Image Source: GearHeads/CC BY-SA 3.0/Wikimedia Commons

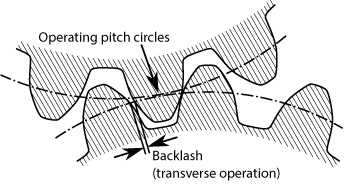

Backlash refers to the clearance or play between the mating teeth of bevel gears. This phenomenon is inherent to gear systems including bevel gears. Backlash in bevel gears differs from other types of gear clearances such as tip and root clearance, as it specifically refers to the axial movement or play between the gear teeth. Excessive backlash can lead to several issues that affect the overall performance and longevity of the gear system.

Cause of Backlash

Backlash in bevel gears can arise due to several factors; each of which contributes to the axial movement or play between the mating teeth. One primary cause is the inherent manufacturing tolerances and variations that are difficult to eliminate completely. Despite advanced manufacturing processes, achieving absolute perfection in gear tooth geometry is challenging. Variations in tooth thickness, profile deviations, and pitch errors can all contribute to increased backlash.

Another significant factor leading to backlash is misalignment during gear assembly or improper installation. Bevel gears require precise alignment to ensure proper meshing of teeth. Any misalignment in terms of parallelism, angular position, or center distance can result in an uneven distribution of load and lead to increased backlash. Similarly, inadequate mounting fixtures or incorrect positioning of the gears can introduce additional clearance between the teeth, exacerbating the backlash issue.

Furthermore, wear and tear over time can also contribute to increased backlash in bevel gears. Continuous usage and the effects of dynamic loads can cause the gear teeth to experience wear, resulting in changes in tooth geometry. As the gears wear, the original tooth contact patterns may shift, leading to increased clearance between the teeth and ultimately amplifying the backlash.

It is important to note that the specific causes and extent of backlash can vary depending on the manufacturing quality, installation precision, and operational conditions. Nevertheless, understanding these underlying causes of backlash is crucial for implementing appropriate measures to minimize its impact on gear performance. By addressing these causes through improved manufacturing processes, proper gear alignment and installation techniques, and regular maintenance, engineers can mitigate backlash and ensure the efficient and reliable operation of bevel gear systems.

Effect in Gear Performance

Excessive backlash in bevel gears can have significant effects on gear performance impacting various aspects of the gear system’s operation. Understanding these effects is crucial for assessing the overall efficiency and reliability of the system.

One primary effect of excessive backlash is a decrease in the gear system’s efficiency and power transmission capabilities. The presence of clearance between the gear teeth results in energy loss due to the axial movement during gear engagement. This energy loss translates into reduced power transfer efficiency, which can be particularly detrimental in applications where high efficiency is crucial.

Increased noise and vibration are common consequences of excessive backlash. As the gear teeth experience axial movement and impact during operation, it generates vibrations that propagate throughout the system. These vibrations result in increased noise levels, which can be undesirable in applications that require quiet operation. Additionally, the presence of excessive backlash amplifies the impact forces between the teeth, leading to heightened vibration levels that can compromise the smooth operation and longevity of the gear system.

Premature wear and potential damage to the gear system are additional effects of excessive backlash. The repeated impacts and sliding motion between the teeth can cause accelerated wear on the gear surfaces. Over time, this wear can lead to pitting, scoring, and even tooth breakage, compromising the overall integrity and lifespan of the gear system. In critical applications, such as aerospace or automotive transmissions, this can have severe consequences, including unexpected failures and costly downtime.

Another significant effect of excessive backlash is the reduction in accuracy and repeatability, especially in applications requiring high precision. Backlash introduces positional errors and hysteresis, making it challenging to achieve precise positioning and motion control. This can be problematic in robotics, CNC machines, or other precision equipment, where tight tolerances and reliable positioning are essential.

It is understood that excessive backlash in bevel gears can have detrimental effects on gear performance. It leads to decreased efficiency, increased noise and vibration levels, accelerated wear and potential damage, as well as compromised accuracy and repeatability. By minimizing backlash through proper gear design, precise alignment and installation, and regular maintenance, engineers can ensure the optimal performance, longevity, and reliability of bevel gear systems in various applications.

Ways to Reduce Backlash in Bevel Gears

Reducing backlash in bevel gears requires careful consideration and implementation of various strategies. By addressing the underlying causes and employing specific techniques, engineers can effectively minimize backlash and improve gear performance. Here are some key approaches to reducing backlash:

It is important to note that the specific approach to reducing backlash may vary depending on the application requirements and gear system design. Tailoring the implementation of these strategies to the specific gear system and considering factors such as load, operating conditions, and accuracy requirements is essential.

By adopting these measures and combining them appropriately, engineers can significantly reduce backlash in bevel gears, leading to improved gear performance, enhanced efficiency, reduced noise and vibration, and extended gear system lifespan.

Conclusion

Backlash in bevel gears is a critical consideration for ensuring optimal gear performance. By understanding the causes, effects, and available solutions to mitigate backlash, engineers and designers can make informed decisions when designing and implementing gear systems. Minimizing backlash through improved manufacturing processes, proper alignment, preload mechanisms, and anti-backlash devices helps enhance the efficiency, accuracy, and durability of bevel gear systems in a wide range of applications.