In the realm of manufacturing, the International Society of Automation highlights a critical issue: factories often experience a loss of manufacturing capacity due to downtime, ranging from 5% to 20%.

Traditional preventive maintenance processes, which involve repairing machines at fixed intervals based on time or usage, still result in significant equipment failures.

These failures lead to idle workers, increased scrap rates, lost revenues, and disgruntled customers. Moreover, preventive maintenance sometimes replaces parts that still have a considerable working life, resulting in wasted time and money.

AI-based predictive maintenance offers a smarter approach. It leverages data from various sources, including IoT sensors embedded in equipment, manufacturing operations data, and environmental data.

By analysing this wealth of information, AI models can identify patterns that indicate failure modes for specific components. They can also generate more accurate predictions of component lifespan based on environmental conditions.

When specific failure signals are detected or component ageing criteria are met, the components can be replaced during scheduled maintenance windows.

But that’s not all. Traditional manufacturing processes often involve significant investment in prototyping and destructive testing to find safe and cost-effective assembly solutions. While this development process is essential to ensure that a design meets client specifications, it can be expensive in terms of wasted materials and time for designers and engineers.

By analysing a wide range of data—materials properties, prior configurations, test results, and more—AI can uncover patterns that lead to optimal manufacturing solutions.

It’s like having a keen-eyed detective searching for clues in the manufacturing data landscape.

The result? More efficient processes, better designs, and ultimately, satisfied clients.

So, whether it’s predicting maintenance needs or optimizing assembly methods, AI is transforming the manufacturing industry, one data point at a time.

Enhancing Organizational Efficiency:

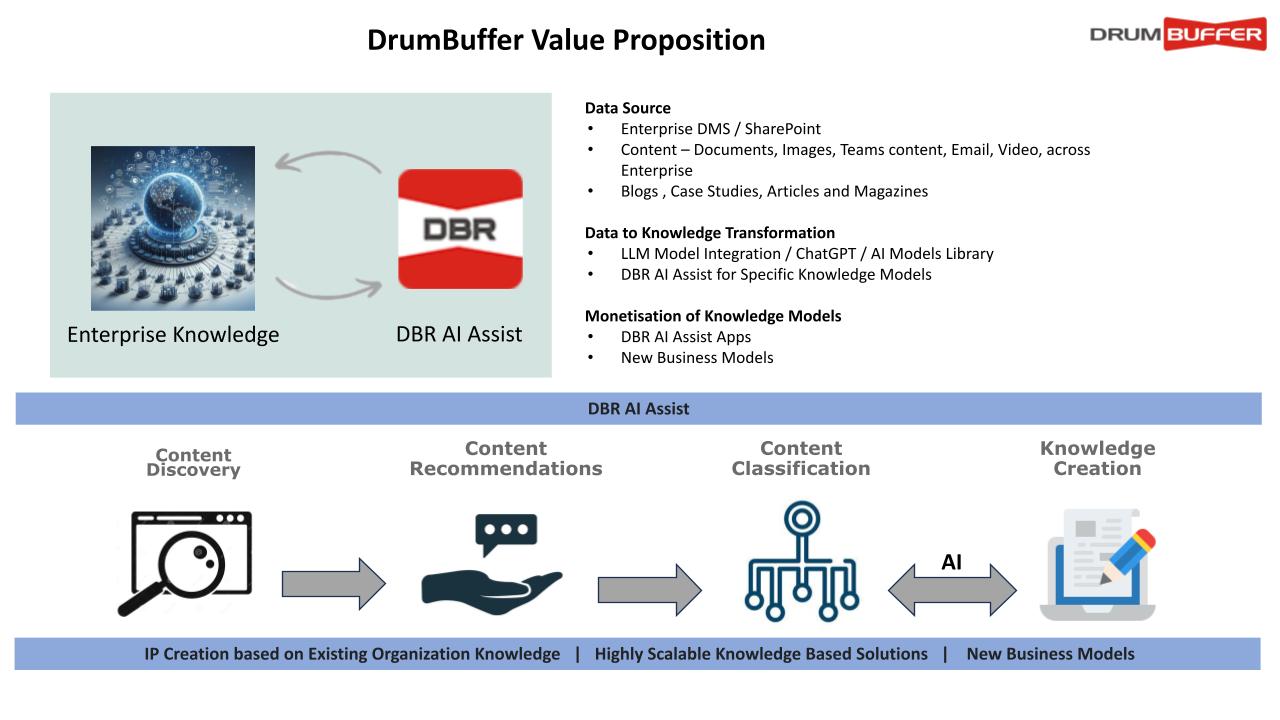

Knowledge management is a critical aspect of any organization’s survival. It involves structuring, collecting, and sharing knowledge within the company. As companies evolve and expand, they accumulate significant knowledge.

Generative AI, holds immense potential for transforming knowledge management practices in the 21st century, benefiting organizations across various industries.

Improved Information Access:

DBR AI Assist can seamlessly integrate into knowledge management systems. Its AI-powered capabilities efficiently retrieve information, resources, and documents.

Employees no longer need to manually search for papers; they can access up-to-date information with just a few prompts.

This streamlined process saves valuable time and enhances overall productivity.

Enhanced Knowledge Sharing and Collaboration

Continuous learning and collaboration across departments become possible.

Increased Employee Experience. Employees can access knowledge promptly without facing unnecessary hurdles.

The user-friendly interface streamlines information retrieval, enhancing workplace satisfaction.

Self-Service Support. It reduces information barriers for customers and provides efficient solutions to issues.

Incorporating DBR AI Assist into knowledge management can revolutionize how organizations operate, fostering efficiency and growth.

Use Cases:

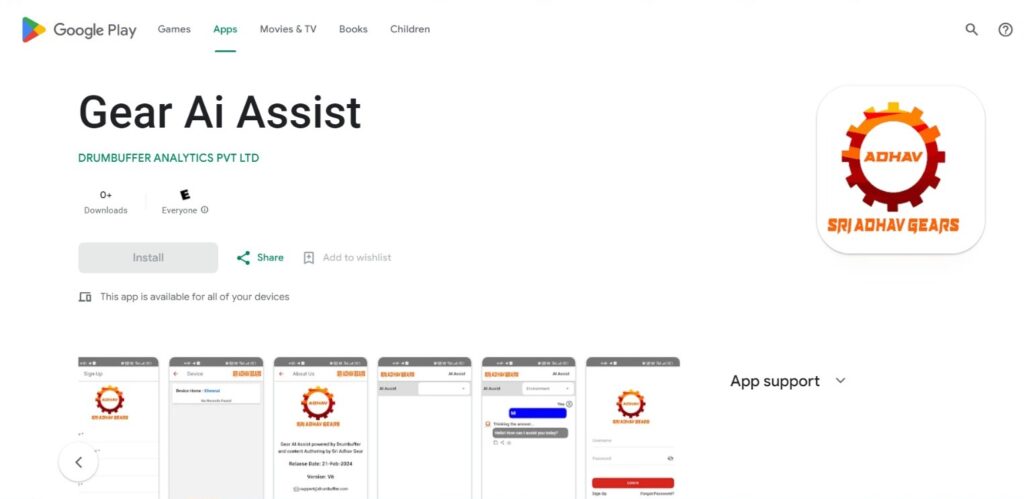

Troubleshoot for Maintenance

Gear Box Maintenance Assist

Gear Box Selection Assist

Gear Box comparison across various Brands

Conclusion

The DrumBuffer AI Assist App represents a significant advancement in manufacturing efficiency and effectiveness. By leveraging AI-based predictive maintenance, it addresses the critical issue of downtime in factories, leading to increased capacity and productivity.

Additionally, AI-driven analysis optimizes assembly methods, reducing costs and improving design outcomes.

Moreover, the integration of AI into knowledge management systems enhances organizational efficiency by facilitating seamless access to information and promoting collaboration. As AI continues to evolve, its transformative impact on the manufacturing industry promises to revolutionize operations and drive sustainable growth.

The Author

Arun Annamalai

CTO

Drumbuffer Analytics

Private Limited