Tube Mill Roll Stand Gearbox

Simply put, they are gearboxes that are tailor-made. Typically, they are:

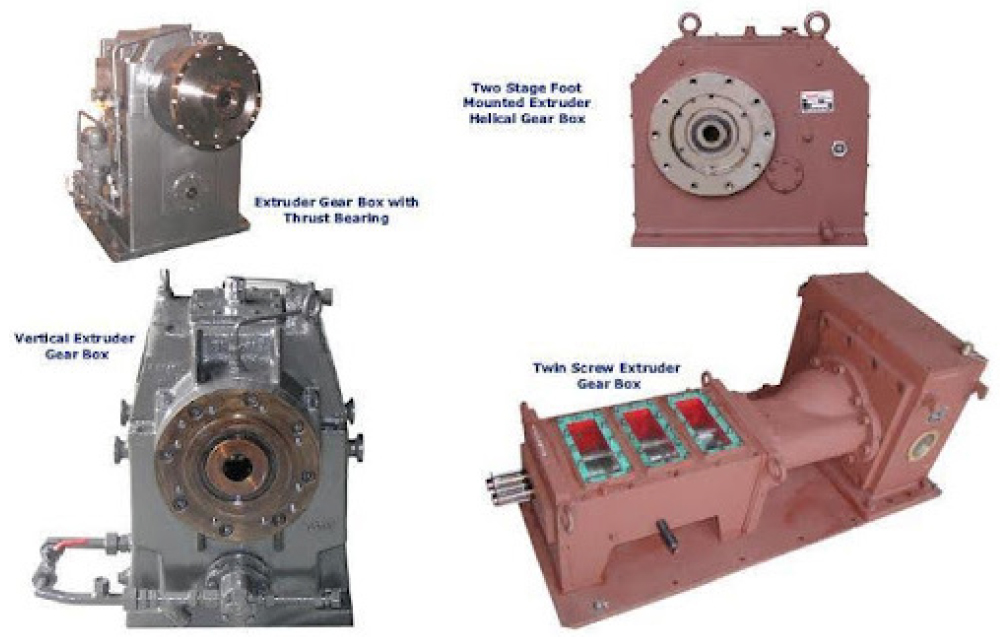

Certain customers prefer to develop gearboxes to specific applications like an extruder, agriculture, pharmaceutical, and so on. To take care of these requirements, gearbox manufacturers developed a series of gearboxes for extruders. These ensure that customers select from catalogues based on motor power, reduction ratio, and screw size. There are different types of extruder gearboxes that are developed like the single screw extruder gearbox, and the twin screw extruder gearboxes.

Extruder Gearboxes

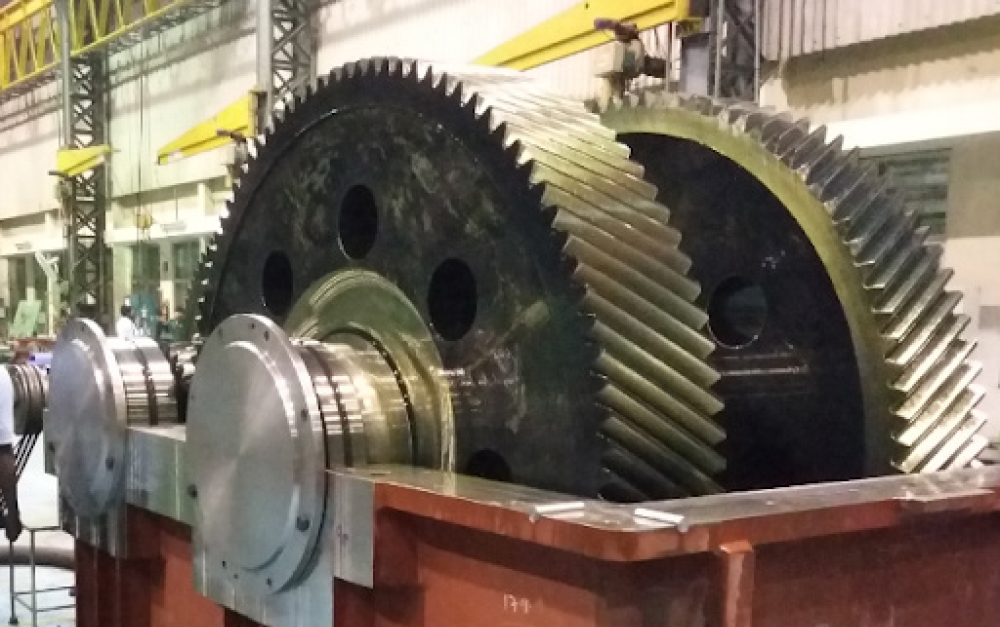

In any segment or applications, there are specific gearboxes in operation. These may be supplied by overseas /domestic suppliers. It’s important to note that these gearboxes may be in operation for anywhere between 20 to 30 years, therefore customers may find it difficult to get spare parts or a complete replacement for them. In this scenario, customers expect gear manufacturers to give them new gearboxes as per the existing gearbox dimensions. In some cases, the customer would prefer to develop a new gearbox with an enhanced rating without changing the foundational details.

While developing import substitution/replacement gear boxes, manufacturers keep the external dimensions as per the existing one, and accordingly modify tooth parameters as per their standard.

To improve the rating, gear manufacturers now design by selecting appropriate materials/tooth parameters.

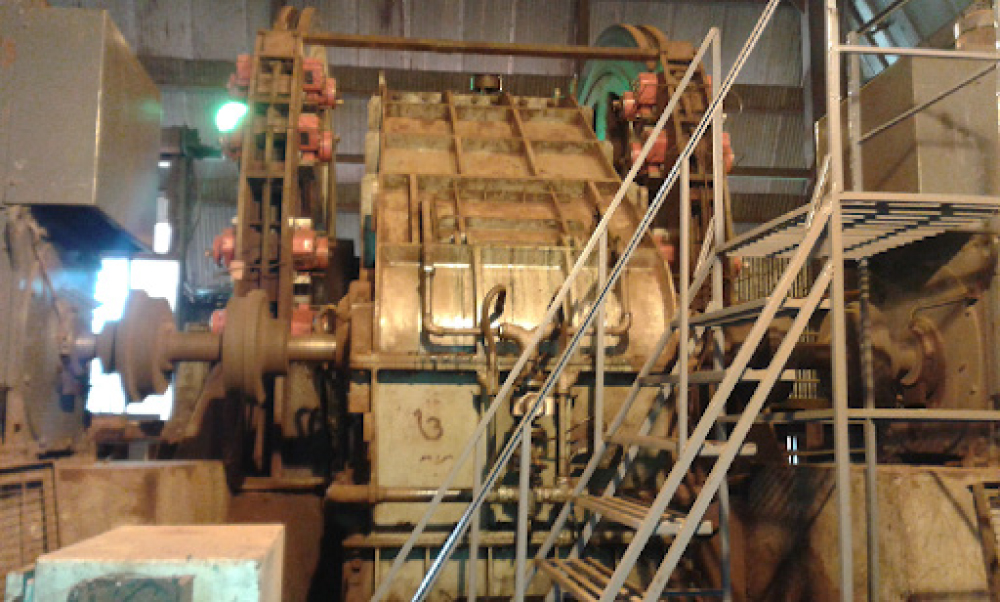

Sugar Mill Gearbox

Conveyer Gearbox

Some of the steel, cement, power, sugar, paper, mining plants have imported equipment in their operations. These projects may have been commissioned by overseas OEMs. For instance, the majority of power plants have Chinese imported gearboxes, and the customer would prefer to develop the replacement indigenously.

Often, the customers want to develop spares for imported gearboxes. In this requirement, gearbox manufacturers have to measure complete dimensions as per sample.

Here, manufacturers keep the major dimensions like centre distance, ratio, bearing seating, oil seal seating area and tooth parameters as per their standard, so that during gearbox assembly, they are unlikely to face any issue.

The OEMs want to develop gears for their machines as per their design. For example: machine tool, railway, pharma, printing, extruder, textile, and mining equipment.

In India, there is a huge requirement for replacement gearboxes as well as loose gear components.

End-user segments such as steel, cement, or power often have imported gearboxes in their plants, and this poses a challenge for them as there is a struggle to develop spares/replacement gearboxes.

A solution for this is for gearbox manufacturers to have a dedicated business development team who have an adequate hands-on experience for taking measurements onsite, and to get these to the market.