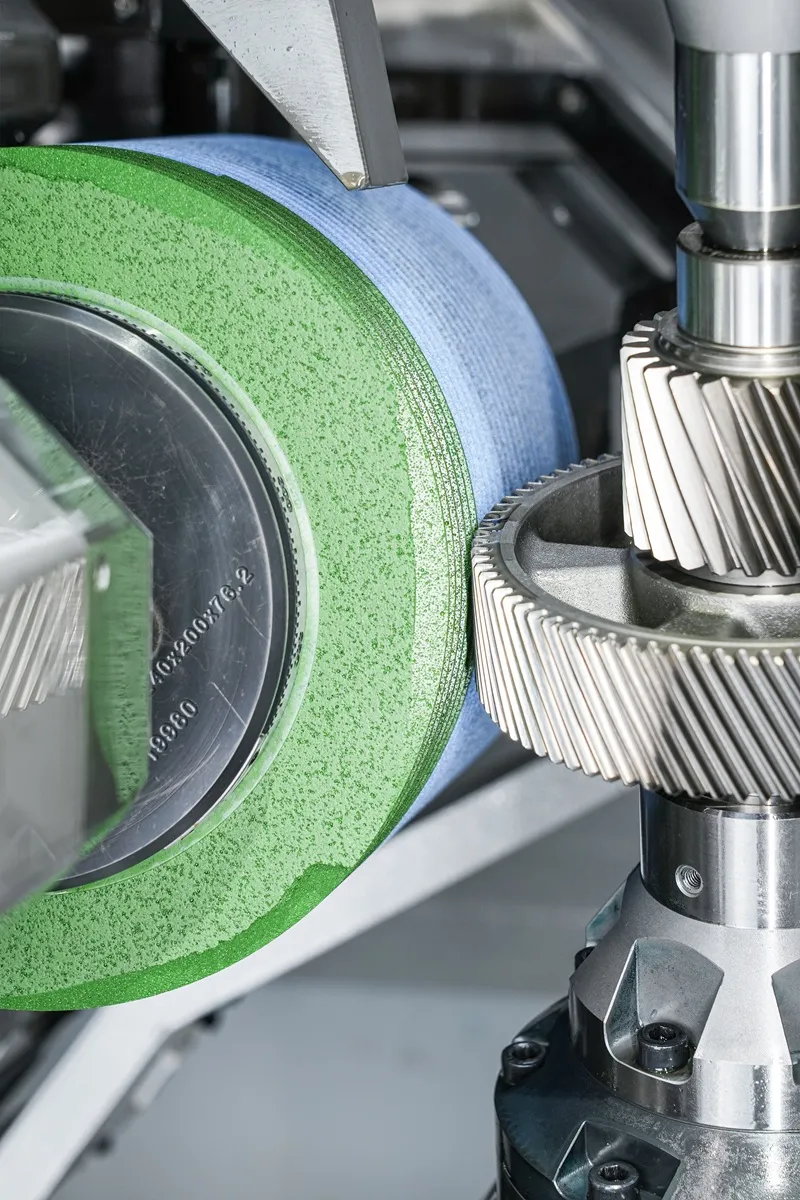

Liebherr-Verzahntechnik GmbH (Booth #519) will highlight its latest developments in twist-free generating grinding, which include process optimization for asymmetrical gear teeth and the integration of fine grinding or polishing in a single machining cycle. Updates to machine kinematics and software functions now allow the use of dressable grinding worms at cycle times comparable to conventional generating grinding, with improved control of surface finish and profile accuracy.

The latest twist-free generating grinding process enables more flexible shift strategies. Enhanced kinematic control allows operators to separate shift position from shift length, minimizing profile deviations and allowing for precise definition of diagonal zones using the LHGearTec control interface. By segmenting the grinding worm to alternate between roughing, finishing, and polishing regions, users can influence tooth flank geometry and surface structure with greater precision.

These developments support applications requiring targeted load distribution, reduced excitation noise, or high flank surface quality. Standard dressing tools may be used, and double-sided dressing is supported, reducing tooling complexity and cost.

Liebherr’s technology is applicable to a broad range of transmission components, including e-mobility and heavy-duty industrial gearboxes. The process enhancements are supported by the rigidity and stability of Liebherr’s machine platforms and are designed to reduce both machining time and the number of required finishing steps.

liebherr.com