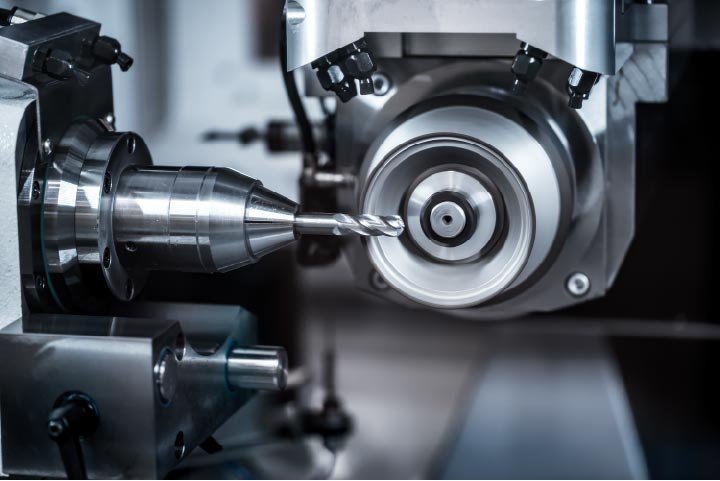

Machine tools form the foundation of gear manufacturing, playing a critical role in ensuring precision, efficiency, and reliability throughout the gear production process. Gears are integral to industries such as automotive, aerospace, railways, and industrial machinery, where accuracy and durability are non-negotiable. The evolution of machine tools has led to a paradigm shift in gear manufacturing, moving from traditional manual machining to CNC-driven, high-precision, and automated processes.

With the advent of multi-axis machining centers, gear manufacturers can now produce complex geometries with minimal material wastage. CNC hobbing, shaping, grinding, and power skiving have allowed for unprecedented levels of accuracy and efficiency. Additionally, automation in gear manufacturing, including robotic handling, predictive maintenance through IoT, and AI-powered quality control, has streamlined operations. These advancements have not only improved production speed but also ensured consistency, reduced human error, and enhanced overall cost-effectiveness.

As demand for high-precision gears rises globally, the role of machine tools in meeting these expectations becomes even more critical. With India aiming to be a manufacturing hub, its machine tool industry must continue evolving to meet domestic and international standards, pushing the boundaries of innovation in gear manufacturing.

India’s machine tool industry has witnessed significant growth, driven by factors such as rapid industrialization, increasing domestic demand, and government-led initiatives like the “Make in India” campaign. The sector has been strengthened by the push for self-reliance, reducing dependence on imported machine tools and developing indigenous capabilities. The machine tool market in India is expected to grow at a steady pace, with investments in automation, digitalization, and high-precision machining tools leading the way.

This growth has had a profound impact on the gear manufacturing industry. Indian gear manufacturers now have access to state-of-the-art machine tools that enable high-speed machining, improved surface finishing, and enhanced material efficiency. Companies are increasingly investing in CNC-based gear production technologies, reducing cycle times and increasing productivity. The automotive sector, a significant consumer of gears, has driven the need for advanced machining solutions capable of meeting stringent performance and durability requirements.

Additionally, the development of smart factories, where real-time data monitoring and predictive analytics optimize machining processes, has revolutionized gear production. The incorporation of Industry 4.0 principles is enhancing productivity, reducing waste, and ensuring quality control in gear manufacturing, making Indian firms more competitive in global markets.

India’s gear manufacturing industry is undergoing a transformation, with advanced machining technologies redefining production methodologies. Traditional gear manufacturing processes like hobbing and shaping are now being supplemented by modern techniques that enhance precision, efficiency, and sustainability.

Power Skiving has emerged as a game-changer in gear production, blending the advantages of shaping and hobbing. This method significantly reduces machining time, making it ideal for high-volume production. Power skiving also ensures better surface quality and dimensional accuracy, making it particularly useful for producing gears for electric vehicles (EVs) and aerospace applications.

Another notable innovation is dry hobbing, an eco-friendly alternative to conventional wet hobbing. By eliminating the need for cutting fluids, dry hobbing not only reduces environmental impact but also cuts operational costs. This method is gaining traction in industries seeking sustainable manufacturing solutions.

The introduction of hard finishing techniques, such as advanced grinding, honing, and skiving, has further refined gear manufacturing. These processes enhance gear surface quality, reduce noise levels, and extend gear lifespan, which is crucial for high-performance applications in the automotive and defense sectors.

Additive manufacturing (AM) is revolutionizing gear prototyping and production. With the ability to create complex geometries that were previously unachievable through traditional methods, 3D printing enables faster design iterations and reduces material waste. While still in the early stages for full-scale gear production, AM is becoming an essential tool for prototyping, repair, and small-batch manufacturing.

The integration of AI and machine learning in gear production is another breakthrough. AI-powered predictive maintenance minimizes machine downtime by identifying potential failures before they occur. Additionally, AI-driven tool path optimization enhances machining efficiency and extends tool life. Smart manufacturing powered by AI and IoT is helping Indian manufacturers reduce costs and improve consistency in gear production.

These advancements are positioning India as a leader in high-precision gear manufacturing. With increased R&D investment and the adoption of next-generation manufacturing processes, Indian companies are gaining global recognition for their ability to produce high-performance gears for critical applications.

The Indian government has introduced several initiatives and policies to promote the machine tool and gear manufacturing industries. Notable among them are:

These investments and policies are playing a crucial role in making India a competitive hub for high-precision manufacturing, attracting global players to set up production facilities in the country.

Despite its rapid growth, India’s gear manufacturing sector faces several challenges:

India’s gear manufacturing sector faces multiple hurdles that need urgent attention. The skill gap in advanced machining remains a persistent issue, as there is a lack of trained professionals capable of handling sophisticated CNC machines and interpreting complex gear production processes. Bridging this gap requires enhanced vocational training and stronger industry-academia partnerships.

Another major obstacle is infrastructure and supply chain inefficiencies. The inconsistent availability of high-quality raw materials, coupled with inadequate logistics networks, hampers smooth production workflows. These bottlenecks lead to increased lead times and higher manufacturing costs.

The slow adoption of Industry 4.0 technologies is another challenge, particularly among small and medium enterprises (SMEs). While large-scale manufacturers are embracing automation, digitalization, and AI-driven quality control, many SMEs struggle.

India’s gear manufacturing industry has immense potential for growth, with numerous opportunities emerging due to advancements in digital manufacturing, automation, and sustainability. The adoption of Industry 4.0 technologies, including smart factories, real-time monitoring, and AI-driven quality control, will be instrumental in driving efficiency and precision.

The rising demand for electric vehicles (EVs) is another key factor shaping the future of gear manufacturing. EVs require lightweight, high-efficiency gear solutions, presenting an opportunity for Indian manufacturers to develop innovative products. Additionally, the push for sustainability is encouraging the adoption of energy-efficient machining processes and recyclable materials, further aligning with global industry trends.

With strategic investments in automation, talent development, and R&D, India can establish itself as a leading hub for high-precision gear manufacturing. By embracing advanced machining technologies and sustainable practices, Indian manufacturers can compete with their global counterparts and expand their market reach.

To strengthen its position as a global leader in gear manufacturing, India must prioritize several key areas. First, bridging the skill gap is essential, which can be achieved through specialized training programs and stronger industry-academia collaborations. Equally important is the need to enhance infrastructure and build a resilient supply chain to ensure the consistent availability of high-quality raw materials and precision components. Accelerating the adoption of Industry 4.0 technologies—particularly among small and medium enterprises (SMEs)—will play a crucial role in boosting operational efficiency and global competitiveness. In addition, strengthening international collaborations will help facilitate technology transfer and elevate domestic manufacturing capabilities. Lastly, investing in sustainable manufacturing practices is vital not only to meet global environmental standards but also to reduce long-term operational costs and enhance industry resilience.