Modern engineering processes demand high quality and consistent performance. Naturally, the accuracy of the machining process required is very high and is difficult to achieve. Honing is one such highly accurate finishing operation.

Honing is a little stock removing finishing operation that requires high dimensional and geometrical accuracies, and a good surface finish. In this process, an abrasive grinding stone is rotated and reciprocated with controlled pressure on the surface of the hole. The rotation and reciprocation of the spindle are closely monitored to achieve the desired result. In short, honing is the process of finishing a hole by removing less material. It is used for parts that require high geometrical accuracy with a good surface finish.

The following are typical examples of honing applications: Valve guide, cylinder liner, connecting rod, rocker arm, gear shifter fork, gear, yoke, sprocket, slider block, engine parts, hydraulic directional control valve, spool, hydraulic motor part, etc. The honing process is also used with great advantage in aerospace components, turbo charger components, fuel injection components, refrigeration components and so on.

Khushbu Engineers initially developed the traditional manual horizontal honing machine. Manual honing is a highly skilled operation. Therefore, the productivity of the machine is lower in the case of conventional honing. Here, the accuracy and productivity are inversely proportionate. Over a period of time, customers demanded a highly productive machine with high bore accuracy. Also, operator dependency was expected to be reduced.

A new concept of Single Pass Honing with Multi pass Honing is developed to take advantage of close size control of the Single Pass, with a cross hatch pattern by Multi Pass Honing.

The machine has one vertical slide with 3 spindles for the Single Pass process. And the second slide is with one spindle for Multi-Pass, expansion type. The fixtures are mounted on a Rotary Indexing arrangement with 6 stations. One fixture is always available for part loading/unloading.

On cycle start after part loading, the fixture indexes to the first spindle. First, the honing pass is done. The second part is loaded in the fixture. The cycle is repeated till 3 tools are passed. For the next cycle, the part indexes to the multi-pass spindle; a cross hatch is generated while the three spindles complete the cycle. The finished part comes out in the next cycle. The rotary indexing arrangement allows loading/unloading one part every cycle. Hence one part is completed every cycle.

The latest development in honing is single pass honing technology. Using single pass honing technology, extremely close tolerances can be achieved repeatedly in production at a lower per piece cost. In view of the above, Khushbu Engineers developed a multi-spindle, single pass progressive honing machine. The technology used was to pass a diamond coated, pre-fixed size tool in the bore while rotating. It removes predetermined material in the bore. This is done 4-6 times in a row to remove 40 or 60 microns of material from the hole. Since the tool is diamond coated, the wear is very low. Passing the tool without expansion, one can speed up the operation. Due to the CNC System, this process is controlled with very high accuracy and consistency. The rigidity of the machine also plays a very important role.

Establishing new concepts is always difficult. With the help of the latest drafting technology and an experienced design team, we at Khushbu were able to develop the single pass progressive honing technology in the country.

At each stage of the design, it was necessary to perform a stress analysis and confirm the design. Equally important was the manufacturing part of the machine. Our first machine passed all the tests due to the selection of the right vendor who can get high specifications of manufacturing tolerance.

1. Number of spindles / tools ….4,6,8

2. Maximum diameter ……….. 40 mm

3. Maximum depth ………. 150 mm

4. Indexing accuracy ……….. 15 seconds

5. AC servo motor for axis movement

6. Feed ………. 2500 mm / min

7. Rapid traverses 2 ……… 5000 mm./min

8. Hole accuracy ……. 2-5 microns

9. Size repeatability (Cpk) .. 1.33

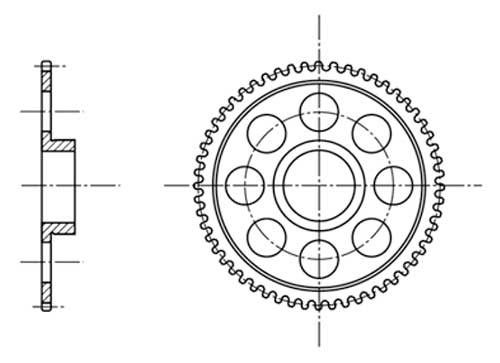

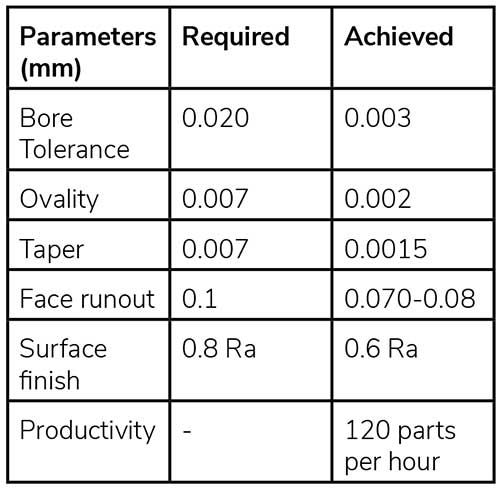

All transmission gears are honed to get a good fit on the shaft. The result is reduced noise, improved torque transmission, and improved vehicle performance. Normally after heat treatment, the hole in the gear shrinks by a few microns and the geometric accuracy deteriorates. The honing process improves geometry such as roundness, taper and surface finish. At the same time, the bore to face run out and gear PCD run out are kept intact.

Details

Material –Case Hardened steel

Stock for Honing – 0.040 mm

Diameter – 38.00 mm

Length- 18 mm

Number of passes- 4

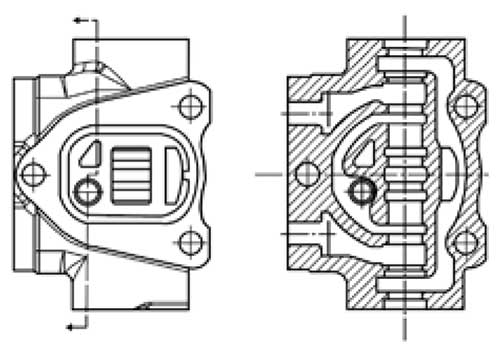

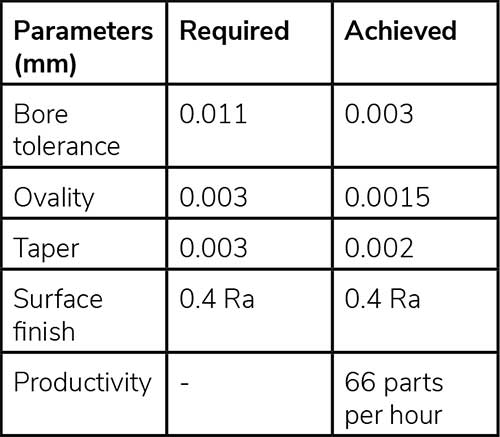

Honing a Hydraulic Valve is a little difficult. The fitment of the spool in the hole of the valve body is within 4-5 microns. That is, the geometric measurements of the hole have to be within 2 microns. Also, the surface finish required is 0.2 – 0.4 Ra. Here, the input accuracy of the hole is up to 20 microns. The honing process improves the roundness and straightness of the hole up to 2 microns.

Details

Material – Cast Iron

Stock for Honing – 0.030-0.040 mm

Diameter -16.00 mm

Length -127mm

Number of passes-4

This is the heart of the refrigeration compressor. The performance of the Air Conditioning unit depends on the accuracy and finish of the hole. Since the fitment of the piston in the hole is within 3-4 microns, the accuracy of the hole has to be in 1-1.5 microns. The Single Pass honing process not only achieves the accuracy of the hole and the surface finish of both holes, but also maintains the perpendicularity between the journal bore and the piston bore.

To sum up, the following are the distinctive advantages of the Honing Process:

• High dimensional and geometrical accuracy with smooth surface finish, faster than grinding.

• Higher productivity with high accuracy at a moderate cost.

• Smaller bores of diameter 3 to 48 mm and length of 180 mm can be honed faster than grinding, with high accuracy.

• Less skilled operator also can operate the machine easily.

The author, Ajeet Samani, is Director at Khushbu Honing based in Kolhapur

The author, Ajeet Samani, is Director at Khushbu Honing based in Kolhapur