Poll Results Analysis

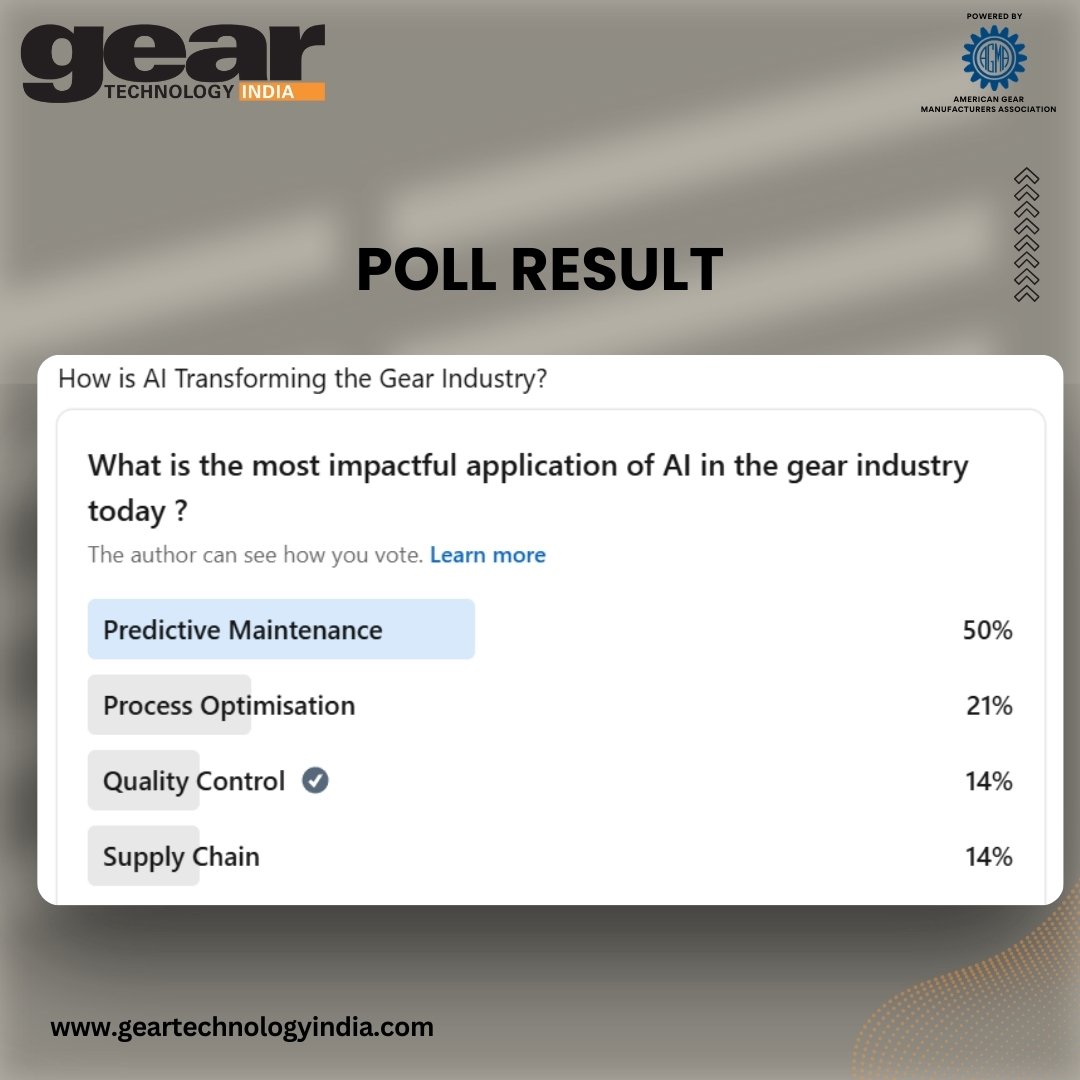

Recently we conducted a poll on the role of AI in the Gear industry

The poll results highlight that Predictive Maintenance is currently viewed as the most impactful application of AI in the gear industry, garnering 50% of the votes.

This overwhelming preference signifies the industry’s prioritisation of minimising downtime, reducing unexpected failures, and optimising equipment performance. AI-driven predictive maintenance solutions leverage advanced algorithms and real-time data to anticipate potential issues, leading to significant cost savings and improved operational efficiency.

Process Optimisation received 21% of the votes, indicating its importance in streamlining production workflows and enhancing throughput. AI applications in this area focus on reducing cycle times, energy consumption, and material waste, contributing to more sustainable and efficient manufacturing processes.

Quality Control and Supply Chain tied at 14%, signalling that these areas are also recognised as crucial for leveraging AI. In quality control, AI enhances precision through automated defect detection and process consistency. Meanwhile, AI-powered supply chain management improves demand forecasting, inventory planning, and logistics, ensuring smoother operations.

This poll identifies the diverse ways AI is shaping the gear industry, with predictive maintenance leading the charge, but with significant opportunities for growth in other domains like process optimisation and supply chain integration.

These insights can guide industry stakeholders in prioritising their AI investments and strategies shortly.