The manufacturing world constantly evolves with engineers and researchers pushing the boundaries of what’s possible. In an era of precision engineering, the manufacturing of spiral bevel gears is crucial, particularly in applications like automotive, aerospace, and industrial machinery. To enhance the efficiency and accuracy of this intricate process, a novel CAD-based simulation model for manufacturing spiral bevel gears through face milling has emerged, promising a paradigm shift in gear production.

Understanding Spiral Bevel Gears:

Spiral bevel gears are essential components in many mechanical systems, providing torque transmission between intersecting shafts. The complex geometry of these gears demands precision manufacturing techniques to ensure optimal performance and longevity.

Challenges in Traditional Manufacturing:

Traditional manufacturing methods for spiral bevel gears often face challenges in achieving the desired accuracy and efficiency. The intricate nature of these gears with curved and angled teeth requires innovative approaches to overcome machining difficulties and enhance the overall manufacturing process.

Enter CAD-Based Simulation:

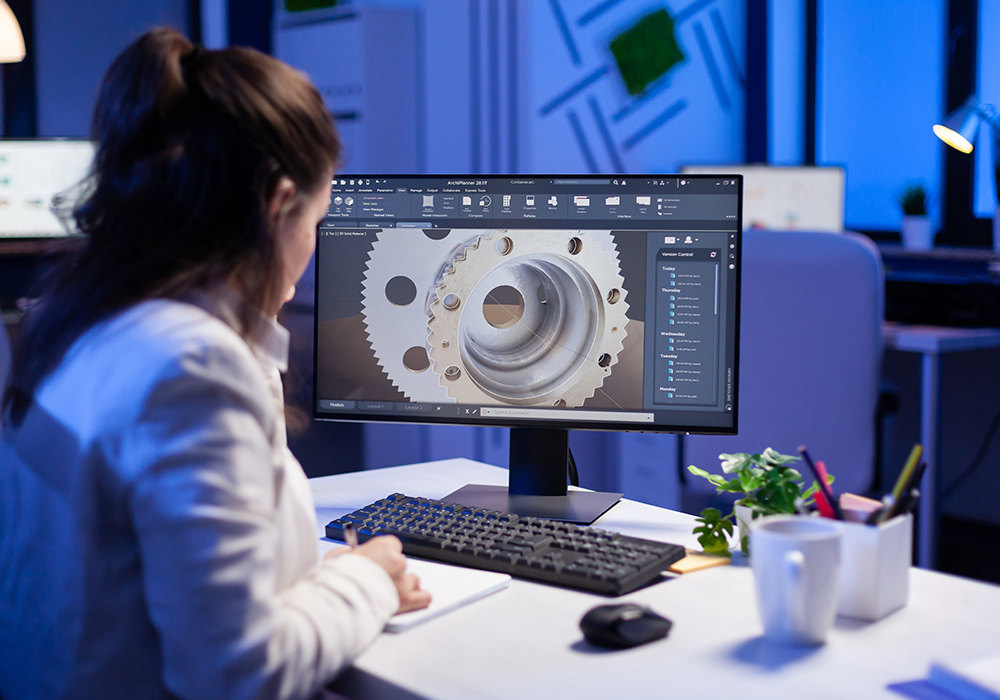

The integration of Computer-Aided Design (CAD) technology has been a game-changer in various industries, and the manufacturing of spiral bevel gears is no exception. The novel CAD-based simulation model takes the precision of gear manufacturing to new heights, offering a virtual environment to simulate the face milling process with unparalleled accuracy.

Key Features of the CAD-Based Simulation Model:

Virtual Prototyping:

The CAD-based simulation model allows engineers to create a virtual prototype of the spiral bevel gear, enabling a comprehensive analysis of its geometry and structure before the actual manufacturing process begins.

Optimized Toolpath Planning:

The model facilitates the planning of the toolpath for face milling, considering the specific geometry of the gear. This optimization ensures efficient material removal and reduces the likelihood of errors during the actual machining.

Realistic Material Removal Simulation:

Through the simulation, engineers can visualize and analyse the material removal process in real time. This aids in identifying potential issues, optimizing cutting parameters, and refining the overall manufacturing strategy.

Performance Analysis:

The CAD-based simulation model allows for a detailed analysis of the gear’s performance under different operating conditions. Engineers can assess factors such as stress distribution, load-bearing capacity, and efficiency, contributing to the development of gears with enhanced functionality.

Benefits of CAD-Based Simulation in Face Milling:

Reduced Prototyping Costs:

Virtual prototyping significantly reduces the need for physical prototypes, saving both time and resources. Engineers can iterate and refine designs in the virtual environment before moving to the actual manufacturing stage.

Enhanced Precision:

The precision offered by CAD-based simulations ensures that the face milling process is executed with a high degree of accuracy, resulting in gears with tight tolerances and optimal performance.

Faster Time-to-Market:

By streamlining the design and manufacturing process, the CAD-based simulation model accelerates the time-to-market for spiral bevel gears. This is particularly valuable in industries where rapid innovation and product development are essential.

Customization and Flexibility:

The virtual environment allows for easy customization of gear designs and facilitates quick adjustments to meet specific requirements. This flexibility is crucial in addressing the diverse needs of different applications.

Conclusion:

The introduction of a novel CAD-based simulation model for manufacturing spiral bevel gears through face milling marks a significant leap forward in precision engineering. By leveraging the power of virtual prototyping, optimized toolpath planning, and realistic material removal simulations, engineers can achieve a level of accuracy and efficiency that was once challenging with traditional methods.

As industries continue to demand higher performance and reliability from mechanical components, the integration of innovative technologies like CAD-based simulations in gear manufacturing becomes not just a choice but a necessity. This approach not only enhances the quality of spiral bevel gears but also sets the stage for future advancements in the ever-evolving landscape of manufacturing.