ABB Robotics is expanding its extensive range of large robots by introducing four new models and 22 variations. This expansion aims to provide customers with more options, broader coverage, and enhanced performance. The latest generation includes the IRB 6710, IRB 6720, IRB 6730, and IRB 6740, designed for payloads ranging from 150kg to 310kg, with a reach spanning 2.5m to 3.2m. This offering not only increases customer choices but also delivers significant improvements in performance and energy efficiency.

Marc Segura, the President of ABB’s Robotics Division, emphasized the importance of sustainable production in the automotive industry, citing that 78 percent of companies consider it crucial for their business, with 77 percent identifying it as a priority for their customers. The four new robots, with 22 variants, address these concerns by providing up to 20 percent energy savings and offering greater flexibility for sustainable production across various industries such as automotive, general manufacturing, foundry, food and beverage, and logistics.

The energy efficiency enhancements are attributed to ABB’s OmniCore controller and a lighter robot design, resulting in up to 20 percent energy savings. OmniCore also ensures high motion control accuracy. The robots, equipped with ABB’s TrueMove and QuickMove motion control technology, achieve class-leading repeatability with a deviation as minimal as 0.03mm. These features make the new robot series well-suited for intricate tasks like spot welding, laser welding, screwdriving, and riveting, enabling automotive manufacturers to achieve high-quality assembly.

Joerg Reger, the Managing Director of ABB Robotics Automotive Business Line, highlighted the relevance of the new robot range for the growing electric vehicle (EV) industry. As EV and battery production expands, manufacturers can choose from ABB’s diverse robot options to handle batteries of varying sizes, perform high-precision car body assembly, spot welding, and navigate restricted areas within a vehicle for tasks like installing seats or dashboards.

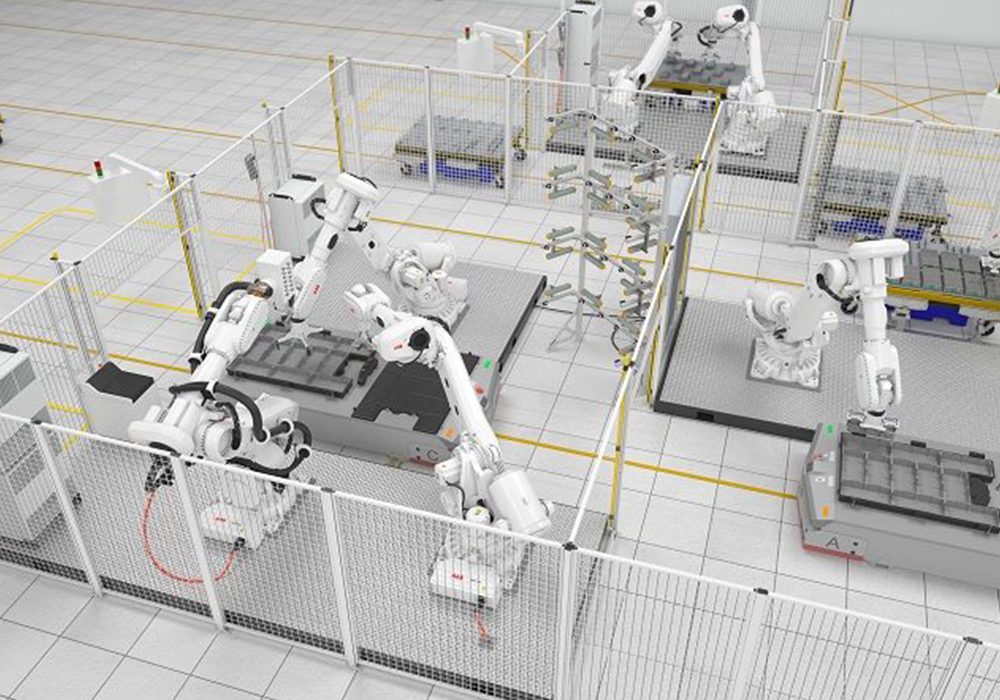

These new large robots will be showcased at ABB’s stand during Automatica 2023 (Hall B5, Booth 319, June 27th – 30th), demonstrating their capabilities in a fully functional battery production cell. The robots will be engaged in spot welding tasks, loading and unloading EV-battery tray parts, facilitated by one of ABB’s fully autonomous mobile robots.