Are you looking for mechanical components for converting rotary motion into linear motion with high efficiency without compromising precision? Then look no further than ball screws.

Large-scale industries such as automobile, aerospace, and medical make use of the ball screws as they play a crucial role in precision instruments and machinery tools.

The article focuses on varied aspects of ball screws such as the basic understanding, working principle and mechanism of the ball screws.

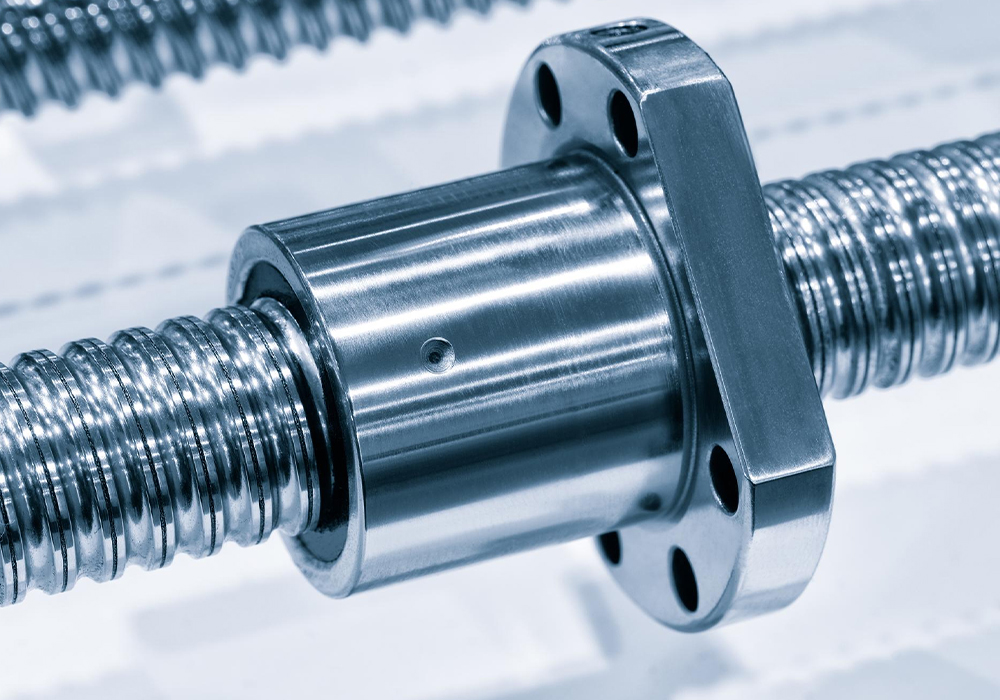

To understand the ball screw we need to first know the components of the ball screw which include screw, nut, steel balls, reverser, pre-compression piece and dustproof device.

The major function of the ball screw is to convert the rotatory motion to linear motion, which is done by transforming sliding motion to rolling motion.

In 1898, a groundbreaking idea emerged: it involved the use of steel balls positioned between the nut and screw to change the nature of contact from sliding to rolling. This transformation allowed for the rotational movement of the steel balls within the nut to be translated into linear motion. As a result, this innovation significantly enhanced torque conversion efficiency while minimizing positioning issues and damage compared to traditional screws.

The credit for inventing the ball screw goes to Rudolph G. Boehm from Texas, who obtained a US patent for this invention in 1929. In its active role, the nut is converted into linear motion in sync with the screw’s rotational angle, guided by precise specifications. The passive workpiece can be connected to the nut through a nut holder.

Are you into manufacturing ball screws for various industrial sectors? If yes then the upcoming IPTEX GRINDEX 2024 expo is the most apt place to showcase your unique product and connect with the industrial leaders.

Secure your slot at https://www.iptex-grindex.com/register.php

Don’t miss this golden opportunity for your product to reach the right industry.