By Sushmita Das

In the world of gear production, one of the most critical processes that significantly impact performance and quality is heat treatment. This transformative procedure takes raw materials and subjects them to controlled heating and cooling, altering their molecular structure to unlock their full potential. In this article, we will delve into the fascinating world of heat treatment and explore how it revolutionizes raw materials for gear production, paving the way for exceptional gear performance.

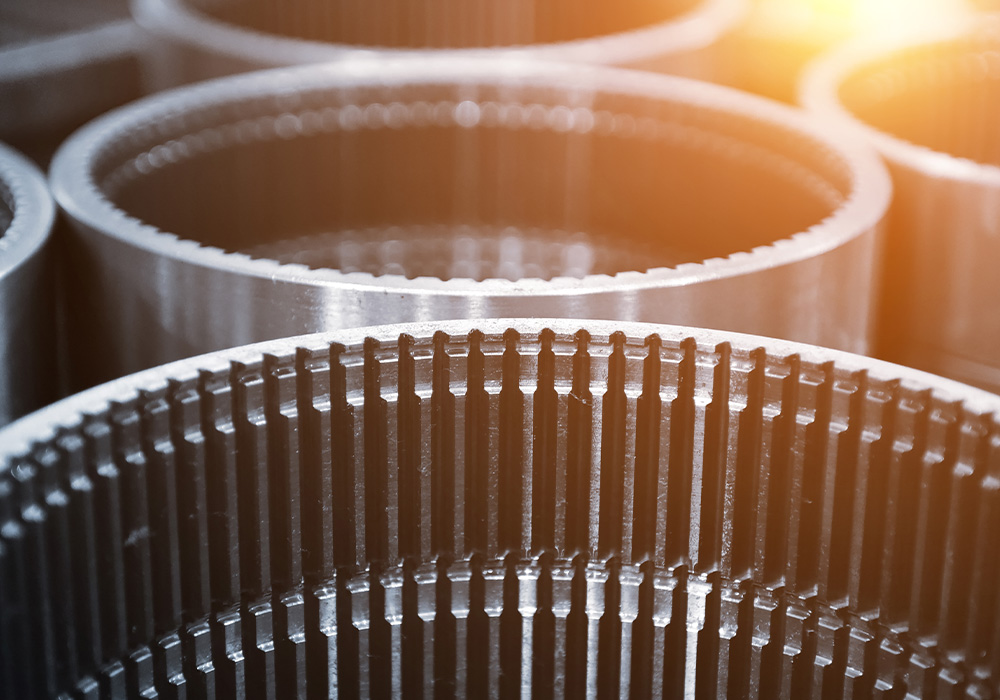

Gears are the backbone of many mechanical systems, transmitting power and enabling precise motion. The ability to withstand heavy loads, resist wear, and maintain optimal performance is paramount. This is where heat treatment plays a pivotal role. By carefully manipulating the material’s properties, heat treatment enhances strength, hardness, toughness, and wear resistance – all vital attributes for superior gears.

The process begins with the careful selection of raw materials, predominantly steel, considering factors such as the desired gear hardness and mechanical properties. Different grades of steel possess unique characteristics, and the appropriate choice is critical to achieving the desired gear performance.

Once the raw material is selected, it undergoes a series of heat treatment steps. The first step is known as austenitizing. During this stage, the material is heated to a specific temperature, usually above its transformation point. This temperature allows the steel to form an austenitic structure, which is essential for subsequent heat treatment processes.

The next critical phase is quenching. In this step, the heated material is rapidly cooled, typically through immersion in a quenching medium like oil, water, or polymer. Quenching transforms the austenite into a hardened structure, significantly improving the material’s strength and hardness. To avoid distortion, cracking, or excessive brittleness, precise control of the cooling rate and quenching medium selection is imperative.

Following quenching, the gears enter the tempering stage. This process involves reheating the hardened steel to a specific temperature below the critical range, followed by controlled cooling. Tempering relieves internal stresses, enhances toughness, and optimizes the balance between hardness and ductility. The precise control of tempering temperature and time is crucial to achieving the desired gear properties.

It is important to note that heat treatment is a highly customized process, with parameters and sequences varying based on gear size, shape, intended application, and material composition. To meet specific requirements, manufacturers develop specialized heat treatment processes that maximize gear performance and durability.

To ensure the effectiveness of heat treatment, rigorous quality control measures are implemented. Non-destructive testing methods, such as hardness testing and magnetic particle inspection, help identify any defects or irregularities that may have occurred during the heat treatment process. Additionally, post-heat treatment machining and finishing processes contribute to achieving the desired gear dimensions and surface integrity.

Heat treatment is a powerful tool that unlocks the potential of raw materials in gear production. By subjecting steel to precise heating and cooling processes, manufacturers can optimize the material’s mechanical properties, resulting in gears that surpass expectations. This transformative process significantly improves gear performance, durability, and resistance to wear. With meticulous attention to material selection, precise control of heat treatment parameters, and robust quality control measures, manufacturers unlock the full potential of raw materials, leading to exceptional gear performance.

Therefore, heat treatment revolutionizes raw materials for gear production, enhancing their properties to meet the demands of mechanical systems. By manipulating the molecular structure through controlled heating and cooling, heat treatment unlocks the true potential of raw materials, ensuring gears that can withstand heavy loads, resist wear, and deliver optimal performance. This transformative process is the key to unlocking the power of gears and driving innovation in the field of mechanical engineering.