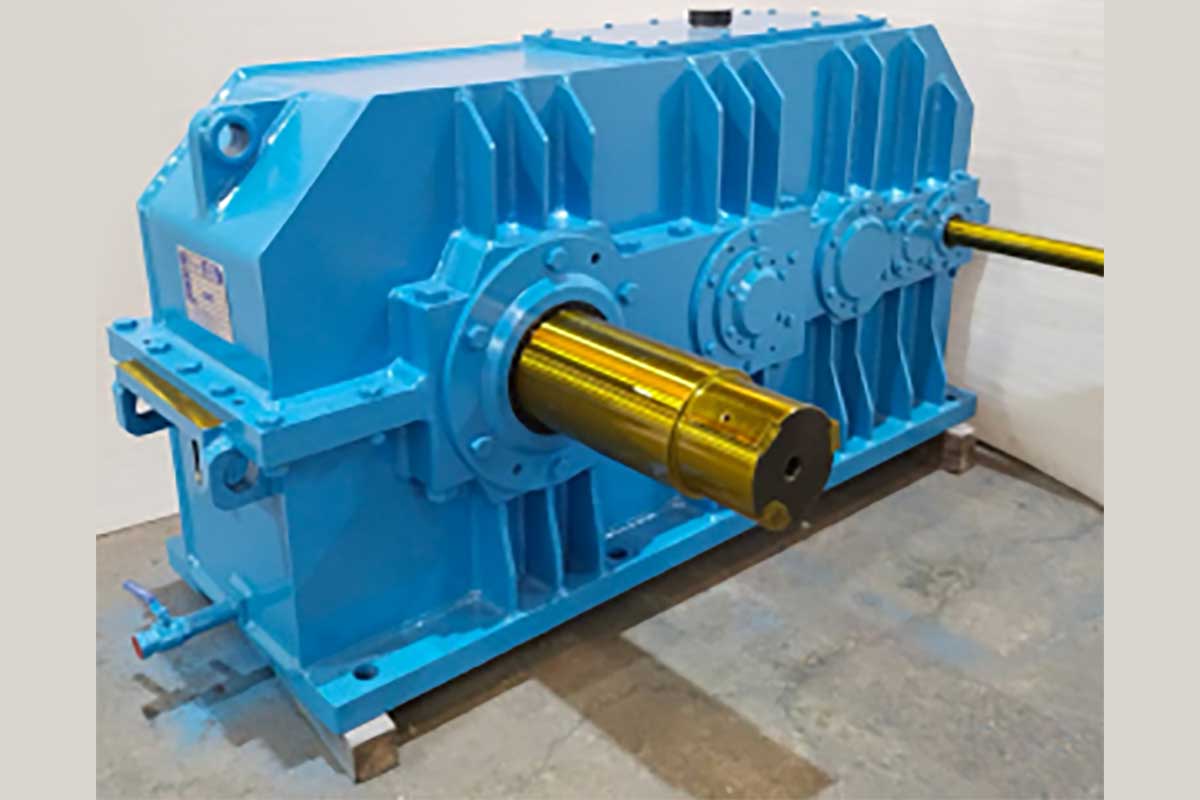

Helical gearbox

Please tell us a little about your company and its expertise.

Please tell us a little about your company and its expertise.

ESENPRO, a brand of ESENPRO Power Transmission Pvt. Ltd., is one of the leading manufacturers and exporters of high quality industrial gearboxes.

We are in the business of designing, manufacturing and servicing all types of industrial gearboxes, and offer our products both in standard and customized categories.

ESENPRO executes re-engineering of existing / old gears and gearboxes for any plant and machinery, to enhance their capacity, withstand higher speed, feed, and load, within the existing mounting dimensions.

ESENPRO designs and supplies drop-in replacement gearboxes. These gearboxes replace the old gearbox exactly, without an inch of modification to the existing foundation.

In addition to the existing range of products, ESENPRO has an independent engineering team to develop planetary gearboxes for steel, power, sugar, material handling and mining.

Helical gearbox

ESENPRO is equipped with complete in-house designing, machining, gear grinding, metrology, calibration, and assembly and testing facilities. The ESENPRO gearbox range includes helical gearboxes, bevel helical gearboxes, worm gearboxes, crane duty gearboxes, cooling tower gearboxes, extruder gearboxes, rolling mill gearboxes, and aerator gears and special gearboxes for crane, power, steel, paper, and mining industries. We also manufacture open gears as per customer design.

Helical gearbox

ESENPRO is a trusted brand for customized gearbox solutions. With our expert design and engineering team we are developing industrial gearboxes for high power and high torque demands.

Our latest product development includes:

1. Upgrading Cross Travel Drive for 500T Molten Metal Handling Crane

2. Helical – Planetary Hoist Gearbox for Mine Winders

3. Primary Gearbox for Rubber Calendar Machine

4. Integrated Drive System for Belt Conveyor

Bevel Planetary Gearbox

ESENPRO brings an innovative solution for customized gearbox requirements. We design one-to-one replacement of the customer’s existing gearbox. We ensure to maintain the performance and quality standards of the same. Enhancement of power ratings of the gearbox within the same footprints of the existing gearbox is provided too. Drop-in replacements are produced for all types of industrial helical, bevel, helical and planetary gearboxes for steel, cement, plastic, rubber, mining, power, cranes, chemical and sugar industry of any brand.

Custom Design Helical Gearbox

We believe that reducing unnecessary energy inefficiencies is an important step to minimizing the carbon footprint. Switching off lights and computers when they’re not required, and finding out which machines need to be on standby and which can be switched off, using transport plans logistically, minimizing water waste, ensuring proper disposal of waste generated by various grinding machines – these are areas of concentration to reduce our carbon footprint.

Helical gearbox

GTI can provide real cases wherein any gear manufacturing industry has experienced an increase in efficiency, reduced noise level etc,. by virtue of having introduced any advanced technology. Articles on gear failures, heat treatment and current industry demands too will help disseminate knowledge.