Blaser Swisslube’s Liquid Tool helps Improve Productivity and Reduce Cycle Times

Author Gear Technology India on June 16, 2023

Blaser Swisslube helps manufacturers fully capitalize on the potential of their machines and tools and turn the metalworking fluid into a key success factor – a Liquid Tool

History

Headquartered in Hasle-Rüegsau, Switzerland, with production facilities in Switzerland and America, the family-owned Swiss company develops, produces and sells a comprehensive range of metalworking fluids of the highest quality, performance and reliability for a variety of industries.

Global CEO Marc Blaser, who represents the third generation of the family-owned business, believes that manufacturers can fully capitalize on the potential of their machines and tools and turn the metalworking fluid into a key success factor — a Liquid Tool — that can improve productivity for customers and help them succeed.

In India, the Blaser Swisslube subsidiary began in 2001. Under the leadership of Mr. Punit Gupta, it is contributing to its customer’s productivity, economic efficiency and machining quality. In terms of new gear hobbing and grinding technologies, Blaser Swisslube offers solutions to its customers and addresses their challenges for improved efficiency, increased tool life, and reduced cycle times. These can be accomplished with higher parameters, which cause higher machining temperatures.

“We aim to improve these points in cooperation with our customers,” Punit Gupta, Managing Director West Asia at Blaser Swisslube says. “As higher parameters produce more heat in the machine, we have to find the optimal cutting fluids. With our product range of cutting fluids, we want to deliver an added value where higher cutting parameters in combination with lowest risk of smoke formation are achievable.

The focus to reduce smoke production is a need in the area of environmental health which the top management needs to focus on”, he adds.

Range of Metalworking Fluids and Its Applications in Various Industries

Our focus is to work on all the materials and applications within machining & grinding operations. We offer our customers water miscible coolants, neat oils & MQL (Minimal Quantity Lubrication) range for different segments and applications. These products are built on various technology platforms like a unique bio concept, zero germ principal, ester based and fully synthetic.

Neat oils offer high success in gear cutting, gear grinding, broaching, tool grinding, gun drilling applications etc. Materials like steel, cast iron & aluminium in the automotive industry to materials like Titanium, Inconel, SS etc are very interesting to look at for increasing productivity and machining performance.

MQL has been a niche area in industry so far, however, we are geared for the same with many happy customers.

All these areas have a potential to offer up to 20-40% increase in tool life and/or 8-15% increase in productivity as per various projects records. However, we always analyse the process of the customer and then make a proposal.

Case Study about Productivity Increase in Gear Technology

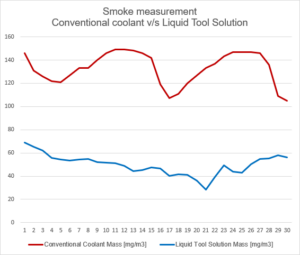

Recently, Blaser Swisslube India was able to help increase the productivity of a customer in the field of Gear Technology. The goal was to reduce the cut time of forged steel components and lower smoke and mist in the facility.

The Blaser Sales Engineer, in close collaboration with the customer, switched during a test phase a conventional cutting fluid to a Blaser ester oil-based cutting oil and increased the cutting speed by 20% with convincing results. The cut time was reduced by 24%, the advent of smoke and mist was reduced by 51% and lowered the overall costs per component. Gupta says “Many applications have a potential to increase up to 20-40% in tool life and/ or 8-15% in improved productivity as per various projects records. We at Blaser always analyse the process in the beginning and then make a proposal to the customer of what he can improve in the long run.”

Service Support for Customers

We have an experienced and trained team of technical salespeople, application engineers to help customers onsite. Blaser Swisslube is renowned for its personal on-site support. If we’re not on site, we’re still there for you with our Remote Care Tool. With Blaser Remote Care, we can support our customers quickly and completely from a distance — live via video — and also due to our “augmented reality.” We can discuss and solve issues quickly and effectively via mobile phone or tablet.

All customers need is access to the Internet without installing any app or software. This increases productivity and customer satisfaction, as we save time and travel costs and customers quickly receive the support they need. We continuously invest in know-how and facilities — in India and globally. The recent investment in the Country Competence Centre in India (named CCC) is an example of the future oriented journey of the coolant company. The CCC gives Blaser customers an opportunity to monitor their critical coolant parameters. The CCC is equipped with state-of-the-art laboratory equipment. It is also open for customers and partners for visits and training.

Collaboration between your research team and manufacturing expertise in creating metalworking fluid

At our Research and Development facilities in Switzerland, we have the opportunity to test the latest metalworking fluids and recreate the versatile machining operations of our customers and partners in a realistic way. At present, research is carried out using four CNC milling machines and a state-of-the-art grinding machine. The latest high-precision measuring devices and sensors enable the data acquired to be interpreted correctly. So, at this in-house facility, our laboratory research team works hand in hand with our manufacturing experts to ensure that our latest metalworking fluids meet the expectations in the customer production halls. For this purpose, we have set-up various performance tests in our technology centre. It’s only when a new development has cleared all hurdles, it is ready for the market.

Training Programs for Customers

We are fully committed to provide customers with comprehensive solutions rather than merely products. It triggers the role of a good maintenance & monitoring system onsite by customers. We also help customers by imparting the know-how and training to their people.

New Product Launches

Our product portfolio is reviewed and adjusted every year. While developing new formulations, we always keep our customers’ needs in the centre. We receive consistent feedback from the customers in the market, so that the right solution can be given to our customers.

We have new oil Blasogrind GTS 15 for gear grinding application which is especially formulated to reduce burn marks and increase feed rate thereby higher productivity. The increased lubricity allows faster metal removal rates while avoiding grinder burn, reduced scrap rate due to decreased risk of grinder burn. This high-performance grinding oil is optimised for high feed rates, long dressing intervals and excellent surface quality.

How will Gear Technology India help the industry?

It is good that Gear Technology India has been launched in India. There is a lot of development happening in the gear industry and Gear Technology India can serve as a platform for the distribution of knowledge related to gear technology. This can help professionals and companies stay updated with the latest developments.

Punit Gupta, Managing Director, West Asia at Blaser Swisslube

Post Views: 547