Introduction:

One of the key aspects of the gear-grinding process is to focus on how best the stock allowance is removed.

This is important for controlling the grinding process time management, proportionate stock removal roughing and finish cuts to target towards the quality in grinding and most relevantly in the grinding process heat transfer into the cooling medium and managing the thermal stock in the tooth flank as the latter can cause grinding burn on the surface.

The excess heat on account of the chosen grinding parameters can penetrate into the flank surface to a shallow depth to induce unfavourable stress impact while the gear is in service.

The distortion of the flank besides radial but axial run-outs too in heat treatment renders its tooth flank topography non-uniform on the stock distribution.

The better stock is laid over the flank across the contact line evenly as well as balanced between the left and the right flanks of the tooth, the better the grinding forces on the tooth surfaces. This provides a uniform grinding structure below the surface and a burn-free flank.

With the above provisions targets towards precise quality of ground surfaces suitable for applications in the energy, aerospace, turbine class and speed- reduction Including marine gearings is possible.

Such requirements on tooth quality in grinding attempts towards productivity by new practical concepts using power dressing, variants in grinding strategy adaptation of new cooler grinding wheels, quick stock divisions of hardened tooth flanks for wheel entry and so on have been implemented,

We have also seen in practice for quality orientation -twist-free grinding in two flank grinding method

with multiple axes control, roughing and finishing with grinding wheels of choice, the least unbalanced management and surface finish oriented dressing have become useful and applied methods.

Tooth Frank heating and parameters:

While exercising roughing and pre-finish grinding with relevant specific material removal rate- Qw’ in mm3l mm/second, the selection of appropriate.

1. Depth of radial or infeed cut in the desired form of flank directional quantity.

2. Axial grinding feed rate to get the required Qw’ is important.

While rough grind phases are dependent on the material removal rate and in accordance with the selected volume removal parameters such as tv and Vf (infeed based on stock allowance uniform removal rate and axial feed rate) the quality of gear before finishing cut is important to where it has brought the work gear.

So the finish cycle is properly managed to balance the effect of previous cuts by the parameters.

This alone gets the finish stage gear for its dressing frequency of dressing to connect the surface grinding finish.

Therefore, measurement or interpretation of the surface temperature of finished ground gear is important.

Thermal characteristics:

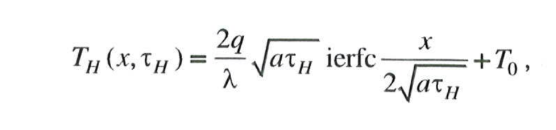

With the evaluation of heat flux, depth of cut, feed value used applying the Carslaw-Jaeger model with heat conductivity of gear material, and temperature conductivity of medium, one can estimate:

1. the temperature of the heating in the grinding

2. heating time

3. cooled Surface temperature

4. cooling time

to figure out the relationship between evaluated parameters on the grinding process parameters, equation (1) for the TH and Tc is shown, which is self- explanatory:

Where

TH the heating temperature

q is the rate of heat flux

λ is the heat conductivity

α Is the temperature conductivity X is the radial depth increment

tH is the Heat energy

T0 is the ambient temperature.

Out of the total generated heat, much goes into the cooling oil / grinding oil / its volume, flow rate through convection rate and conductivity. A portion of heat flux gets into the material.

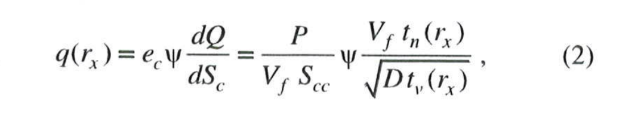

The relationship is:

Where

q(r) is the rate of heat flux penetrating at radius rx with reference to the gear axis

Q is the total energy

Ψ is the portion of heat energy penetration into the gear tooth

D is the grinding wheel instantaneous diameter

tn, tv, are the depth cut value of the material relative to the normal direction of the tooth and across the grinding allowance direction respectively.

Therefore, with a known type and method of applying coolant to control the temperature at the cooling time interval, it is possible to control the convection

coefficient, magnitude of the outlet oil temperature, grinding method, regulating its depth tv and feed Vf.

1. The value of the tv affects the maximum heating temperature.

2. The value of vf determines the time for heating and cooling.

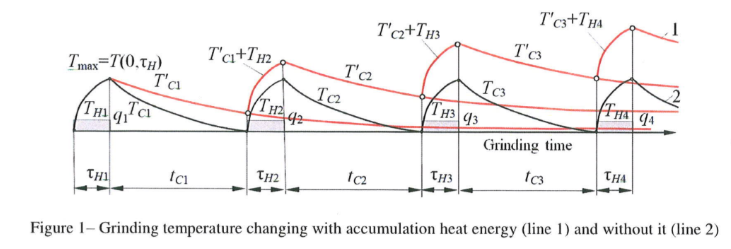

The grinding temperature growth can be seen in the following Figure 1

The behaviour of the rate of heating, attained temperature, rate of cooling and attained cooling temperature have been connected in relation to the feed by choosing the parameters such as depth of cut, dressing and climb or convectional mode of grinding and monitoring the coolant regulation.

Grinding and Barkhausen Test:

The fact that the heat content is absorbed into the flanks and allowed to accumulate can result in:

1. Tensile stress at the surface and to a small shallow depth in the substrate, other than compressive stresses of the residual stress content.

2. A change in hardness.

3. A possible structural change depending on the extent of exposure to thermal gain.

The surface integrity in essence can alter at different depths and manifest in the form of tensile residual stresses as a result of grinding burn.

The change in structure is usually tested by Nital Etching. This method uses the effect of component material vulnerability to acids. As the green effect is taking an important stage in production this method is facing limited use, another fact is that Nital Etch testing is applicable to surface and below-surface structures are not fully/efficiently handled.

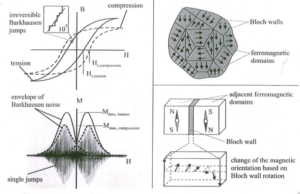

The alternative method is the Barkhausen Noise method. The basic features are:

● The material’s microstructure alters the Barkhausen Noise.

● The inclusions in the material, vacancies created by the departure of non-metallic inclusions, impurity atoms and mechanical stress state all affect the magnetisation process.

● The ferromagnetic properties include mainly two, among others. These are domains without external Zmagnetic field influence, These are Weiss Domains which carry a number of other domains as well which are separated by block walls allowing magnetic vectors. These vectors under the effect of external magnetic fields change the movement/ rotation of these vectors that are orthogonal to block walls.

● The other property of the ferromagnetic field/ domain is the Hysteresis loop.

The Principle

Figure 2 Characteristics of Ferromagnetic materials

● An external magnetic field initiates alternation

of Weiss domain orientation along the line of least resistance when unfavourable magnetic orientation increases.

● The block wall movement increase takes place and the stepwise increase is discontinuous. The irregular changes of magnetisation are the reason for this stepwise behaviour. These discontinuous jumps are audible and can be made audible.

● The change in magnetic structure by the wall movement is due to basic mechanical stresses in the substrate. The resistance to the mobility of the wall decreases with the increase in tensile residual stresses. This causes the Barkhausen signal amplitude Mtensile to grow.

● Electromagnetic fields influence the Barkhausen signal as well, which gives rise to the need for signal calibration.

● The application was first introduced in the 1980s and increasingly used since then.

● It is possible nowadays to adopt solutions to gear surface measurements for gear inspection.

● A proper handling procedure for a proper calibration is required, lest the result can contain errors.

Conclusion:

1. In order to attain signal up to thermal damage, the material removal rate proportionately increases. After grinding, the gears were tested with Nital Etching.

2. The test using BNA (Barkhausen Noise Analysis) shows: that some of the gears checked with Nital Etch for grinding burn required further testing.

This was due to the fact thermal damage could have occurred in rough grinding and finish grinding could have induced fresh compressive stresses in

its external zone. This can be due to the sub-surface grinding burn.

3. In some gears, the residual stresses suddenly change to tensile residual stresses under the surface of its tooth flank. The thermally affected parts that tempered zone evolve deeper, at times 250 to 300 microns from the surface. Unlike Nital etching, the Barkhausen signal increases at changing residual stresses. This can allow the process to be used for controlling the grinding operation by interrupting and taking corrective action to avoid errors.

The references to the article are:-

1) B Karpuschewski, O. Bleicher, M. Beutner / CIRP Conference on Surface Integrity – Surface integrity inspection on gears using Barkhausen noise analysis – 2011.

2) Lishchenko NV, Larshin VP – Profile Gear Grinding temperature reduction and equalization / Journal of Engineering Sciences Volume 5 issue 1 / 2018.

The author is former Director and General Manager of Gleason Works India. He has four decades of experience in the gear industry, with special reference to machine tools and gear processes. He is also a Fellow of the Institution of Mechanical Engineers, UK, and a registered chartered engineer.