In today’s highly competitive and precision-driven manufacturing environment, quality and efficiency are more important than ever. This is particularly true in the world of gear manufacturing, where even minute errors in gear geometry can lead to excessive noise, vibration, wear, and eventual failure in automotive, aerospace, and industrial machinery applications. Traditionally, gear production has been a sequential process involving design, cutting, inspection, and manual correction. However, the concept of closed-loop manufacturing has introduced a transformative approach — one that feeds inspection results back into the machining process in real time or near real time.

Closed-loop gear manufacturing promises to compress development cycles, increase precision, reduce human error, and standardise quality. Yet the question remains: is it a mature, widespread reality — particularly in India — or is it still an elusive ideal?

Closed-loop manufacturing is a feedback-driven process where inspection results are automatically analysed and used to generate real-time adjustments to the machining operations. The goal is to create a self-correcting, intelligent manufacturing system capable of maintaining tight tolerances throughout production.

In gear manufacturing, a typical closed-loop system integrates three major components:

The result is a feedback loop that helps in iteratively refining gear geometries with reduced reliance on manual intervention or lengthy trial-and-error iterations.

The closed-loop process begins even before any metal is cut. Using sophisticated software like Gleason’s CAGE (Computer-Aided Gear Engineering), design engineers input key gear parameters—number of teeth, pressure angle, face width, etc.—and simulate contact patterns, motion smoothness, and load-bearing stresses. This helps in predicting gear behavior, enabling engineers to refine designs before proceeding to manufacturing.

In closed-loop environments, this design data is not siloed. It’s directly linked to CNC code generation and machine parameters, bridging the gap between digital modeling and real-world machining.

Machines such as Gleason’s Phoenix 250HC series are equipped with multi-axis CNC systems (often using controllers like Fanuc), capable of executing complex geometries for bevel, spiral, or hypoid gears. These machines feature:

Once the digital design is finalized, the software automatically generates machine settings and tool paths. These are transferred directly into the CNC gear cutter or grinder for trial part production.

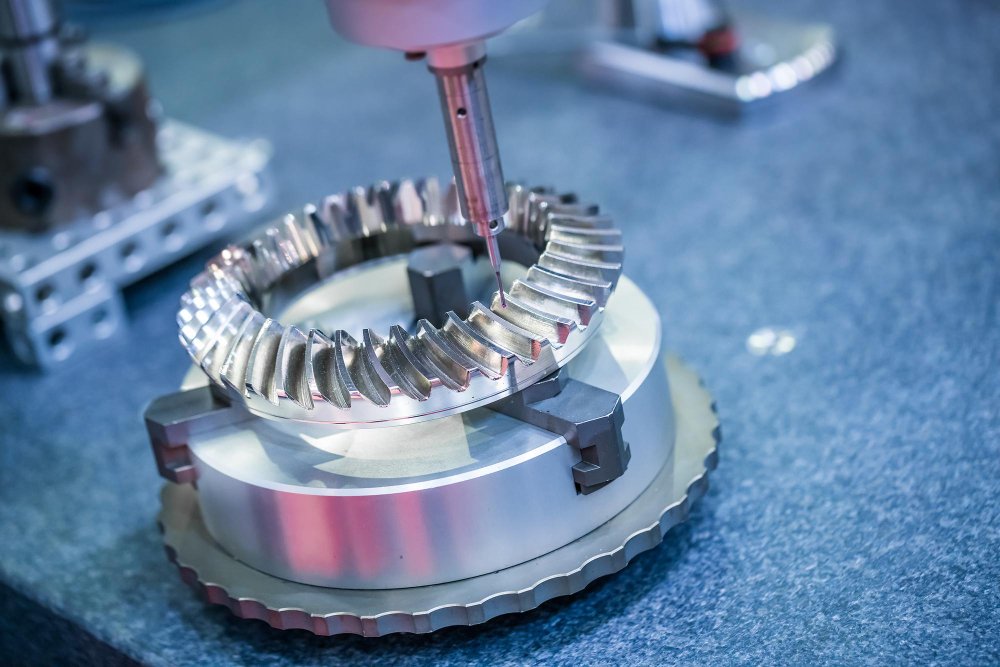

Inspection is carried out using high-resolution Coordinate Measuring Machines (CMMs) like Zeiss or Hofler gear testers. Using 3D probes and automated positioning systems, these machines can:

The inspection software (e.g., G-AGE by Gleason) compares the manufactured gear to the theoretical design, identifies deviations, and calculates corrective values.

The measured deviations are used to automatically generate corrections to the machine settings. These corrections are either:

Subsequent gears are cut or ground with the updated parameters. In most cases, only one additional trial is needed before achieving design-accurate gears.

Closed-loop gear manufacturing offers transformative benefits that directly address long-standing challenges in precision and productivity. One of the most significant advantages is the reduction in design-to-production cycles. Traditionally, a gear production trial-and-error loop could take 3–4 days, but with real-time feedback and automated corrections, this timeline can shrink to just a few hours. The system also delivers high first-time accuracy, producing gears with minimal deviations right from the initial run, reducing the need for costly rework.

Another compelling benefit is repeatability and consistency across production batches. By minimizing manual interventions and standardizing inspection and correction processes, closed-loop systems ensure uniform quality throughout. This leads to reduced human dependency, cutting down on the risk of operator-induced errors and minimizing the demand for highly specialized manual inspection.

Moreover, closed-loop systems are particularly adept at supporting complex gear geometries, such as spiral bevel, hypoid, and high-load gears, which require tight tolerances and intricate machining. A real-world example of this in action is Arrow Gear Company in Illinois, USA. By integrating Gleason’s closed-loop manufacturing system, the company was able to significantly cut down setup and iteration times while achieving improved consistency and precision in their spiral bevel gear production. This case underscores the real-world impact and scalability of closed-loop technology when effectively implemented.

One particularly innovative use of closed-loop systems is in reverse engineering legacy gear designs. For example, older gearmasters that were developed manually are now digitized using CMMs and analyzed with modern software. Their digital twins are then used to generate CNC machining instructions — enabling production of high-performance replicas using modern, efficient processes.

This is highly beneficial in automotive or aerospace sectors, where discontinued gear models still need servicing but cannot be sourced through conventional means.

India is home to a diverse spectrum of gear manufacturers — from world-class exporters to Tier 3 suppliers working with basic manual hobbing machines. While some top-tier Indian companies, especially those in automotive and aerospace sectors, have started integrating elements of closed-loop systems, widespread adoption remains limited.

Myths and Misconceptions

While the benefits are magnified in high-volume operations, even small batch manufacturers of precision gears (e.g., aerospace, robotics) can benefit immensely from closed-loop systems, especially in reducing iteration cycles.

On the contrary, it elevates their role. Operators become process engineers, data analysts, and digital system managers, enabling higher productivity and job satisfaction.

Modern software is increasingly modular, with user-friendly interfaces and standardised data formats. With proper planning and phased implementation, integration is achievable even in mixed-equipment environments.

To transition closed-loop gear manufacturing from a conceptual ideal to a widespread reality in India, several foundational pillars must be addressed. First and foremost is technology accessibility. SMEs, which form the backbone of India’s manufacturing sector, often struggle with high capital investments. Government-backed subsidies, leasing models, and financing schemes can make it easier for these companies to invest in critical technologies like precision inspection systems and adaptive manufacturing software.

Equally important is workforce training. The implementation of closed-loop systems demands a skilled workforce proficient in CNC programming, gear inspection techniques, and digital manufacturing tools. National initiatives like Skill India must evolve to include advanced modules on smart manufacturing to bridge this gap.

Next is the creation of robust vendor ecosystems. Collaboration between machine tool manufacturers, software developers, and inspection technology providers can drive the development of localized, cost-effective, and integrated solutions tailored to Indian manufacturing needs.

Further, the success of closed-loop systems depends heavily on data infrastructure. Real-time feedback and intelligent correction mechanisms require secure, high-speed factory networks, support for edge computing, and cloud-enabled platforms to allow seamless cross-machine data exchange.

Finally, pilot programs and demonstration cells are essential to inspire confidence and encourage adoption. Establishing these in technical institutions, industrial clusters, and MSME hubs can help manufacturers visualize ROI, test capabilities firsthand, and drive grassroots-level momentum toward smarter gear manufacturing practices.

Closed-loop gear manufacturing is no longer a futuristic vision — it’s a proven, scalable solution already delivering results across the globe. In India, while adoption is still in its early stages, the trajectory is promising. The convergence of digital design, automated inspection, and intelligent machining offers Indian gear makers a pathway to global quality standards, higher efficiency, and innovation readiness.

Whether you’re an OEM pushing for zero-defect gears or an SME looking to modernise your shop floor, closed-loop manufacturing isn’t a luxury — it’s a strategic necessity.

The myth has been debunked. What remains is a choice: to observe or to embrace the future of gear manufacturing.