By: Nishant Kashyap

Hybrid gear manufacturing involves using a combination of different manufacturing processes and techniques to produce gears. This can include a mix of traditional methods like hobbing, milling, or grinding, along with newer technologies such as additive manufacturing or 3D printing. The goal is to leverage the strengths of each method to optimize the production process and achieve desired gear characteristics.

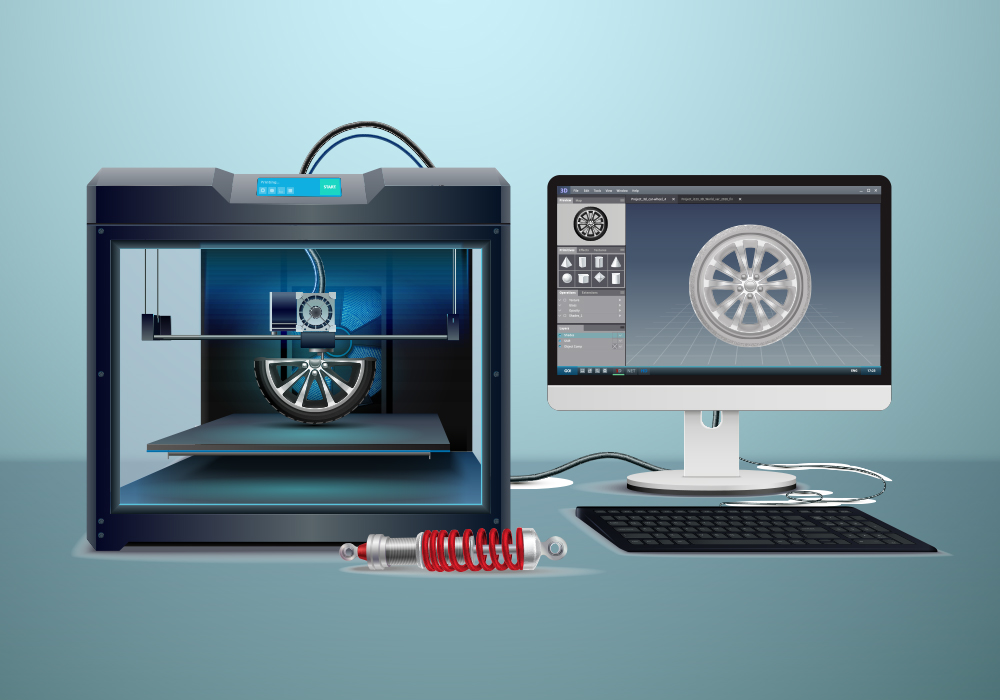

For example, additive manufacturing can be used to create complex gear geometries with high precision, while subtractive machining processes may be employed for finishing and improving surface quality. The hybrid approach allows manufacturers to take advantage of the versatility and efficiency of various techniques to produce gears that meet specific requirements. This approach leverages the strengths of both AM and SM to overcome the limitations of traditional gear manufacturing methods.

Additive manufacturing, also known as 3D printing, allows for the creation of complex geometries and intricate structures that are difficult or impossible to achieve through conventional machining techniques. This capability is particularly beneficial for gear teeth, which require precise and highly defined profiles. AM can also enable the utilisation of lightweight and exotic materials that offer superior strength, wear resistance, and corrosion resistance. Subtractive manufacturing, on the other hand, excels in refining the surface finish, dimensional accuracy, and overall precision of the fabricated gears. It can also remove excess material from complex geometries, improving the accessibility of gear teeth for lubrication and ensuring smooth operation.

Design considerations for Hybrid Gears:

The design of gears in hybrid gear manufacturing is a complex process that requires careful consideration of several factors, including the application, geometry, material selection, and manufacturing processes. The goal of hybrid gear design is to create gears that are both strong and lightweight, with good wear resistance and fatigue life.

Quality Control and Inspection in Hybrid Gear Manufacturing:

In hybrid gear manufacturing, a strict approach to quality control and inspection is important to ensure the precision and reliability of the final products. The process begins with a thorough design validation, ensuring adherence to specified tolerances and requirements. The inspection of raw materials is crucial, encompassing tests for material composition, hardness, and other pertinent properties in both traditional and additive manufacturing processes. Traditional manufacturing undergoes scrutiny through methods such as coordinate measuring machines (CMM) to verify accuracy and precision, while additive manufacturing components are subject to advanced inspection tools like 3D scanners or computed tomography (CT) scans to assess both internal and external geometry. Special attention is given to integrated features such as cooling channels or sensor mounts, confirming their correct implementation.

Surface finish inspections employ tools like surface profilometers, ensuring adherence to specific roughness parameters. The assembly phase undergoes verification to ensure seamless integration of components manufactured through different processes. Non-destructive testing (NDT) methods detect internal defects, while comprehensive documentation of quality control processes and in-process monitoring contributes to traceability and continuous improvement. Statistical process control (SPC) methods are employed to monitor variations, and a feedback loop between quality control and the design phase facilitates continuous refinement. This union of traditional and advanced inspection techniques ensures that the hybrid gear manufacturing process results in products that meet rigid quality standards, characterised by reliability and optimal performance.

Emerging technologies in hybrid gear manufacturing:

The landscape of hybrid gear manufacturing has seen noteworthy advancements and research directions, with several emerging technologies shaping the industry. Additive manufacturing has witnessed ongoing progress, marked by improvements in speed, precision, and the expanding collection of materials suitable for 3D printing gears. Of particular interest is the evolution of multi-material 3D printing, enabling the creation of hybrid gears with distinct material properties in different sections, enhancing overall performance and functionality.

Another notable trend involves the integration of in-site monitoring and control systems during additive manufacturing processes, ensuring real-time quality control and defect detection. The convergence of machine learning and artificial intelligence in the field has led to the optimization of gear designs based on performance data, paving the way for more efficient and customised solutions. Digital twins and simulation technologies have gained prominence, allowing for accurate modelling of the behaviour of hybrid gears, thereby facilitating predictive maintenance and performance optimization.

Additionally, nanotechnology is being explored for developing advanced materials with superior mechanical properties, wear resistance, and durability. The research focus extends to hybrid manufacturing processes that seamlessly combine additive and subtractive methods in a single system, promising versatility and efficiency.

Sustainability in hybrid gear manufacturing is a growing concern, leading to research endeavours aimed at reducing energy consumption, minimising waste, and exploring eco-friendly materials. Innovations in advanced surface treatments and coatings are also underway to enhance wear resistance, lubrication properties, and overall longevity of hybrid gears. The integration of collaborative robotics in manufacturing processes, particularly in the assembly of hybrid gear components, is gaining traction.

Furthermore, there is ongoing research into leveraging blockchain technology for enhanced supply chain transparency, ensuring traceability and quality control throughout the production process. The broader integration of smart manufacturing principles and Industry 4.0 technologies, such as IoT devices and connectivity, is indicative of a paradigm shift toward real-time data monitoring, analysis, and optimization in hybrid gear manufacturing. It’s important to note that the field is dynamic, and continuous monitoring of the latest literature, industry publications, and conferences is essential to stay informed about the most recent developments in emerging technologies for hybrid gear manufacturing.

In recent years, significant strides have been made in the development of hybrid gear manufacturing through the integration of additive manufacturing (AM) and subtractive manufacturing (SM) processes. Novel techniques are emerging to seamlessly blend the design flexibility offered by AM with the precision of SM, creating gears that embody the best attributes of both worlds. This integration aims to optimize the production of gears by leveraging the intricate geometries achievable through AM and the accuracy afforded by SM. Concurrently, the manufacturing landscape is witnessing the advent of advanced hybrid machines specifically designed to amalgamate AM and SM processes within a single platform. This innovation not only simplifies the manufacturing process but also holds the potential to reduce costs, enhance efficiency, and streamline production workflows.

Additionally, the development of cutting-edge simulation tools is playing a pivotal role in predicting the performance of AM-SM gears. These tools aid in reducing the need for extensive prototyping, allowing for more accurate assessments of the final product’s quality. The ongoing research and development in these areas underscore a commitment to advancing the capabilities of hybrid gear manufacturing, promising more efficient, cost-effective, and high-quality production processes in the future.