AGMA is pleased to announce the publication of two new revisions: ANSI/AGMA 2116-B24, Evaluation of Double Flank Testers for Radial Composite Measurement of Gears, written by the AGMA Gear Accuracy Committee, and ANSI/AGMA 6008-B24, Specifications for Powder Metallurgy Gears written by the AGMA Powder Metallurgy Committee.

ANSI/AGMA 2116-B24

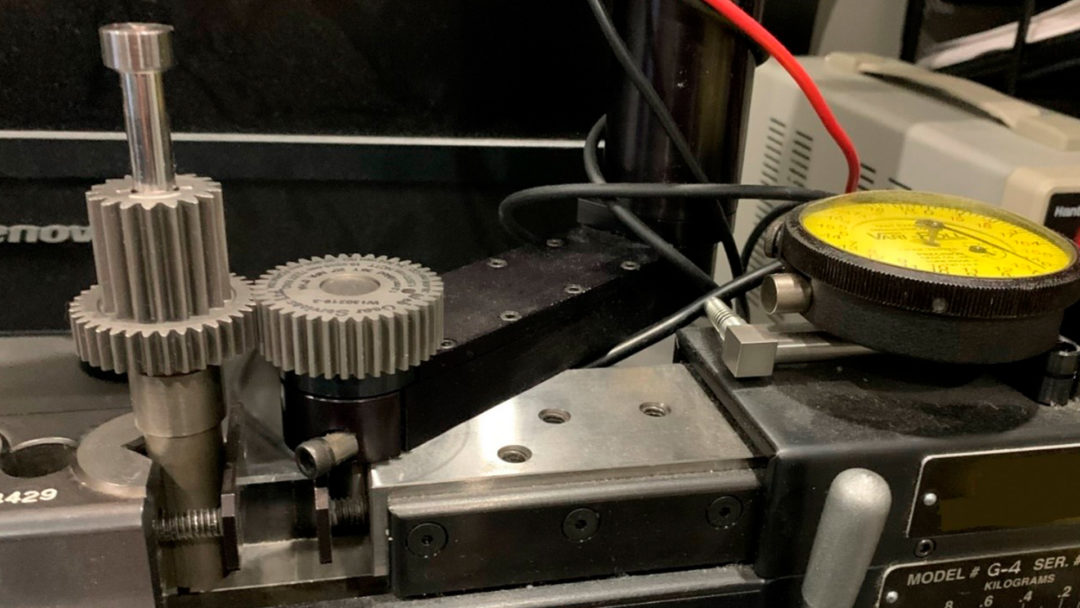

ANSI/AGMA 2116-B24 provides the evaluation criteria for double flank testers. It also recommends artifact sizes and geometry along with measurement system conditions. In Annex A of the standard a method for estimating calibration uncertainty is provided.

Between 1994 and 1998 the AGMA Calibration Committee published three standards on calibration of gear measuring instruments. The AGMA documents were used as the basis to create ISO 18653:2003 Gears – Evaluation of instruments for measurement of gears, and ISO/TR 10064-5:2005, Cylindrical gears – Code of inspection practice – Part 5: Recommendations relative to evaluation of gear measuring instruments. AGMA adopted the ISO standards, however the ISO standards did not cover evaluation methods of double flank testers. So the first edition of ANSI/AGMA 2116 was created in 2005 to fill in that gap.

This 2024 edition of ANSI/AGMA 2116 has incorporated information from an AGMA information sheet (AGMA 935-A05) into a new Annex A, titled Recommendations relative to the evaluation of radial composite gear double flank testers. Information from the former Annex B, Calibration certificate requirements, has been moved into the body of the document. Other changes are general updates to the latest practices.

ANSI/AGMA 6008-B24

ANSI/AGMA 6008-B24 provides comprehensive details for the design, processing, and specifications of powder metallurgy, PM, steel gears that need to be agreed upon between the PM gear supplier and the purchaser. These include: definition of terms, gear tooth geometry considerations, inspection, PM gear materials, drawing specifications, heat treatment, and mechanical testing.

The AGMA Powder Metallurgy Gear Committee was organized in 1993 to work on this specification standard. The first edition of ANSI/AGMA 6008 was published in 1998. This 2024 edition is a major update from the 1998 edition. There are 70 pages in the new edition compared to 17 pages in the old edition, 29 Figures compared to 8 figures, and 7 tables compared to 5 tables. A new Annex with guidelines for specifying a PM gear has been added. All sections from the 1998 edition have been greatly expanded including more details on how to specify, inspect, certify, and test PM steel gears and an extensive definitions section from ASTM B243-19 has been added.

On behalf of the gearing industry, AGMA would like to extend a sincere appreciation for the participation and the valuable contributions of the following experts. In addition, AGMA would like to especially thank the companies of these experts whose foresight and generosity made their participation possible.

ANSI/AGMA 2116-B24—AGMA Gear Accuracy Committee

Stevn Lindley of Regal Rexnord Corporation, Committee Chairperson

John Rinaldo of Atlas Copco Comptec (Retired), Committee Vice Chairperson

Mark Cowan of Gleason Metrology Systems Corporation

Roger Layland of Precision Gage Company

Ernie Reiter of Web Gear Services Ltd.

Brandon Terry of Triumph Gear Systems

Kris Terry of Triumph Gear Systems

Frank Uherek of Regal Rexnord Corporation

Christopher Wanasek of Caterpillar Global Mining LLC

Timothy Woodruff of Jet Avion Corporation

ANSI/AGMA 6008-B24—AGMA Powder Metallurgy Gearing Committee

Paul Crawford of PT Tech, LLC, Committee Chairperson

Ernie Reiter of Web Gear Services Ltd., Committee Vice Chairperson

Ian Donaldson of GKN Sinter Metals

Fred Eberle of Strattec Power Access

Robert Errichello of Geartech

Anders Flodin of Höganäs AB

Jacob Fritschle of Strattec Power Access

Jose Martinez Escanaverino of Atlantic Bearing Services

Ray Rupprecht of Metco Industries