Present-day industrial landscape is incredibly wide, and nearly every industry has a need for gears that provide increased durability, fewer failures, and better load-bearing efficiency. While the aerospace sector was historically the primary driver of demand, we are now witnessing an increase in automotive and heavy-duty industrial applications as well.

Usual high-performance gears are subjected to high stress, including surface wear, micropitting, and rolling contact fatigue, which can significantly limit their lifespan. Traditional hardening processes, including carburising and nitriding, enhance wear resistance, but they also produce tensile stresses that can cause gears to crack, particularly in high-torque and impact-heavy circumstances.

Friction Stir Processing (FSP) is a game changer for refining surface grains. It allows the development of ultra-fine microstructures with high hardness, compressive residual stress, and increased fatigue life. Unlike traditional diffusion-based hardening methods, FSP is a solid-state thermomechanical process. This means it can refine surface grains, remove porosities, and increase wear resistance without affecting the bulk material’s properties.

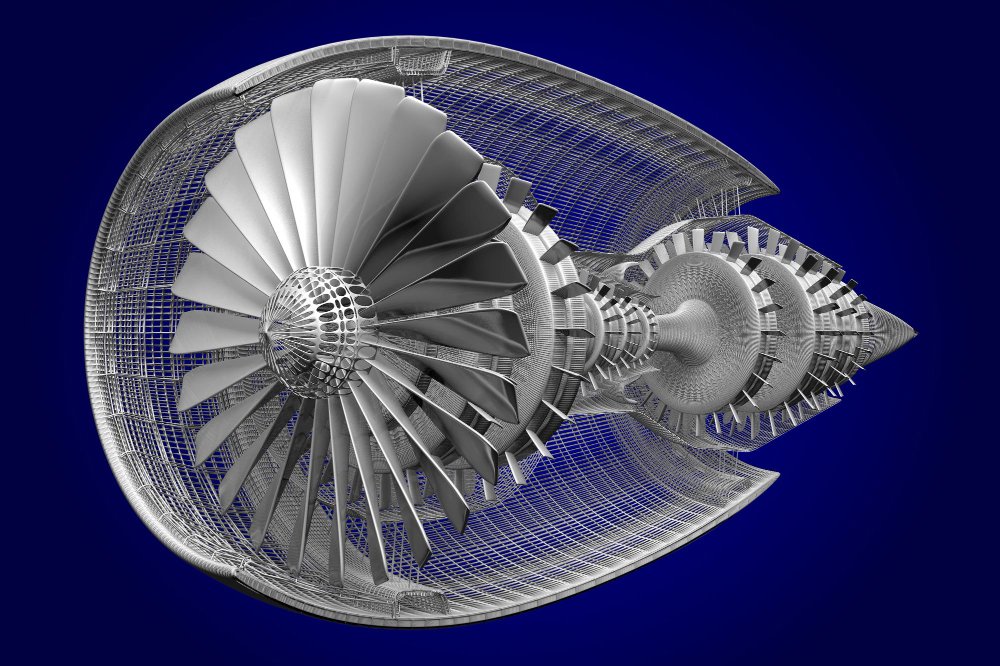

This innovative technology meets the industry’s increasing demand for gears that can handle extreme thermal, mechanical, and tribological stresses. It’s truly a transformative solution for planetary gear systems, high-speed aerospace transmissions, and critical drive mechanisms. For gear manufacturers, embracing FSP not only extends the lifespan of components but also cuts down on downtime, maintenance costs, and overall system inefficiencies—essential elements in today’s competitive, high-performance markets.

Friction Stir Processing: Mechanism and Effects on Gear Materials

Friction Stir Processing (FSP) is an interesting solid-state surface modification method. It employs a rotating tool and a non-consumable probe to produce localised severe plastic deformation. This dynamic recrystallisation process effectively alters the microstructure of gear materials, improving mechanical properties while leaving the bulk composition unchanged.

Grain Refinement: Strong shear forces and rapid strain rates break down larger grains into a super-fine structure, increasing hardness, wear resistance, and fatigue life. This is particularly critical for planetary gears and aeronautical transmissions.

Homogenised Microstructure: Friction Stir Processing (FSP) effectively eliminates segregation and refines carbide distribution, reducing material inconsistencies that can cause cracks during cyclic loading. This results in a more uniform stress distribution, which boosts the reliability of gears in high-speed and high-load situations.

Residual Compressive Stresses: This process creates beneficial compressive stresses in the surface layer, which enhances load-bearing capacity and helps delay crack initiation. This is a significant advantage compared to carburised or nitrided surfaces, which are more susceptible to failures due to tensile stress.

Oxide Dispersion Strengthening: The carefully managed thermomechanical cycle introduces finely scattered oxides, increasing thermal stability and oxidation resistance. This is critical for gears that must perform in harsh aerospace and deep-sea environments.

Performance Enhancement in High-Load Planetary Gears

Planetary gear systems face intense cyclic loads that can cause issues like micropitting, surface fatigue, and material wear. While traditional hardening methods can enhance wear resistance, they often introduce residual tensile stresses that may accelerate crack development. Enter Friction Stir Processing (FSP), a game-changing alternative that enhances the microstructure in critical load-bearing areas, significantly boosting gear durability. The ultra-fine grain structure created by FSP helps minimize crack formation and growth, thereby prolonging fatigue life even under high torque conditions. Plus, FSP offers protection for gear tooth flanks and root fillets against premature failure, making it particularly valuable in aerospace and heavy-duty industrial settings.

FSP-treated surfaces perform exceptionally well in terms of fatigue resistance. They not only have a reduced coefficient of friction, resulting in less lost energy, but they also improve gearbox efficiency. This method ensures that hardness is evenly distributed, preventing those annoying localised stress areas that can weaken gears. Unlike the standard case-hardening approach, which produces different hardness levels, FSP delivers a uniform stress profile, improving load distribution and lowering the risk of failure. For gear makers, this is a game changer in terms of performance and longevity, positioning FSP as a new technology for high-load planetary gears.

Aerospace gearbox systems require gears that can withstand tremendous torque loads, rapid temperature changes, and the challenges associated with lubrication hunger. While typical heat treatments might increase hardness, they frequently make materials more brittle, resulting in severe failures under repeated stress. Friction Stir Processing (FSP) refines the grain structure of gear materials, improving thermal and mechanical stability while preserving ductility.

This is particularly significant in high-altitude environments, where heat cycling can cause ordinary materials to degrade over time. Gears treated with FSP exhibit improved fracture resistance due to the creation of compressive residual stresses, ensuring their long-term reliability in aerospace propulsion and actuation systems.

Beyond structural benefits, FSP also enables the inclusion of oxide dispersion-strengthened surfaces with self-lubricating properties. This is a significant achievement for the space and aviation industries, where lubrication difficulties can seriously impair gear performance. FSP’s exact microstructure alterations assist reduce friction and wear, resulting in longer maintenance intervals and improved gearbox performance. For gear manufacturers, embracing FSP represents an opportunity to advance aerospace gear technology by providing performance upgrades that fit the industry’s specialised needs.

Integrating Friction Stir Processing (FSP) into gear manufacture necessitates a strategic strategy that considers material compatibility, process control, and automation potential. Unlike traditional surface treatments, FSP is a solid-state method that uses extreme plastic deformation rather than melting, making it suitable for materials such as aluminium, titanium, nickel-based superalloys, and advanced steels.

These materials gain greatly from grain refinement, higher wear resistance, and increased fatigue strength, all of which are critical for gears operating in severe conditions. However, selecting the proper material-processing combination is critical to achieving peak performance while avoiding residual stresses that might compromise gear integrity.

Process optimisation is crucial for achieving a consistent surface modification. It’s essential to carefully manage key factors like tool rotation speed, dwell time, and traverse speed to get the right microstructural refinement and hardness distribution. Today’s gear manufacturing facilities can easily incorporate Friction Stir Processing (FSP) with CNC and robotic systems, allowing for scalable production with less manual effort. By automating FSP, manufacturers can improve process consistency, cut down on defects, and maintain high-quality gears. This move towards automation is in line with the industry’s demand for advanced, high-performance gears that can handle the tough requirements of aerospace, automotive, and deep-sea applications.

Friction Stir Processing (FSP) is redefining gear durability by providing a solid-state, high-efficiency technology for surface enhancement that eliminates the disadvantages of traditional hardening processes. FSP increases the service life of gears working in harsh conditions by fine-tuning grain structures, producing residual compressive stresses, and enhancing wear resistance.

As industries seek lighter, stronger, and more fatigue-resistant components, gear makers must embrace new technology to keep up with performance and reliability expectations. Strategic investments in research and development, process optimisation, and industrial-scale adoption will be key to realising FSP’s full potential and paving the way for the next generation of high-performance gears.