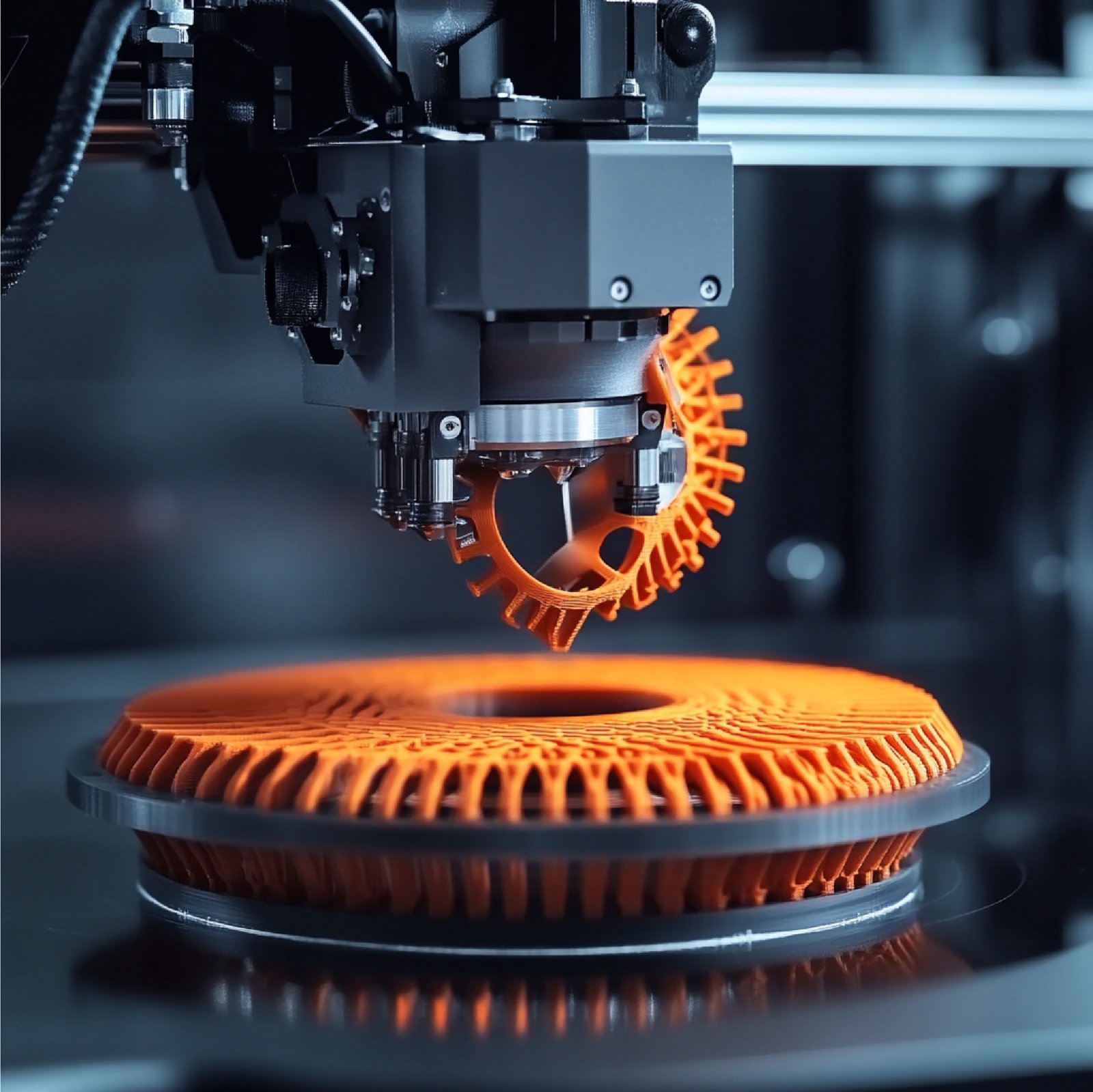

Additive manufacturing (AM), often referred to as 3D printing, has revolutionised design and manufacturing across a wide array of engineering domains. In gear manufacturing, AM technologies are providing design engineers with unprecedented freedom to create complex, lightweight, and integrated components that were previously unattainable using traditional machining methods such as hobbing, shaping, skiving, and grinding. Although large-scale production of gears via AM is still developing, the technology has matured significantly to enable functional prototypes, customised small-batch gears, and innovative solutions for repair and hybrid manufacturing.

Evolution of Additive Manufacturing Technologies

The origins of additive manufacturing can be traced back to the early 1980s with the invention of Stereolithography (SLA), which used ultraviolet light to cure photopolymer resins layer by layer. This was followed by the development of Fused Deposition Modeling (FDM), where thermoplastic filaments are extruded through a heated nozzle. These technologies laid the groundwork for layer-by-layer fabrication — the hallmark of AM.

In subsequent decades, advanced techniques such as Selective Laser Sintering (SLS), Selective Laser Melting (SLM), Electron Beam Melting (EBM), and Binder Jetting expanded AM from polymers into metals and ceramics, paving the way for manufacturing of load-bearing and precision-functional parts like gears.

Major Additive Manufacturing Processes for Gears

Powder Bed Fusion processes — including SLS, SLM, and EBM — rely on precise energy input (laser or electron beam) to fuse powdered materials. PBF allows fabrication of complex internal geometries, optimised tooth forms, and lightweight structures. Metal PBF, particularly SLM and DMLS (Direct Metal Laser Sintering), offers excellent density and mechanical strength required in load-transmitting gear applications.

In Directed Energy Deposition, powder or wire feedstock is directly melted and deposited via a laser, arc, or electron beam. Technologies such as Laser Metal Deposition (LMD) and Wire Arc Additive Manufacturing (WAAM) enable large format and repair-oriented gear applications. These are especially effective for restoring worn tooth profiles, refurbishing gearboxes, or adding material to pre-existing components.

Binder Jetting, a powder-based technique, uses a binding agent to selectively join powder layers which are later sintered. Although its as-built strength is lower than PBF, it offers good scalability and cost advantages for high-volume production of complex geometries, including prototype gears and lightweight transmission parts.

Processes such as FDM (Material Extrusion) and SLA/DLP (Vat Photopolymerization) are also used for producing polymer gears, functional prototypes, and tooling masters. These methods provide high geometrical precision and surface finish but are typically limited in strength compared to metallic alternatives. Composite-filled filaments, carbon fibre-reinforced polymers, and PEEK-based materials have extended their usability for small-scale precision drives and robotics components.

Cold Spray Additive Manufacturing represents an emerging, solid-state technique particularly suited for gearbox and rotary component production. Metallic particles are accelerated at supersonic velocities and bond plastically on impact without significant heat input. The low-temperature process avoids thermal distortion, allowing precise deposition and repair of wear-prone gear flanks or bearing surfaces. Its ability to restore dimensional accuracy and bond strength makes it a promising choice for refurbishment in aerospace and heavy-transmission systems.

Advantages of Additive Manufacturing in Gear Design

Additive manufacturing’s chief advantage lies in its design freedom. Gear engineers can now design internal cooling channels, lattice-reinforced webs, or integral housings that merge multiple parts into a single build. This approach reduces assembly complexity and enhances efficiency.

Other key benefits include:

Applications range from robotics and scientific instrumentation to automotive transmissions, aerospace mechanisms, and domestic appliances. Even tooling elements such as steel hobs have been demonstrated successfully through AM routes for small-series powertrain production.

Challenges and Limitations

Despite technological progress, several limitations continue to restrict AM gears from replacing conventionally machined gears:

Future Outlook

As research continues, emerging trends such as multi-material printing, functionally graded alloys, and AI-driven process optimisation are shaping the future of additive gear manufacturing. Integration with digital manufacturing tools like CAD/CAM simulation and automated in-process monitoring will further enhance repeatability and scalability.

Metal additive technologies—particularly PBF, DED, and Cold Spray—will likely find growing adoption in aerospace, defence, robotics, and automotive powertrains, where high-value, performance-critical gears can justify the cost and precision requirements. In the long run, the synergy between hybrid additive-subtractive systems and new alloy development will redefine the boundaries of gear engineering.

Conclusion

Additive manufacturing does not seek to replace all conventional gear production methods but to complement and extend them. Its ability to combine geometric freedom, material innovation, sustainability, and rapid design iterations marks a transformative shift in how gears are conceived and produced. As process reliability and certification frameworks mature, additively manufactured gears are poised to become integral components in the next generation of mechanical and electromechanical transmission systems.