TECHNOLOGY OUTLOOK

A “compact automation” denotes a mechatronic setup capable of independently executing a sequence of manufacturing steps. The term “compact” pertains to the diminutive size, typically in the millimeter and centimeter scales, of the items undergoing processing. STIWA, an Austrian machinery manufacturer, specializes in designing and building such systems, with its core focus being the development of the modular LTM-CI system tailored for small-part assembly. Integral to these systems are linear and rotating micromotors provided by Faulhaber, which handle crucial operations.

The valve, comprising only a handful of components and measuring a mere eight millimeters in length, serves as a component within the anti-lock braking system of a major automotive supplier. Demanded in quantities reaching the seven-digit mark annually, production necessitates a takt time of half a second to meet this volume. This production occurs entirely automatically and at a pace so rapid that discerning individual assembly steps with the naked eye becomes challenging.

In a narrow Alpine valley, tiny components undergo a meticulous process. Initially stored, they are then sifted and arranged on a conveyor belt for the first stage of manufacturing. At designated stations, precise grippers manipulate these components, either assembling them or subjecting them to further processing. The synchronized movements of the machine create a mesmerizing spectacle, blending the smooth flow of conveyor belts with the swift, controlled actions of the grippers, akin to an intricate dance.

This sophisticated operation is carried out by the LTM-CI series compact automation system from STIWA, designed for products measuring up to 30 mm in diagonal length. Roland Schiermayr, head of automation research and development, recounts how a client in western Austria required a more space-efficient production solution for dampers destined for a prominent furniture retailer. The existing 10-meter machine proved cumbersome for the valley site. Thus, STIWA embarked on maximizing miniaturization opportunities.

The outcome was a compact machine, spanning 3 to 4 meters depending on configuration, accommodating up to 22 function modules, each 90 millimeters wide. These modules encompass various tasks such as pick-and-place operations, laser welding, screw insertion, press-fitting, labeling, as well as testing and measurement processes.

The compact automation system has garnered praise from clients for its smooth, impact-free movements, likened to the precision of a sewing machine. With the LTM-CI, cycle times have been slashed to nearly half a second, resulting in a significant productivity boost.

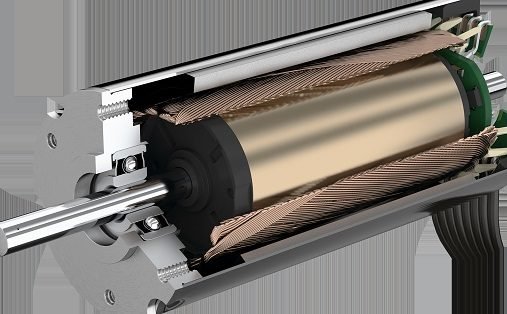

A key contributor to the system’s efficiency is the use of Faulhaber products, notably the LM 1247 linear motor, renowned for its speed and thrust capabilities. Additionally, the brushless motor of the BX4 2250 series drives swivel units critical for positioning tools and components accurately. Both motor types offer exceptional longevity and reliability, crucial for meeting STIWA’s commitment to delivering fault-free operation for at least 60 million cycles. Through rigorous endurance testing, Faulhaber motors have proven their ability to withstand extreme conditions, aligning with STIWA’s standards for peak performance in minimal space with minimal cycle times.