Do you know that in the heart of every automobile, turbine, windmill, or heavy machine lies a component that never stops turning—gears? Yes, these mechanical marvels have been manufactured for centuries, but the methods for producing them are undergoing a radical transformation. As we are aware, gear hobbing, is one of the most critical and widespread gear cutting processes, is evolving in ways that were once the domain of science fiction.

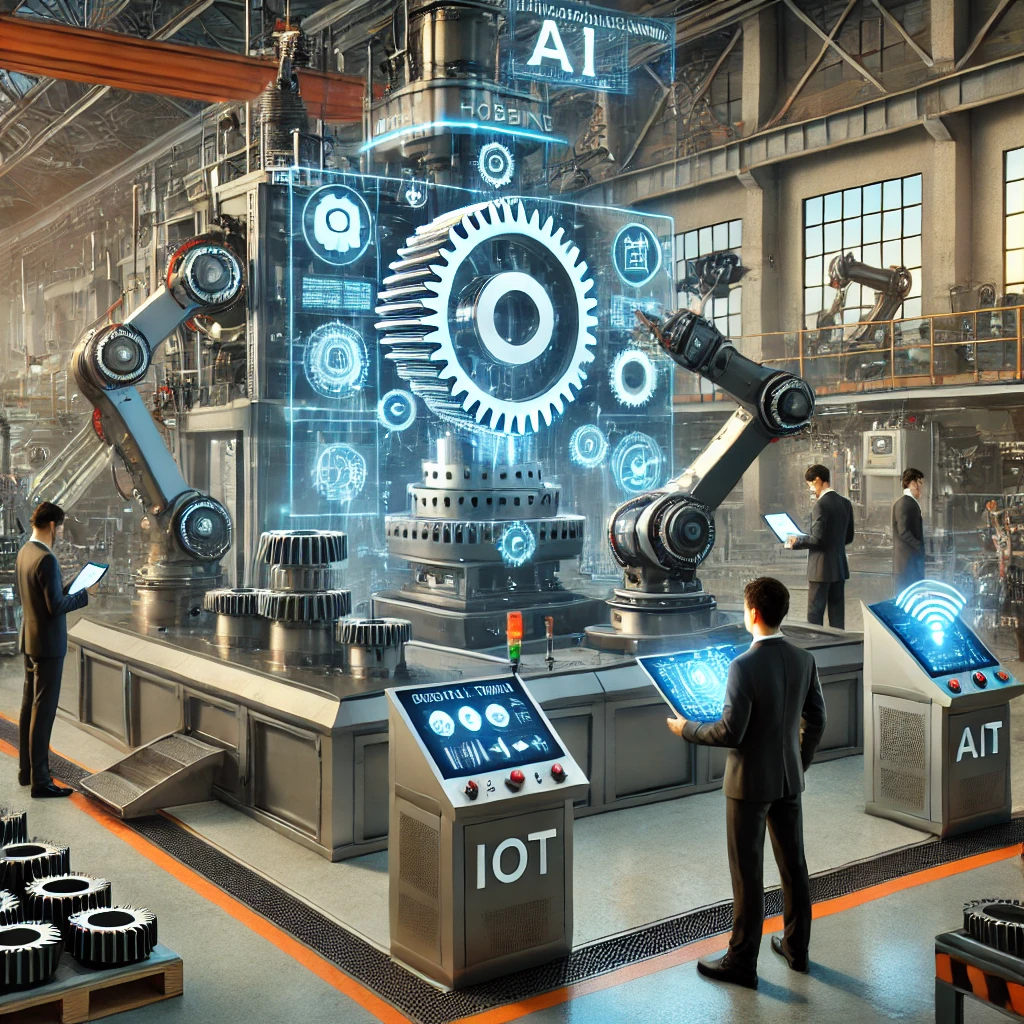

Artificial Intelligence (AI), machine learning, IoT, and cyber-physical systems are entering the gear shop floor, breathing new life into traditional hobbing machines. The new generation of smart hobbing systems combines the brute precision of traditional mechanics with the intelligence of digital technologies to unlock unprecedented levels of productivity, consistency, and agility.

India’s gear manufacturing sector—already an important global player—is witnessing this shift first-hand. In this article, we delve into how smart hobbing machines are reshaping manufacturing strategies, what technologies are leading the charge, and how Indian manufacturers are preparing for a future where AI meets steel.

Gear hobbing is a continuous cutting process where a hob (a cylindrical cutting tool) rotates in sync with the gear blank to generate gear teeth. Since the early 20th century, hobbing machines have evolved from manually operated gear-driven systems to CNC-controlled machines capable of high-speed, high-precision cutting.

But the fundamental principle remained unchanged—until now.

The introduction of advanced sensors, edge computing, cloud analytics, and AI algorithms has allowed manufacturers to not just control the hobbing process, but to optimize, predict, and autonomously correct it in real time.

We are witnessing a transformation from:

This is no incremental shift—it’s a technological leap.

Modern hobbing machines are now embedded with algorithms that monitor parameters such as spindle torque, vibration, temperature, and acoustic emissions. These systems “learn” from production runs and create digital fingerprints of optimal machining conditions. When something deviates—say, tool wear or material inconsistency—the AI flags it or autonomously adjusts parameters.

For example, a machine learning model can analyse historical data to determine the ideal feed rate for a specific gear size and material combination, improving both surface finish and tool life.

Smart hobbing machines are part of an interconnected ecosystem. Data from each machine can be streamed to a central control system, where managers can monitor production metrics, tool usage, and maintenance needs remotely. This creates a fully transparent and agile manufacturing environment.

By creating a real-time virtual model of the hobbing machine and the workpiece, manufacturers can simulate gear cutting processes before running them on the shop floor. Digital twins allow for error prediction, design validation, and process optimisation without wasting raw material.

Advanced hobbing machines now feature in-line measurement systems, such as laser scanning and probe touch sensors, that compare the actual tooth geometry against the design intent during the process. Deviations trigger automatic compensation without operator intervention.

India’s gear manufacturing industry—valued at over ₹10,000 crore—is gradually embracing smart hobbing. Automotive giants, Tier-1 suppliers, and precision gear manufacturers are investing in intelligent machines to meet the growing demand for quality, efficiency, and traceability.

Bharat Gears, one of India’s largest gear manufacturers, has recently piloted a smart hobbing cell that integrates sensor-based monitoring with AI-driven adaptive control. According to their plant engineering team, tool life has improved by 18%, and machine downtime has been reduced by over 20% due to predictive maintenance algorithms.

“Digital hobbing isn’t just about better gear quality. It’s about having a system that tells us when to intervene and why. That’s a game-changer for planning and quality assurance,” says a senior manufacturing engineer at Bharat Gears.

Even smaller job shops are exploring retrofitting older hobbing machines with smart add-ons. Companies like Aikon Technologies and Micromatic are offering modular IIoT kits that provide real-time insights without requiring a complete machine overhaul.

Traditional hobbing machines—while reliable—often depend heavily on the operator’s skill to maintain consistency in gear cutting. With AI-powered systems, this variability is drastically reduced. Smart hobbing machines use real-time data from torque sensors, spindle load, thermal variations, and vibration patterns to fine-tune the process on the fly.

This dynamic optimization enables tighter tolerance control, often within microns, which is especially critical in applications such as:

By reducing human-induced variation and enabling automatic in-process corrections, smart hobbing ensures every gear off the line is as precise as the first.

In conventional gear manufacturing setups, machine maintenance typically follows a reactive or calendar-based schedule. This approach either leads to unplanned downtime due to sudden failures or premature servicing that wastes resources.

Smart hobbing machines equipped with predictive maintenance algorithms change the game. By continuously monitoring machine health indicators—like spindle temperature, lubrication flow rate, gear backlash, and tool vibration—AI systems can detect early warning signs of wear or failure.

This allows for:

Especially in India, where supply chain disruptions and service delays are common, predictive maintenance adds a vital layer of resilience.

Although the capital cost of smart hobbing machines is higher, their operating efficiency leads to significant cost savings in the long run.

Here’s how:

In high-volume production environments—like automotive component manufacturing or industrial gearboxes—even a 1–2% reduction in scrap or tool consumption translates into lakhs of rupees saved annually.

As smart hobbing becomes more widespread, the role of the machine operator is shifting from manual intervention to strategic oversight. Instead of tweaking knobs and adjusting backlash manually, operators are now expected to:

This transition not only improves operational reliability but also opens doors for workforce development. In India, where the manufacturing labor force is extensive but unevenly skilled, this evolution represents a chance to bridge the gap between shopfloor work and smart manufacturing careers.

Vocational programs, government initiatives like Skill India, and OEM-led training centres can help accelerate this upskilling journey.

While the benefits are compelling, adopting smart hobbing technology is not without its roadblocks—especially for the small and medium manufacturers that form the backbone of India’s gear industry.

High Initial Investment

A smart hobbing machine—with integrated sensors, closed-loop control, and cloud connectivity—can cost 30–50% more than its conventional CNC counterpart. For large OEMs and Tier-1 suppliers, this cost may be manageable, especially when justified through long-term ROI.

However, for MSMEs, which dominate India’s gear manufacturing sector, such an investment poses a serious financial hurdle. While the payback in terms of productivity and quality is clear, it often takes 2–3 years to fully realize—an uncertain prospect for small businesses facing daily cash flow challenges.

Solution Paths:

The move to smart hobbing isn’t just about machines—it’s about people. Operating AI- and IIoT-enabled systems requires a blend of mechanical knowledge and digital literacy. Many current operators, especially those trained in traditional machining, find it difficult to adapt quickly.

Key skill gaps include:

Solution Paths:

Smart hobbing relies on a robust digital infrastructure—reliable high-speed internet, secure cloud platforms, and cyber-resilient factory networks. Unfortunately, many industrial areas in India suffer from:

Without this foundation, features like remote monitoring, cloud analytics, or firmware updates become infeasible.

Solution Paths:

Most Indian gear manufacturers still use older mechanical or semi-CNC hobbing machines, many of which are amortised but still functional. Replacing these machines entirely isn’t always viable.

While retrofitting solutions exist—such as bolt-on sensors, PLC upgrades, and IIoT gateways—they often have limited scope:

Solution Paths:

As smart hobbing technology matures, we are moving beyond isolated machine intelligence to a fully integrated digital ecosystem. The future of gear manufacturing will not only be smarter—it will be autonomous, connected, adaptive, and sustainable. Here’s a look at the key innovations on the horizon:

“One-click gear production”—that’s the vision.

Autonomous machining cells represent the next frontier in gear manufacturing. These integrated systems will combine:

Once a work order is fed into the system, the cell will handle everything—from raw material to finished, inspected gears—without operator intervention. This model is particularly attractive for:

Already, companies like FFG, Liebherr, and Gleason are developing modular automation kits for hobbing cells. In India, pilot lines in Pune and Chennai are experimenting with such configurations for Tier-1 suppliers.

From smart machines to smart factories—and now, smart networks.

Cloud connectivity is transforming how gear manufacturers manage operations. By aggregating and analysing machine data across multiple plants and geographies, manufacturers can:

Cloud-based analytics platforms—such as Siemens Mindsphere, Bosch Nexeed, and Rockwell FactoryTalk—are gaining traction in India. These systems offer dashboards that combine machine KPIs with business insights, allowing plant heads to make data-informed decisions across locations.

This is especially beneficial for:

AI won’t just optimize how we cut gears—it will reshape how we design them.

Traditionally, gear designs are handed off from engineering to production, often leading to back-and-forth adjustments when manufacturability issues arise. But with the rise of AI-powered DfM systems, this handoff will become a collaborative feedback loop.

How it works:

This tight integration between design, process planning, and execution will shorten development cycles and reduce design-induced inefficiencies. It also enables mass customisation, where different gear profiles can be produced on the same machine with minimal downtime.

Smart hobbing isn’t just good for productivity—it’s good for the planet.

With increasing pressure to meet Environmental, Social, and Governance (ESG) goals, manufacturers are seeking ways to track and improve their sustainability performance. Next-gen hobbing machines will be equipped with real-time environmental monitoring features, such as:

These metrics will feed into sustainability dashboards, allowing companies to:

Manufacturers that adopt these technologies early will not only reduce operational costs but also gain a competitive edge in securing international contracts—particularly in automotive and aerospace, where ESG compliance is becoming a selection criterion.

Furthermore, digital twin models can simulate the environmental impact of different production strategies, allowing gear manufacturers to choose the most sustainable (and cost-effective) path forward.

The transformation of hobbing machines from mechanical workhorses to intelligent manufacturing systems is more than a technological upgrade—it’s a strategic imperative. As global demand for high-precision gears rises and tolerance for errors drops, manufacturers that adopt AI-enabled, data-driven hobbing technologies will be the ones to lead.

For India, the challenge is two-fold: modernise legacy systems and scale up smart manufacturing capabilities to match global benchmarks. The good news is that the building blocks are already in place—talent, innovation, and ambition.The future of gear hobbing isn’t just about cutting teeth—it’s about cutting-edge thinking.