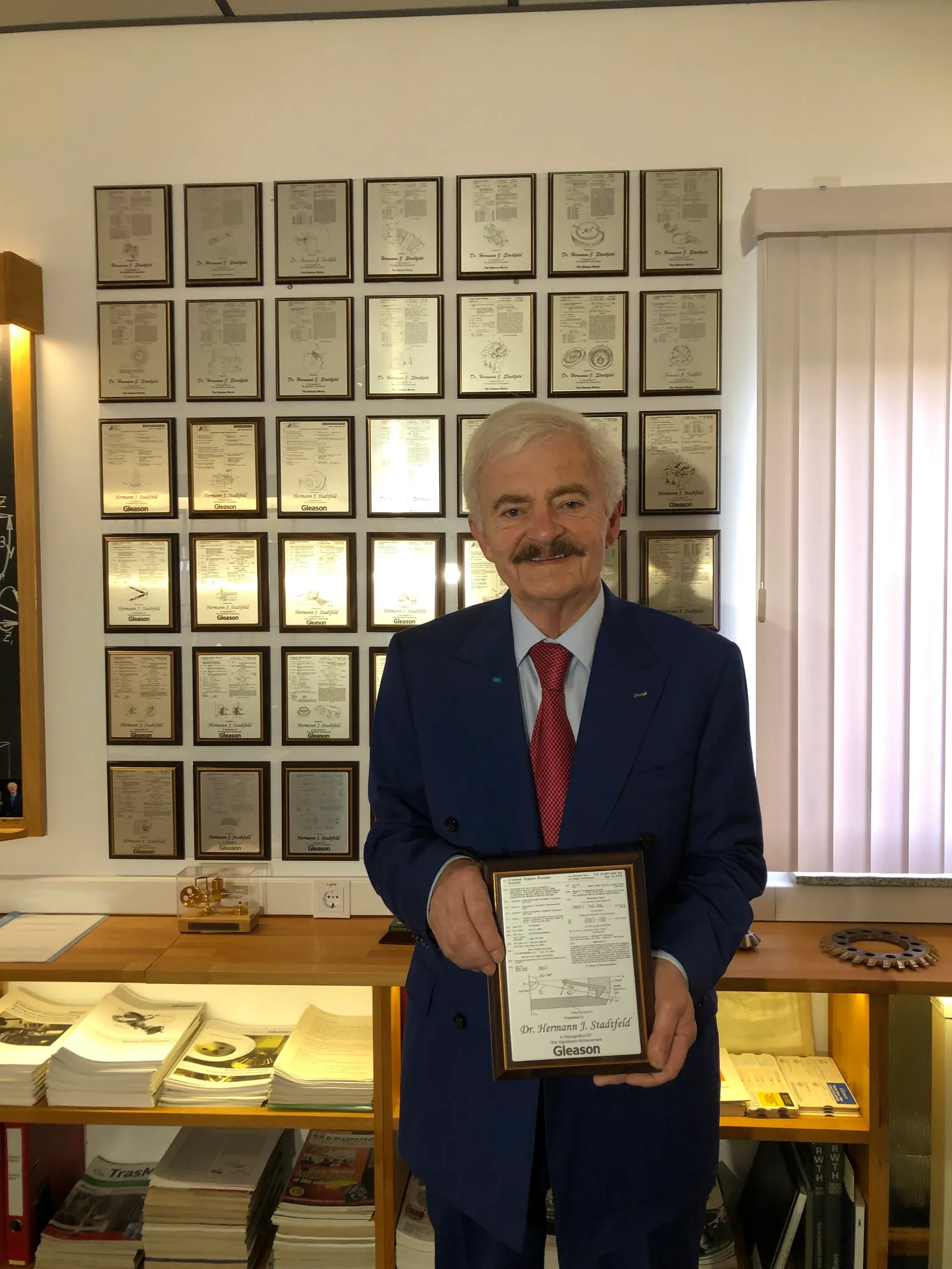

Gleason Corporation’s Prof. Dr. Hermann J. Stadtfeld, Vice President of Bevel Gear Technology and R&D, has been awarded a new patent for his latest invention, “Psychoacoustic Tooth Flank Form Modification”—also known by its working name MicroForm. The innovation marks his 70th patented invention, continuing a career dedicated to advancing the science and manufacture of bevel gears. Gear Technology caught up with Dr. Stadtfeld to field a few questions about this latest milestone.

Bevel and hypoid gears will become quieter without increasing the gear quality. This is important for the mass production of bevel gears for electric vehicles, but also important for conventional vehicles.

More and more bevel gears are ground, which poses the problem, that ground gears, which have a very low indexing error, are often noisy, due to the precisely timed impact of the teeth, getting into mesh. In case a located tooth contact is located, with low motion error within the contact pattern, this noise can be reduced by increasing the gear quality even more and by adding additional finishing operations, like fine honing, polishing, or lapping. The result is a quiet gearset, manufactured at twice the cost. The new patented technology allows to achieve quieter operating bevel gears, which are even quieter than fine honed, polished, or lapped gears, by simply grinding them with MicroForm turned on. MicroForm will not increase the grinding time and therefore produce premium, noise-reduced sets at the original manufacturing cost.

Gears and, in particular, bevel gears have become my life. Gears are the most complex machine elements, and the machines that produce them are the most complex and sophisticated machine tools in the industry. The gear theory, the gear mathematical software, as well as the production machines and the processes they perform, are fascinating for me. It is a blessing to be able to do fascinating work every day, and work becomes a hobby.

The notion of reducing gear noise started with conventionally propelled luxury vehicles. Then the need for especially quiet transmissions in electric vehicles came up, forced by the low noise from the electric motors, which made transmission noise more audible. In the meantime, also the manufacturers of truck construction and agricultural equipment also ask for transmission noise reductions. The fact that the cost per gear, made with MicroForm, does not increase vs. conventional grinding makes this new process very attractive for new bevel gear developments.