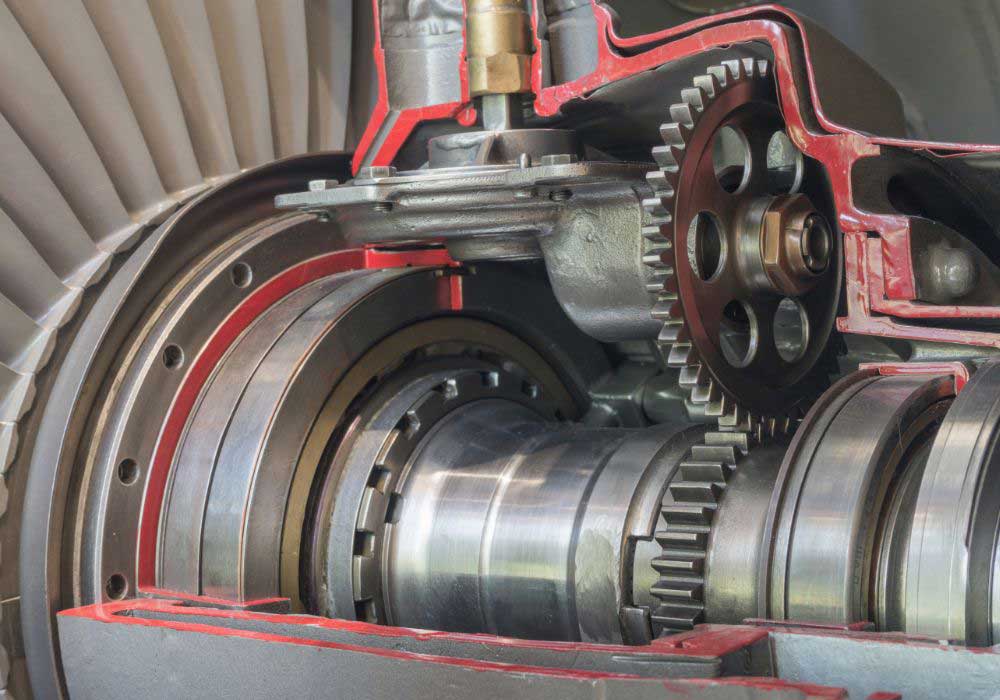

In a gearbox, the airborne noise is generated due to churning of air because of the rotating elements between the gear wheel and casing

By: Commander Srikanth

In many industrial environments, low frequency noise may occur in combination with vibrations.

High frequency noise is generally associated with high-speed machinery related noise because of pressure difference in various engineering elements related to flow parameters. While annoyance due to airborne noise has been found to be greater in combination with vibrations. Unfortunately, there is little information available about the combined effects of low frequency noise and vibration.

Furthermore, it can be expected that subjects confuse the exposures and thus have difficulty in differentiating between the sensation of vibration and noise. Present data indicate that a combined exposure would increase annoyance. Apart from sound emissions from vibrating building elements, secondary phenomena may occur in the form of rattling doors, clattering vessels, tea cups, plates (crockery), and glass panes. These phenomena are reported to significantly increase the annoyance and have typically been reported in more lightweight items with regard to aircraft take off, heavy artillery, and at a distance from highway bridges and high-speed trains.

In a gearbox, the airborne noise is generated due to churning of air due to rotating elements between gear wheel and casing. In some cases, due to spraying of lubricating oil, gear engagement and disengagement of various gear tooth and very minor bending due to these cyclic loads. Thin gear tooth at times exhibits a tunning fork-like phenomenon. In some instances, the support bearings and their condition, balancing and unbalancing also contribute to structural noise that are perceived as vibrations at the foot or pedestal of the gearbox. In certain cases, optimised casing thickness can also lead to vibration of casing elements made of fabricated thin sheets. This is termed as loudspeaker effect.

Airborne Noise

Typically, the airborne noise emits from:

Structure vibrations:

Also known as impact noise which in turn excite the

surrounding medium resulting in audible sound. This happens when an element is stretched, held taut, and a small disturbance leads to vibrations. Examples include tuning fork, musical stringed instruments, percussion instruments and so on. In fact, a loudspeaker is one of the best examples which can be linked to a thin wall gear box fabricated casings having ribs as structural stiffeners. Between the ribs, the thin sheet metal acts as a diaphragm of a loudspeaker.

The same occurs on board ship also as the large area of plate is welded and is tightly held between frames with relatively low mass vis-à-vis that of support structures.

Therefore, any vibrations transmitted to ship’s structural plates induces a loudspeaker effect and the water density being higher, the speed of sound in water is 1500 m/s as against speed of sound in air 340-350 m/s. Thus, even a small impact noise is quickly and efficiently carried to a long distance three times faster than in air.

Pressure difference:

In any flow, the changes in flow pressure induces noise. The wind instruments is a classic example. Similarly, in IC engines the difference in atmospheric pressure and exhaust gas pressure which is made to expand to atmospheric pressure suddenly. Therefore, a muffler as the name suggests, muffles noise by gradual expansion in other words controlled reduction of pressure of gases. Similarly, whirling of fluids due to a rotating part of a mechanical equipment induces noise due to pressure difference across the path.

It is well known from the conservation principle of energy; higher speeds cause lower pressures and thus the pressure difference increases with that of the ambient. In gas turbines/ jet engines high pressure/high energy gases go through a thrust tube/jet tube which is suddenly exposed to atmospheric pressure. The high-speed high-volume exhaust thus causes very intense and high frequency sound. Similarly, flow through pipes wherever the pipe fittings and change of direction occurs results in pressure difference and this becomes the source of audible noise.

The same is true in a gearbox where each mating tooth deforms and regains its shape and is related to the speed of the gears / gear tooth engagement frequency. This again causes structural deformation of tooth which excites the surrounding medium and passes out as airborne noise transmitted from the gearbox casing.

Effects of Airborne Noise

The sound pressure level is one of the main acoustical factors that affect comfort. Maximum sound pressure level (Lmax) is typically used when predicting comfort with impact noise, whereas equivalent sound pressure level over a given period of time (Leq) is used for airborne noise. Other acoustical factors that impact acoustic comfort are:

Acoustic comfort is, however, highly subjective, and noise sources with the same physical characteristics can be perceived differently by different people. Personal and societal characteristics, such as sensitivity to noise and attitude towards a noise source, are essential when quantifying acoustic comfort.

Due to the physical and psychological effects associated with acoustic discomfort, some regional and international standards provide guidelines on noise level limits and other acoustic performance evaluation metrics. These metrics vary based on the purpose of the space and the type of effect noise will have on occupants. For instance, in residences, the main effects of noise exposure are annoyance, activity interference, and sleep disturbance, while in offices, effects on communication, work performance, and speech privacy are more important.

Standards and Guidelines

Standards and guidelines thus provide different background noise level limits for different spaces to ensure minimum interference with the activities performed in the spaces.

The World Health Organization (WHO) for instance, identifies different noise level limits for several indoor spaces including residences, hospitals and schools. In open-plan offices, additional metrics, such as the speech transmission index, distraction distance, and privacy distance are typically used to quantify the performance of an office with respect to speech privacy as well as effects of speech on occupants’ work performance. The structure borne vibration limits are laid out by ISO 10816 & ISO 11204:2010 so that ABN & SBN are well addressed.

Drawbacks

Despite the available standards and guidelines, acoustic discomfort remains one of the most important comfort issues even in spaces that meet requirements set by standards. One reason for this is the lack of consideration of individual differences, such as noise sensitivity.

In addition, many guidelines fail to consider the effects of variable noise levels over time as well as variable noise sources.

For example, the focus of most guidelines for residential spaces is outdoor noise sources such as traffic noise, and outdoor community noise, but do not include indoor sources.

Machinery sound measurement

Measurements from machinery which constitutes a sound source should be taken at 1 m from the machinery.

Commander Srikanth (Retired) has 44

Commander Srikanth (Retired) has 44