Technology Outlook

The manual gear manufacturing market is a crucial component of the automotive and machinery industries, providing the fundamental mechanisms for manual transmission systems. As technology advances and preferences shift, the global market for manual gear manufacturing undergoes continual evolution. Understanding the market dynamics, trends, and forecasts is essential for stakeholders to make informed decisions. In this article, you will get insights and forecasts for the global manual gear manufacturing market spanning from 2020 to 2030.

Market Overview:

Manual gears play a vital role in various sectors, including automotive, aerospace, marine, and industrial machinery. Despite the rise of automatic transmissions, manual transmissions remain popular in certain regions and vehicle types due to their affordability, simplicity, and driver engagement. Consequently, the demand for manual gear manufacturing persists, albeit with fluctuations influenced by factors such as economic conditions, regulatory standards, and technological advancements.

As per a Transparency Market Research report, spur gears offer numerous advantages, including a wide range of transmission ratios, easy processing, and efficiency in industrial equipment. However, issues such as increased vibration, deformation, and changes in involute shape lead to undesired outcomes during the production process. This explains why the industrial gear market is projected to grow at a CAGR of 5% during the forecast period. Consequently, companies are educating end-users to utilize spur gears for bearing radial loads instead of axial loads to establish better load distribution, thereby enhancing the operational life of gearboxes.

In addition to spur gears, helical gears also come with drawbacks, such as poor axial force distribution, which often results in increased manufacturing costs. To mitigate these challenges, end-users are adopting new strategies, such as implementing the compensation effect, to enhance the durability of helical gears.

Insights and Trends:

Regional Dynamics: The manual gear manufacturing market exhibits regional variations influenced by economic growth, automotive production trends, and regulatory policies. Developing regions such as Asia-Pacific witness robust demand due to expanding automotive markets and industrialization efforts. In contrast, mature markets like Europe and North America experience stable but slower growth rates, partly due to the prevalence of automatic transmissions.

Technological Advancements: Innovation in materials, manufacturing processes, and design technologies significantly impact the manual gear manufacturing landscape. Advancements such as lightweight materials, precision machining techniques, and computer-aided design (CAD) software enhance gear performance, durability, and efficiency, meeting evolving customer expectations for reliability and fuel efficiency.

Sustainability Initiatives: Environmental concerns drive sustainability initiatives across industries, including automotive and machinery. Manual gear manufacturers increasingly adopt eco-friendly practices, such as using recyclable materials, reducing waste generation, and optimizing energy consumption in production processes. Sustainability initiatives not only align with regulatory requirements but also enhance brand reputation and appeal to environmentally conscious consumers.

Shift in Automotive Preferences: While automatic transmissions dominate in urban areas and luxury vehicles, manual transmissions remain popular in compact cars, sports cars, and off-road vehicles. However, consumer preferences are gradually shifting, influenced by factors like traffic congestion, technological advancements in automatic transmissions, and the convenience of electric vehicles. Manufacturers must adapt their product offerings and strategies to cater to evolving consumer demands.

Forecast 2020-2030:

The manual gear manufacturing market is projected to witness steady growth during the forecast period, albeit with regional variations and technological disruptions. Key forecast insights include:

Market Expansion: Despite the rise of automatic transmissions, the global manual gear manufacturing market is expected to expand, driven by sustained demand from emerging economies, niche vehicle segments, and industrial machinery applications.

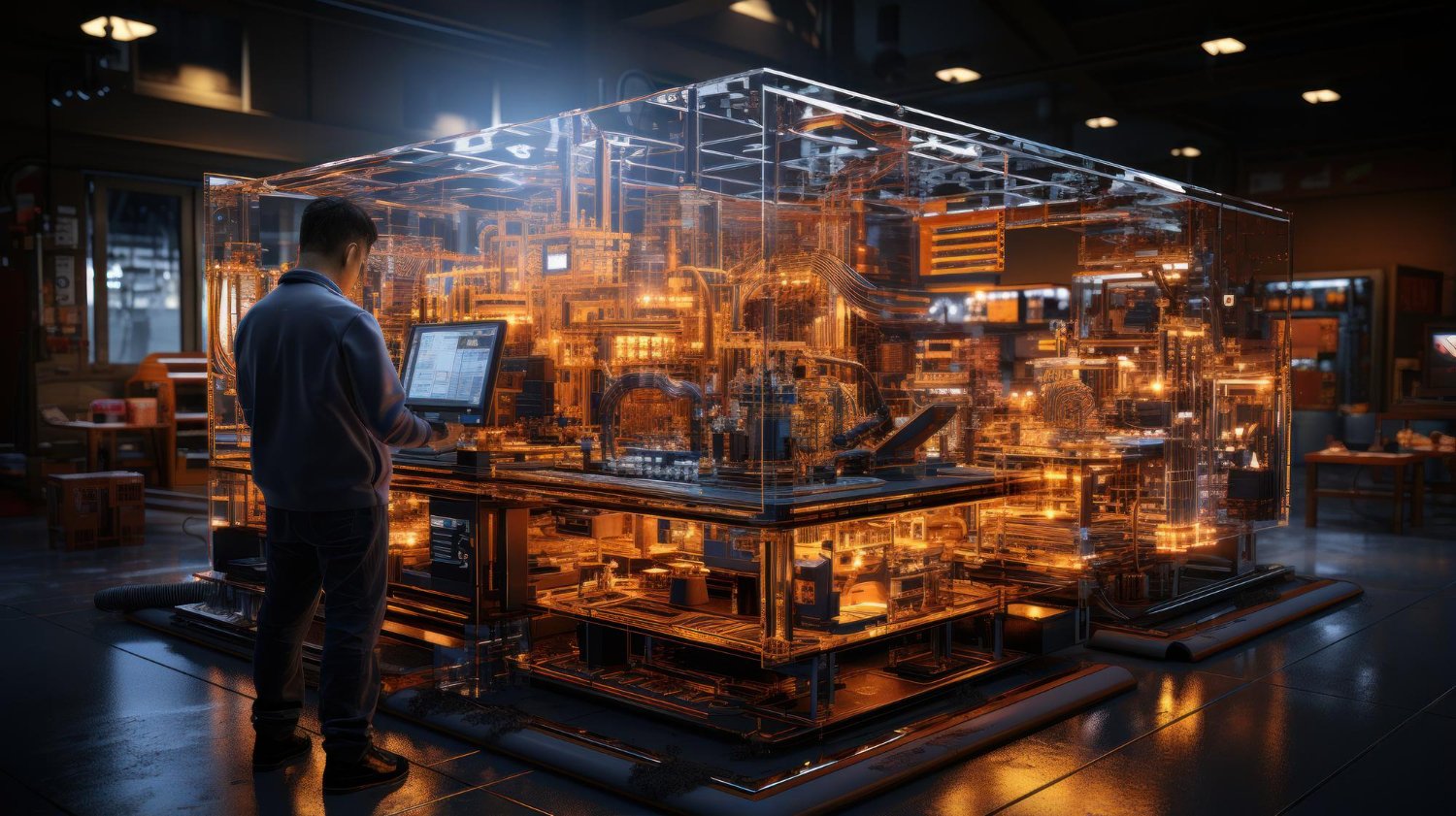

Technological Integration: The integration of advanced technologies such as robotics, automation, and digitalization will streamline manufacturing processes, improve product quality, and enhance production efficiency. Industry 4.0 principles will play a pivotal role in shaping the future of manual gear manufacturing, enabling smart factories and agile production systems.

Electric Vehicle Adoption: The increasing adoption of electric vehicles (EVs) poses both challenges and opportunities for manual gear manufacturers. While traditional manual transmissions are incompatible with electric powertrains, specialized gear systems for hybrid and plug-in hybrid vehicles may emerge as a niche market segment.

Regulatory Landscape: Stringent emissions regulations and fuel efficiency standards will drive innovation in manual gear manufacturing, prompting manufacturers to develop more efficient gear designs and lightweight materials to reduce energy losses and enhance vehicle performance.

Way Ahead

The manual gear manufacturing sector serves as a fundamental component of the automotive and machinery industries, supplying the necessary components for manual transmission systems. As our comprehension of this sector deepens, it becomes apparent that its trajectory is intertwined with technological advancements, changing consumer preferences, and regulatory frameworks.

Despite the dominance of automatic transmissions, manual gear manufacturing remains pertinent, driven by factors like cost-effectiveness, simplicity, and driver involvement. This enduring relevance is accentuated by the continual progress in gear technologies, with innovations such as helical gears and strategies like the compensation effect addressing inherent issues such as vibration and distortion.

Looking forward, the manual gear manufacturing industry is positioned for consistent growth, fuelled by increasing demand from emerging markets, specialized vehicle sectors, and industrial applications. However, this growth path comes with its own set of challenges. The integration of technology, particularly the embrace of Industry 4.0 principles, will transform manufacturing processes, ushering in an era of intelligent factories and flexible production systems.

Additionally, the emergence of electric vehicles presents both obstacles and opportunities. While traditional manual transmissions may face obsolescence, there exists a demand for specialized gear systems in hybrid and plug-in hybrid vehicles, potentially creating a niche market segment. Adapting to strict emissions regulations and fuel efficiency standards will further stimulate innovation, driving the advancement of more effective gear designs and lightweight materials.

By staying abreast of market dynamics, embracing technological progress, and promoting sustainability efforts, stakeholders can navigate this evolving landscape and seize emerging prospects.