By: Chinnappan Selvaraj

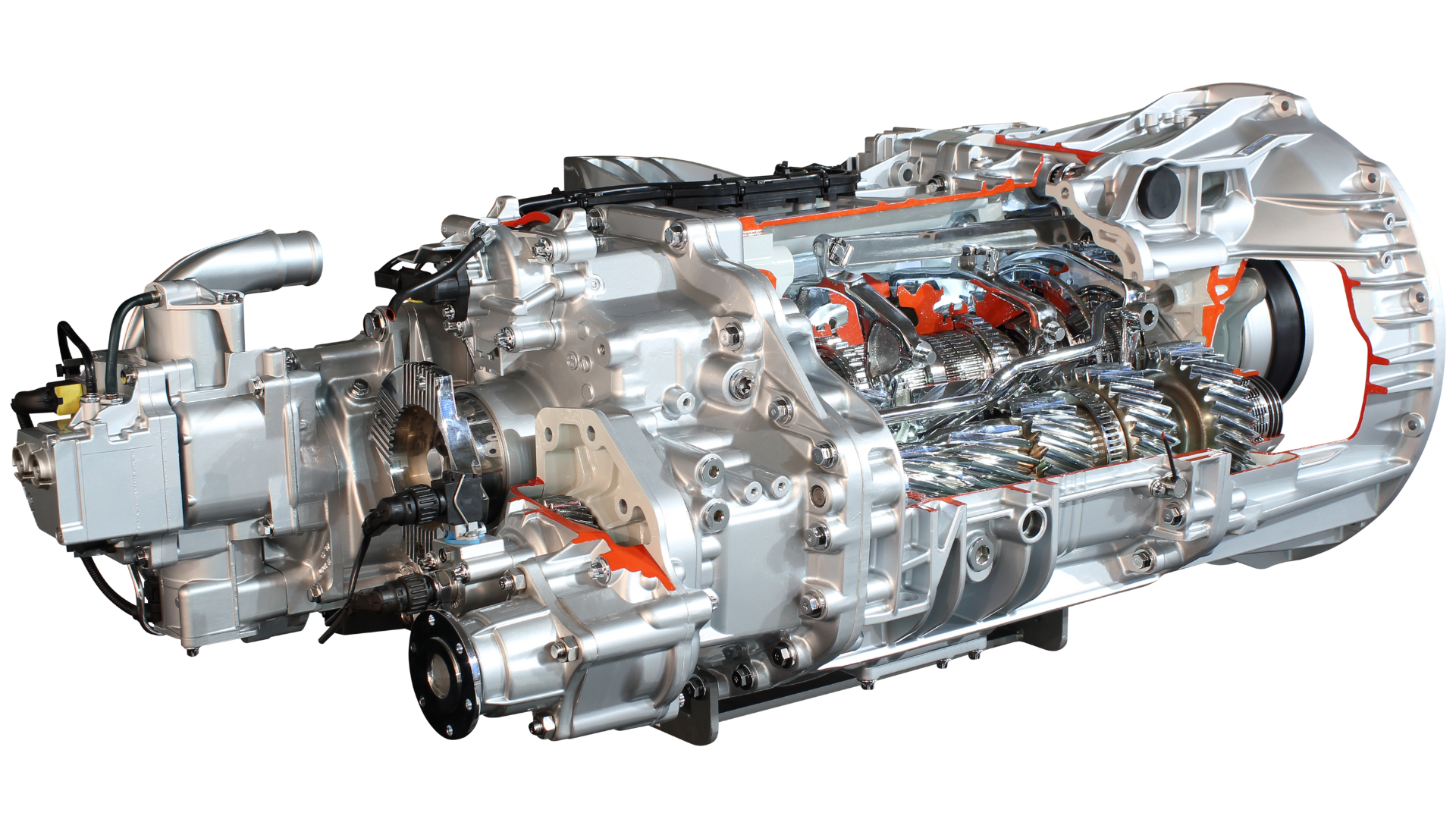

Machines over a period of time go through a lot of wear and tear. The gearbox is the heart and soul for any machine to keep running. To ensure its longevity, regular maintenance and servicing is a must.

Selection of raw materials/heat treatment/process

Forty years ago, gearbox manufacturers didn’t have many options before them. They would select raw materials based on what would be available at the time.

However, nowadays, while replacing a gear set during servicing, designers check the possibility of using the latest alloy steels to improve the rating of gearboxes.

In addition to this, they choose the gear tooth parameters to enhance the rating by selecting appropriate heat treatment processes such as carburising & case hardening, gas nitriding, induction hardening and profile grinding operation to name a few. Previously, a supplier may have used herringbone type gears without gear profile grinding, but to make the manufacturing easy now, designers may opt for double helical gear design with case hardened and profile ground designs. Therefore, in this manner, a good improvement on gearbox rating is attained.

Steps to be followed during repairing of gearbox housing

a) Housing bores to be enlarged. Top and bottom housing face to be machined

b) Housing to be dismantled as top and bottom housing

c) Depending on the bore worn out , housing bore to be welded with appropriate welding electrode in consultation with welding experts

d) Top and bottom housing to be rejoined

e) Re-boring of housing to be done using CNC Horizontal machining centre/CNC Horizontal boring machine

f) Bores to be inspected by CMM to ensure the correct center distance

Advantages of servicing gearboxes

The gearbox after servicing can run for an additional 5-10 years

The rating of the gearboxes can be improved by going in for service

They can incorporate the latest technology in old gearboxes also

Customers can avoid to going for capex for buying new gearboxes