In recent years, achieving high gear accuracy has become a paramount priority in ensuring optimal performance across various applications. For instance, the automotive industry is undergoing a significant transformation with the rapid adoption of electric vehicles (EVs). Projections indicate that EVs could account for approximately 42% to 58% of global car sales by 2030.

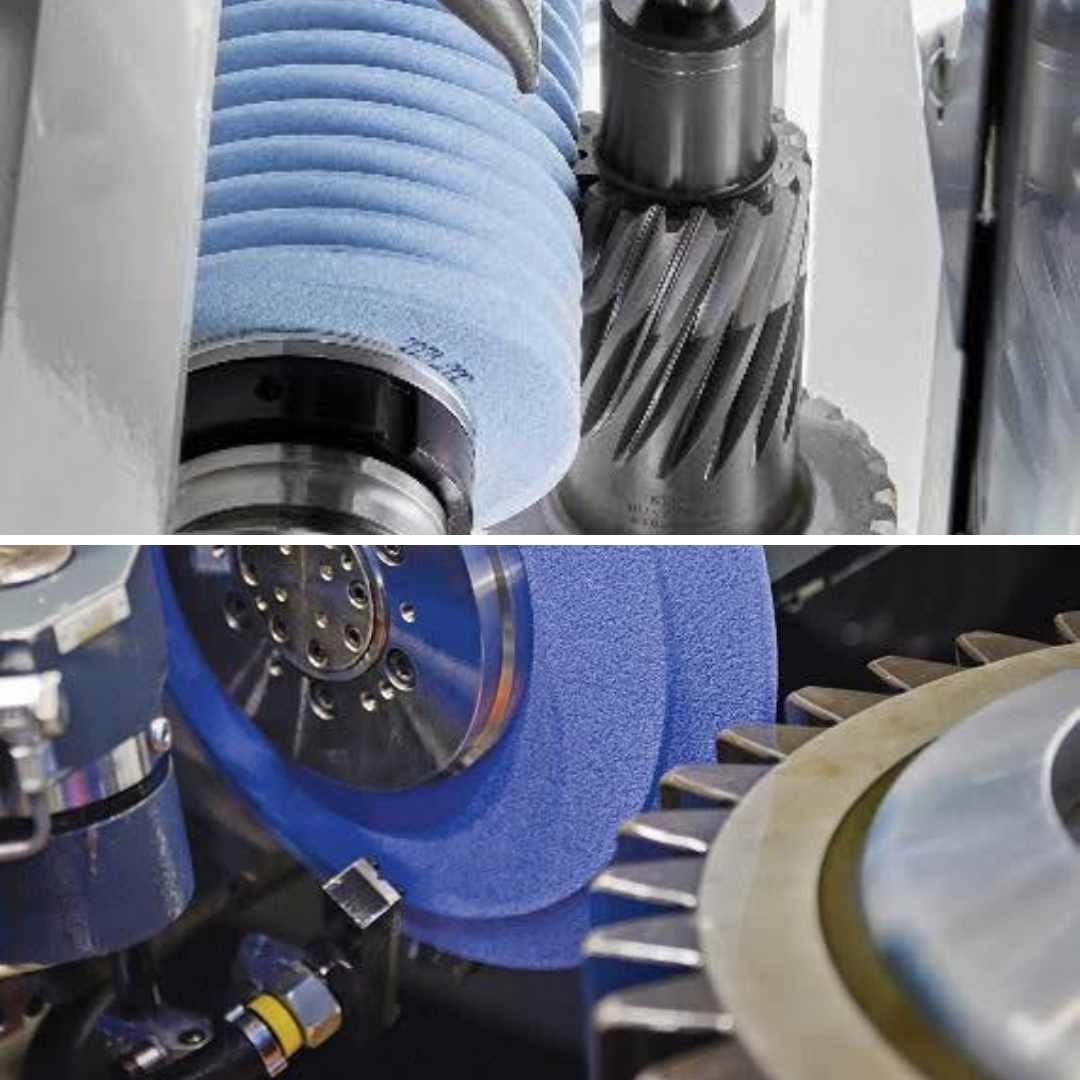

In EVs, noise reduction is a significant concern. The absence of an internal combustion engine makes other noises, such as gear noise, more noticeable. The precision of gears is crucial in minimizing this noise, and grinding processes play a major role in achieving the necessary accuracy.This article explores two key grinding methods—Gear Generation Teeth Grinding and Profile Teeth Grinding delving into their principles, applications, and guidance on selecting the appropriate method for specific scenarios.

| SLN | Factor | Generation Gear Grinding | Profile Teeth Grinding | ||

| 1 | Workpiece Size | Ø10 to Ø 500 mmModule 0.5 to 8 | Ø150 to Ø 5000 mmModule 0.5 to 50 | ||

| 2 | Grinding Wheel | Grinding worm | Single Rib profile wheel | ||

| Multistart (1 to 7 start) | Gap by Gap tooth Grinding | ||||

| 3 | Lead Crowing Achieve | 5–20 µm | 10–80 µm or more. | ||

| 4 | Root Grinding Capability | No, root grinding is not feasible | Yes, allows precise root modifications | ||

| 5 | Surface Finish Classification | DIN 5-7, AGMA 11-13 | DIN 4-6, AGMA 12-14 | ||

| 6 | Production Volumes | High Volume, Mass production | Low to Medium volumes, Specialized Gears | ||

| 7 | Precision | Good, but slightly less precise than profile grinding | High, suitable for high- accuracy gears | ||

| 8 | Cycle Time | Shorter, due to continuous rolling action | Longer, as it grinds individual teeth | ||

| 9 | Cost | Lower per unit for large production runs | Higher per unit due to slower process and precision | ||

| 10 | Application | Automotive, Industrial etc. | Wind Power, Ship Builder, Aerospace etc. | ||

Based on the comparison above, we can determine the most suitable grinding method for our part by considering factors such as production volume, gear design complexity, precision requirements, and cost efficiency.

Generation Gear Grinding

When designing and manufacturing gears with generation teeth grinding, key factors such as gear geometry, material selection, and critical decisions about machine choice, fixture design, and heat treatment methods are crucial to optimize the process for quality, performance, and cost-effectiveness.

Fixture directly impact on process parameters, so choose fixture according to volume.

The theoretical stock allowance per flank typically ranges from 0.10 mm to 0.50 mm. If heat treatment (HT) causes significant deformation, a deformation factor should be applied based on the extent and shape of the part. For example:

Adjust the deformation factor accordingly to ensure that an adequate stock allowance is maintained for grinding.

| Stock Allowance | 0.12 mm | 0.18 mm | 0.24 mm | 0.30 mm | 0.36 mm | 0.42 mm | 0.50 mm |

| No of Strokes | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

Typically, the last 1–2 passes are reserved for finish grinding, where a reduced feed rate is used. This approach ensures a finer surface finish and achieves the desired precision without excessive material removal.

Example- No of Teeths= 27, No of Start= 2 or 5

Double Radius Form Roll Single Taper Disc Double Taper Disc Composite Diamond Roll Profile Diamond Roll

The Double Taper Disc is widely used due to its high precision, longer life, and stability, making it ideal for consistent dressing and superior surface finishes. The dressing cycle and grinding wheel RPM should be selected based on the dresser type and desired part quality. Proper selection ensures optimal performance, tool longevity, and a high-quality finish.

Note: Ensure the use of appropriate process parameters to prevent common issues such as grinding burns and chatter marks on gear teeth.

Profile Gear Grinding

To produce parts using profile grinding, it’s essential to focus on factors such as the part type and its geometry. Based on these, select the appropriate machine and grinding wheel type. Next, consider parameters like stock allowance, grinding approach, specific material removal rate (Qw), axial feed, and chip volume (Vw) to determine the optimal dressing cycle.

We will explore what needs to be adapted at each stage of the part during profile grinding.

4. Material Removal Rate (Qw) – Depend on Module & Heat treatment method.

Module Consideration: The appropriate and adaptable Qw can be defined based on the module for efficient material removal.

5. Axial Feed- Based on factors like material type (softer materials allow higher feed), grinding wheel type (harder wheels need slower feeds), surface finish requirements (slower feed for finer finish), part geometry (complex shapes need slower feed), material removal rate (Qw), and machine stability. Balancing these factors ensures effective grinding while maintaining precision and part quality.

6. Chip Volume- For the roughing cycle, higher chip volume (Vw) is used, influenced by factors like larger module, heat treatment, diameter, and face width to remove more material quickly. In the finishing cycle, lower chip volume is preferred to achieve a smooth surface finish, with smaller chip volumes influenced by smaller module, heat treatment, diameter, and narrower face width. Roughing focuses on efficient material removal, while finishing prioritizes precision and surface quality.

So based on decided chip volume we can calculate after how many no of teeth we can dress the wheel in each cycle by using below formula-

Vw= Chip volume (mm3/mm)

ae= Total radial infeed (mm)

Z= Face width of gear (mm)

7. No of Passes- Generally we followed the profile grinding by 2 passes (Roughing & Finishing)

Roughing Pass- We need to define no of strokes based on Rouging stock (from total stock we need to keep 0.04 to 0.05 mm for finish) rest we need to remove in roughing cycle.

Example= Total stock allowance= 0.34 mm

Roughing Stock= 0.295 mm⭢ Calculate Infeed normal per flank for roughing⭢ Qw X SinPressure angelX60Axial Feed⭢ Total Stock/Infeed stock = No of strokes in roughing.

For Example, Qw= 6

Pressure Angle= 25° (Radian= 0.436)

Axial Feed= 4500

Infeed Normal per flank= 6 x 0.436 x 60/ 4500= 0.034 mm

Roughing Strokes= 0.295/0.034= 9 strokes

Finish Stock= 0.045 mm (here use 2 strokes max)

8. Grinding Approaches – We need to determine the appropriate grinding approach based on the desired final quality of the part.

| Grinding Approach | Machine with Twist Control | Lead Crowing Limit |

| Double Flank Completely | Yes | <0.035 |

| Double Flank Roughing+Single Flank Finishing | Yes | 0.035 to 0.055 |

| Single Flank Completely | Yes | 0.055 to 0.080 |

| Double Flank Roughing+Single Flank Roughing+Single Flank Finishing | Yes | >0.025 +Root Grinding |

| Double Flank Completely | No | <0.015 |

| Double Flank Roughing+Single Flank Finishing | No | 0.015 to 0.035 |

| Single Flank Completely | No | 0.035 to 0.060 |

Once all the process parameters and approaches are set, we are ready to begin profile grinding. Before starting, ensure proper stone positioning to achieve optimal grinding contact and accuracy. It’s also essential to closely monitor the process to avoid issues such as grinding burn, which can affect part quality. Keeping track of factors like grinding wheel sharpness, coolant flow, and feed rates throughout the process will help prevent overheating and maintain surface integrity. By following these precautions and maintaining close control over the grinding process, you can achieve the desired profile with high precision and minimal defects.