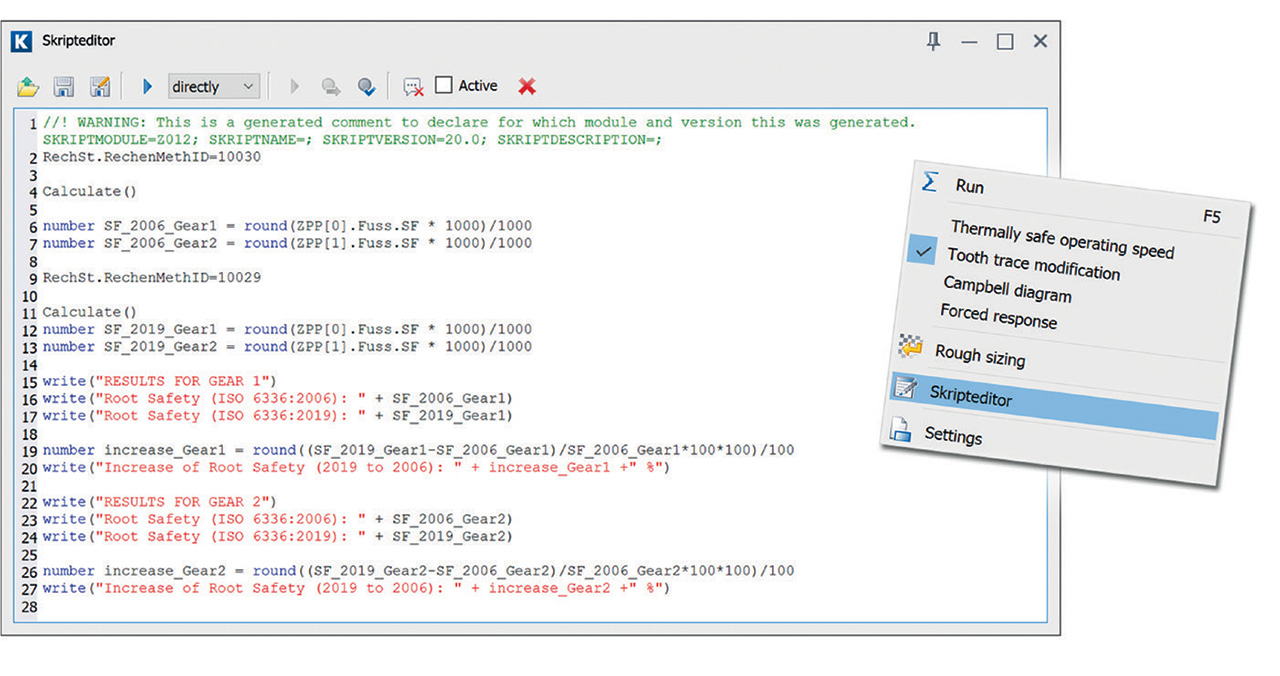

Dontyne has added programmers in the last two years to expand the company’s ability to flex to client’s specific requirements. Customization—as it turns out— is another trend that is changing the software game, according to our experts. “From the beginning, KISSsoft was

highly adaptable to the user’s needs.

You can change the default values in the dialogs, the data in the database (material, tolerances, ….), the contents and appearance of the reports, and the directories used on the hard drive. In addition, you can define design rules that are checked with each calculation and if this is not enough, we added a script language named “SKRIPT” in the software to do additional calculations, provide custom interfaces or automate processes,” Beermann said. “Some of our customers are using KISSsoft only in the background of their own software via the COM interface. So, our problem is usually not how the user can adapt something to his needs, but which is the best way of many to do that.”

At SMT, customization of the product to specific customer needs has always been a driving focus. “We have had two complimentary approaches to this. On the one hand we have very close working relationships with our customers. We encourage continual feedback on our products and the development of MASTA is driven by our customer’s needs. On the other hand, we have developed advanced scripting functionality. “

MASTA scripting capabilities allows any customer to write custom scripts to input data, output data, run analysis or create automations. This means that the customer can integrate the software with existing tools and communicate with MASTA via an extensive API. The MASTA API exposes nearly all of the underlying parameters, calculations and outputs to the user.

“SMT have generated a number of example scripts including model import and export via the REXS data format. Scripting could also be used for any custom data format. As MASTA’s scripting functionality is accessible via common software languages which are already familiar to engineers, such as Python, C# and Matlab, the engineer can start writing scripts without any need for learning a new scripting language,” Langlois said.

Histed added that companies are rapidly evolving to deliver robust gearboxes for new architectures as fast as possible. To do this they need more collaborative tools that allow gear, bearing, structures, and motor designers to work together and reduce reliance on redundant tools and repetitive model building. “Romax tools are focused to give each discipline the capability it needs to optimize the gear or bearing or housing design, while having a common modelling platform that allows them to collaborate and communicate in a much more effective way.,” Histed added.

Examining asymmetric gears with SMT

Romax’s partnership with Hexagon Manufacturing Intelligence includes state of the art manufacturing and measurement technologies. “There is a very clear path of tools in our portfolio to go from “as designed, as manufactured, as assembled, as used” and feed data back at each stage to the design step. We are in a great position to leverage our existing technology and augment it developing practical applications of Industry 4.0 ideas,” Histed said.

With KISSsys, Beermann said the company has offered system software since 2000. “It does its job, however, the user interface is not the most modern one anymore. We are currently working on a new user interface that will be highly intuitive and gives the user more guidance. The general data structure also got a major update, accounting for the experiences we collected during the last 20+ years,” Beermann said.

SMT have always provided a full system modelling solution with the MASTA software. SMT has believed since its beginning that system level analysis of gear drive systems is essential for accurate results and insights. “The MASTA software is built to be intuitive to use and we have refined the speed of the modelling functions to give maximum benefit to our users. Most recently this has included 3D CAD integration that allows users to model directly from 3D CAD. Users can also import housing and structural CAD model and convert them easily into FEA models. The user interface and fast modelling capability means that the software can be used for initial concept layout without the need for additional concepting modules. The software also includes bearing model catalogs from all the major bearings suppliers,” Langlois said.

With a continued push to solving the skilled worker shortage in areas like gear manufacturing, these software organizations continually examine how their software suites can assist on the shop floor.

Software such as MASTA can improve the efficiency of the design and development process for a geared drive or transmission. The manufacturing modules can be used to simulate the cutting process before cutting metal which can reduce the amount of rework. “MASTA’s high accuracy means that typical development issues can be found earlier in the design cycle. This reduces the burden of development testing. An example is contact pattern development. Traditionally the refinement of contact patterns was an iterative method using testing. Because of the accuracy of MASTA this is now performed virtually by many of our customers,” Langlois said. “MASTA software also has the capability to be automated using the unique scripting function. The use of this in the design, development and manufacturing can remove the need for manual repetitive

analysis tasks, such as copying data from one system to another without errors.”

Being able to simulate manufacturing errors and assess them very quickly using Romax tools allows the designer to identify system sensitivities and design around them in the first place.

“Error-proofing the process by directly producing gear manufacturing files from the design software (including simulated manufacturing deviations) ensures that the manufactured part is much closer to the designer’s intent. As mentioned previously, a key to tackling this issue is democratization, and embedding of knowledge and best practices in software workflows. For example, our joint development with Dontyne of cylindrical gear manufacturing simulation embedded in Romax can be fully automated, enabling design space exploration and manufacturing variability studies. It is also able to take common design parameters as inputs and automatically estimate the tooling parameters so that the user does not have to have a deep understanding of gear manufacturing. Considering the particular skills and needs of the person who is going to use a given feature is integral to our product development process” Histed said.

Beermann added that software might cover up some shortcomings of skilled personnel on the shop floor, but it will never be able to really replace it.

“In the end, software can increase the efficiency and maybe help with some expert knowledge crystallized in code. Still, if the personnel are not sufficiently skilled or simply not there, the second part of the equation is missing. Automation will be more important in this regard if you find the even more skilled personnel necessary to set up the automation.”

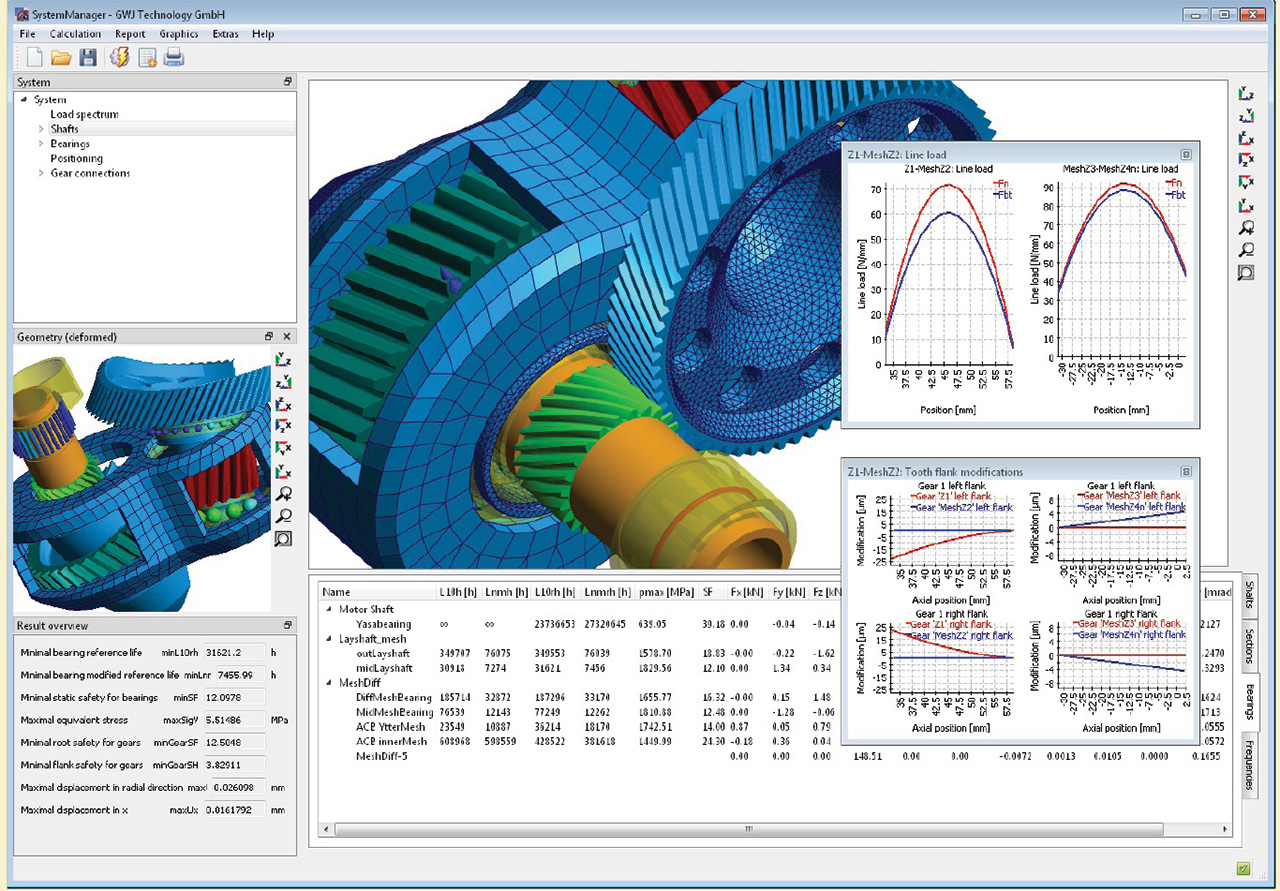

Following the success of last year’s workshop, GWJ Technology, organized once again the three-day online workshop “Gear Calculation, Design and Optimization – System Calculation” for Formula Student teams. The virtual workshop brought together about 60 participants from over 30 different racing teams. The program was very diverse.

In the first part of the workshop, the focus was on the introduction to gear calculation and the calculation software eAssistant. Especially the basics for calculation and dimensioning of the geometry and the load capacity of cylindrical gears and planetary geartrains were covered on the first workshop day. Terms and principles were discussed that are essential for the calculation of gears. With the web-based calculation software eAssistant, the attendees got an ideal tool for the following days.

In addition, a lot of tips and hints as well as optimization strategies were shared. The participants were also given some insights into the eAssistant 3D CAD plugins to easily generate 3D models with just a few clicks. The focus turned to the eAssistant SystemManager on the second day. System Manager is a software extention for the configuration and calculation of entire systems of machine elements, e.g. multistage gearboxes, shift gear transmissions or different types of planetary geartrains. After introduction to the System Manager basics functions and an in-depth look, the attendees got the idea of what they could do with the software. SystemManager software offers many possibilities—from the fast and easy design and calculation of complete systems to the automatic meshing of housings and planet carriers.

So, the Formula Student teams get the chance to efficiently integrate the eAssistant SystemManager into their projects and to use the potential of the software in the long term. The third day provided practical examples and this session evoked many questions and comments from the participants which in turn generated a lot of valuable discussion that resulted in newly gained insights for the students. The final day ended with tons of new ideas and fresh input and most of all inspiration and drive for future projects.

www.dontynesystems.com

www.kisssoft.com

www.romaxtech.com

www.smartmt.com