Introduction

Traditionally, the concept has been to value the gear tool in terms of the number of times it can be re-sharpened till its “end-of-life”. With this concept, the tool manufacturer produced the gear tool with the highest amount of re-grindable stock within the confining parameters of accuracy and productivity. It must also be realized that the generating portion of the gear-cutting tool is an edge, resulting from the manufactured profile of the tool tooth flank and the sharpened or resharpened cutting face. With this, it becomes quite clear that the tool resharpening machine has a role to play in gear accuracy. In short, the dominant conventional concept of gear-cutting tools, especially gear hobs and gear shaper cutters, has somewhat resisted the move to design and develop throwaway designs.

Tool Design Concept

The smaller the hob diameter, the faster the rotational speed. The productivity in terms of pieces per time period is in direct proportion to the rotational speed rather than cutting speed of the tool, and in inverse proportion to the tool diameter. Opposing to the above is the need to produce a tool with a substantial number of teeth in the cut. A large number of gashes are desirable to reduce chip load per tooth and to increase the number of flats which make up the generated profile of the teeth. Obviously, the smaller the diameter of the hob becomes, the lesser the opportunity to make more gashes. This opportunity is further restricted by manufacturing methods and sharpenability. Hobs could be produced with a high number of gashes for a given diameter to achieve either maximum productivity or optimum control of the generated profile. The fundamental idea, in any case, is that we should try to reduce the hob diameter and increase the number of gashes as much as possible. This has in fact been the main change in terms of hob design over the last few years.

Emergence of Disposable Hob

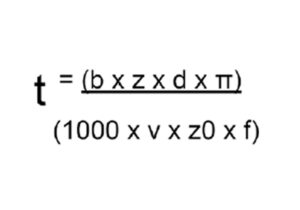

If the concept of reducing the hob’s outer diameter and increasing the number of gashes is taken to an extreme case, the result is a small-diameter hob with so many gashes that there is no sharpenable life remaining. This hob becomes a “Disposable” or “Throwaway” tool with no maintenance costs and is the basis for the disposable hob concept. The hobbing cutting time is calculated by the following equation.

This equation leads us to make some interesting considerations.

It is, however, immediately apparent that it is possible to reduce hobbing times by carrying out three different actions:

The cutting speed is something which, as stated previously, depends on many factors, but fundamentally it depends on the type of material from which the tool is made and on the type of material being worked. We have also already seen that the current limits for super alloy recoated steels are between 120 and 150 m/min. Beyond this, wear formation becomes too rapid and unpredictable, and so it becomes possible to control the operation. Having said this, therefore, it is necessary to act upon the remaining elements: the hob diameter and the feed per workpiece revolution.

It is immediately clear, however, that any adjustments that must be made to these two elements would be in contrast with one another. In fact, if the hob diameter d1 is decreased and all other conditions are unvaried, the number of gashes should also decrease. Therefore, to keep the same chip thickness, it would be necessary to reduce the feed. If were decided, however, to increase the feed per workpiece revolution there would be more gashes and therefore the hob diameter would increase. This is only true; however, if we want to obtain uniform wear distribution on the hob. If the manufacturer is willing to accept a reduction in the mechanical performance of the hob, that is if he is satisfied with an overall lower number of machined workpieces, it is a different matter.

Basically, the idea would be to reduce the diameter and to increase the number of gashes as much as possible. If this concept is taken to extremes, it would lead us to utilize disposable hobs that are hobs with a diameter of around 50 mm (or even less) and a number of gashes that are such that the hob can only be used once without resharpening. The outside diameter of around 50 mm makes it necessary to eliminate the entering bore, which means that the hob would be a solid shank type. It would therefore not be possible to utilize it on all hobbing machines, but only on those that cater for this type of tool attachment. The number of gashes may basically be from 20 to 22 allowing for a tooth of 3. – 4 mm which would be sufficient to cope with the cutting pressure.

One point against this type of hob is that it is necessary to reduce its useful length. For a diameter of 50 mm, it is not possible to have a length of more than 200 mm. Generally, a ratio of 1:4 between the diameter and the length is the maximum possible. Traditional hobs with a diameter of 90–100 mm may, on the other hand, reach lengths of up to 250 mm.

Standard disposable hob sizes are 50 mm and 65 mm diameters, with 22 mm or 32 mm pilot diameter shank styles. Using a shank-style tool allows for quick hob change, and minimizes the chance for hob mounting run out. The shank style allows for economical manufacturing as well as automatic loading and truing of the tool. The hob length is maximized for more shift positions. The disposable hob is designed to be a high-speed, productive hob.

Concept Behind Disposable Gear Shaper Cutter

A disc shaper cutter, on the other hand, changes its profile even when sharpened correctly and this will have an effect on the generated tooth profile of the workpiece to a greater or lesser degree, depending on the design of the tool. Normally, it is this change in the generated profile which determines the sharpenability of the cutter with respect to the end-of-the-life. In a resharpenable form tool, like gear tools, the side clearance is a result of the front clearance, rather than an independent feature, and usually is less than the desirable or optimum. In a circular shaper cutter, the design is even more limited. As the cutter is sharpened back, the diameter reduces according to the front clearance angle, and this change in diameter produces a change in the generated profile of the workpiece. Therefore, the tolerance on the workpiece is the first consideration and the front rake is subordinate to that. The side clearance, a critical consideration in this operation, is almost beyond the tool designer’s control, it being the result of the front clearance. In the case of a gear shaper cutter, one simple advantage is the elimination of machine setup changes related to tool change. Normally a gear shaper has to be reset for centre distance to accommodate cuter diameter change and stroke position, to accommodate cutter length change due to sharpening. Both of these changes were completely eliminated, with a corresponding increase in machine utilization. Such tools are used today for internal gears where the cutter diameter is restricted and for high helix gear cutting applications. Also, they can be used for limited production applications where the high cost of a special cutter body is not justified.

Conclusion

The cost have so far of disposable hobs is not much lower than those which been used in gear manufacturing, even though they do bring some benefits in terms of manufacturing costs:

Amongst other advantages, we could also say that this type of hob is easier to handle since it weighs less than traditional tools. This makes mounting and dismounting it on the machine easier, more accurate and quicker. One final consideration: in the event of an accident due to a machine breakdown or to a faulty workpiece, the economic damage that the breakage of a disposable hob entails is less than in the case of a traditional hob.

Some of the advantages of this concept are;

Vishwajit Kothari, CEO, Cyber Gears.

www.cybergears.in

Former Head, Sales & Marketing, Premier Ltd. He has 32 years of experience and knowledge in Machine Tools, Machining Processes, Application Engineering, Tooling and Workholding fixtures.