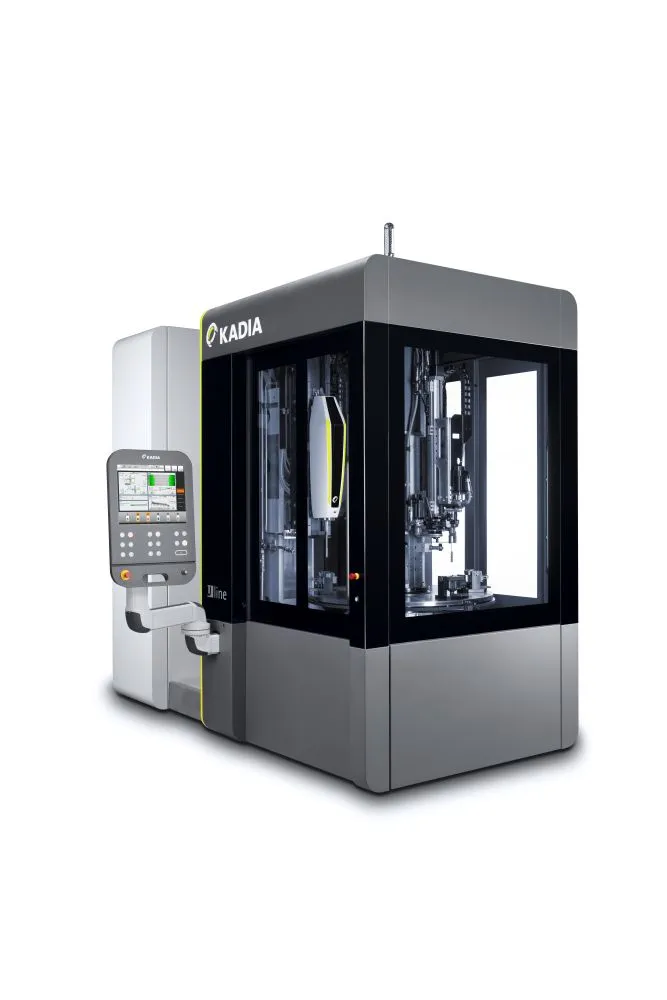

With the third generation of its successful U line, Kadia introduces a state-of-the-art honing machine that redefines standards in precision, productivity and serviceability–while maintaining full versatility.

“The U line combines what has always been at the core of Kadia: ultimate machining accuracy and maximum cost-efficiency through short cycle times, high machine availability and outstanding process reliability,” explains Henning Klein, managing director of Kadia.

The U line is designed as a compact rotary indexing machine with six stations: two honing stations for rough and finish honing, two measuring stations, a loading/unloading station and an optional integrated brush-deburring station. Key maintenance components such as pumps, pneumatic systems and lubrication units are centralised and easily accessible in a dedicated service compartment.

Based on the experience gained from over 50 delivered systems from previous U-line generations, the new machine lives up to its name – the “U” stands for “Universal.” It covers a wide machining range from 1.5 mm to 40 mm bore diameters, making it ideal for both small parts like gears and larger components such as those used in the hydraulics sector.

A standout feature of the new U line is its significantly enlarged working area. The diameter of the rotary table has been increased by 30 percent, resulting in 60 percent more table surface, enabling the use of larger fixtures and significantly expanding the machine’s application range. A smart feature: the transport speed of the rotary table automatically adjusts to the workpiece weight, minimizing mechanical wear and extending the drive’s service life.

While the machine’s footprint remains a compact 4.5 m², its mass has been increased by 20 percent, improving vibration damping. This allows the new highly dynamic honing spindles to operate more effectively–a key factor in reducing cycle times and maintaining process stability even at high material removal volumes.

User comfort and fast changeovers were top priorities in the development of the new U line. A walk-in side niche allows rear access to the work area for the first time–ideal for quick gauge changes at the rear measuring station. The front-loading door has been widened by 10 percent, improving manual part loading and enhancing overall workstation ergonomics.

“Today, our customers expect not only precision machines but also smart operating concepts that directly contribute to overall equipment effectiveness,” emphasizes Klein. “With the new U line, we significantly reduce setup times and boost machine availability.”

At the heart of the new U line is the newly developed LH2x honing spindle–the next evolutionary step in the successful “Lean Highspeed” series. Featuring three integrated direct drives for oscillation, rotation and tool expansion, the spindle introduces a completely new concept. It delivers higher cutting speeds, broader versatility, and easier maintenance compared to its predecessor. Four new patents underline the innovative strength of this development.

Together with the LH2x spindle, the HMC100 control unit forms the technological backbone of the U line. It enables scanning of the honed bore in the axial direction, significantly improving in-process measurement quality. Even complex geometries can be analyzed precisely and consistently–a major advantage for high-end, reliable honing processes.The HMC100 also supports multi-stage honing within a single cycle, with each stage individually programmable, e.g., in terms of cutting speed. This improves both cycle time and bore quality. A new feature, Form Honing, allows precise machining of tapered or barrel-shaped bores.

The measuring stations have also been technologically refined. Thanks to a rotary drive, workpieces can be inserted in any orientation, while the measuring axis automatically detects the correct position. The new measuring axis design also allows the use of shorter probes, enabling faster and more precise measurement, reducing cycle time and enhancing quality.

In the deburring unit, a new motor with 40 percent higher rotational speed significantly improves performance, especially for small-diameter bores. The automatic brush changer has been redesigned for higher robustness and now features new magazines that hold up to eleven spare brushes per diameter. This further automates the deburring process and minimizes downtime.

Whether for mixed-model production or high-volume manufacturing, manual or automated loading, the U line is the universal honing machine for the highest quality and maximum productivity in bore finishing.

The new U line brings together over a decade of U line expertise with Kadia’s decades-long honing expertise and enhances it with innovative technical advancements. It is a well-conceived, high-performance solution for manufacturers who demand precision, flexibility, and peak economic efficiency.