CNCtize PCD Runout Isometric view Redner

By: Sudhanva Shevade

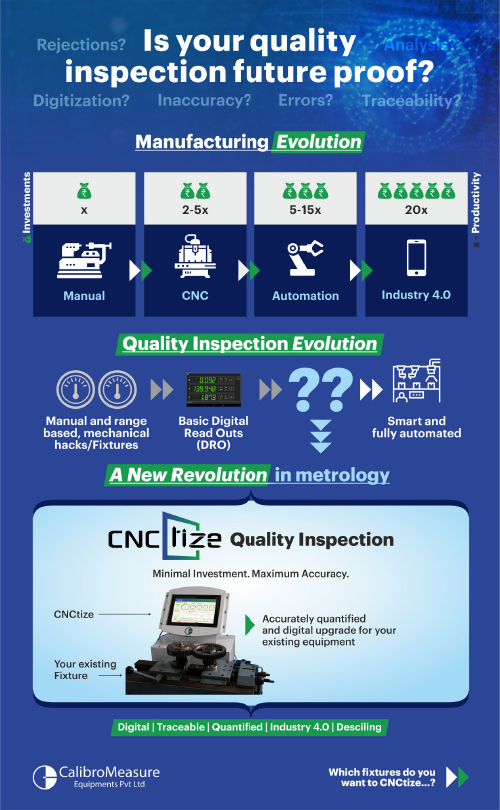

In recent years, the costs associated with gear quality inspections have been on the rise. Several key factors have contributed to this upward trend.

First, the growing complexity of gear designs necessitates more intricate inspection processes and specialized equipment.

Two, stricter industry regulations and customer demands for higher quality standards require additional testing and documentation, and finally the need for skilled personnel to perform these inspections further drives up costs.

It is crucial for manufacturers to address these challenges and ensure cost-effective quality control without compromising on the integrity and reliability of their gear products. But how can this be achieved? We look at a few ways.

The existing quality inspection equipment such as dial gauge-based Manual Gear Roll Tester, DoB or DuB fixtures, or PCD Runout measurement with DROs is primarily attribute-based (DRO is quantified, but human judgment dependent).

Such inspection is prone to errors, provides limited insights into the process and is operator dependent, but without much scope for traceability.

While analog measurement systems have served us well, they do have limitations in terms of accuracy, efficiency, and data analysis capabilities.

The future of gear quality inspection lies in quantified, digital solutions that leverage advanced technologies, AI-driven algorithms, and real-time data analytics.These systems must offer precision, faster throughput, and comprehensive insights for process optimization.

By transitioning to new measurement systems, manufacturers can unlock new levels of quality control, enhance productivity, and meet the ever-increasing demands of the industry. It’s time to embrace the new era and revolutionize gear quality inspection. The answer lies in embracing the transformative power of CNCtizing quality inspection.

Measuring higher precision with accuracy: Gears are critical components in many mechanical systems, and their performance depends on their precise dimensions and geometries.

Ensuring accurate and precise gear quality inspection requires advanced measuring techniques, such as coordinate measuring machines (CMMs), optical measurement systems, and 3D scanning, which can be challenging to implement and operate correctly.

Reliable quality inspection for complex geometries: Modern gears come in a wide variety of shapes, sizes, and geometries, including spur gears, internal gears, smaller-sized gears, and more. Inspecting these complex geometries for dimensional accuracy, tooth profile, and surface finish can be challenging, as it may require specialized measurement tools and software algorithms to interpret and analyze the data.

Super surface finish inspections: The surface finish of gears is critical for their performance, as it affects factors such as wear, noise, and efficiency.

However, accurate and reliable measuring surface finish can be challenging due to factors such as roughness, waviness, and the complex geometries of gears. Ensuring consistent and reliable surface finish inspection requires specialized equipment, and techniques.

In-process quality inspection in high-speed and large-scale production: Gears are used in various industries including automotive, aerospace, and heavy machinery where high-speed and large-scale production is common.

Conducting gear quality inspection in such production environments can be challenging due to factors such as high throughput rates, automation requirements, and the need for real-time inspection data. Developing and implementing inspection methods that can keep up with the high-speed production pace while maintaining accuracy and repeatability is a challenge.

Data-driven decisions, analysis and interpretation: Modern gear quality inspection generates a large amount of data, including dimensional measurements, surface finish data, and other parameters.Analyzing and interpreting this data can be challenging as it requires advanced data analysis techniques, statistical process control, and data management systems. Extracting meaningful insights from the data and making informed decisions based on it is a key challenge in gear quality inspection.

Eliminating human error and variability: Even with advanced measurement equipment, human error and variability can still be a challenge in gear quality inspection. Factors such as operator skill level, fatigue, and judgment can affect the accuracy and repeatability of gear inspections.

Ensuring proper training, standardization of inspection processes, and implementing robust quality management systems are essential to mitigate human error and variability in gear quality inspection.

Meeting compliance with standards and regulations: Gears are often subject to industry standards and regulations such as ISO, AGMA, and DIN standards, which define the tolerances, specifications, and inspection methods for gears. Ensuring compliance with these standards and regulations can be challenging, as they may be updated or revised periodically, and keeping up with the changes requires continuous monitoring and training of inspection personnel.

When it comes to gear quality inspection equipment, manufacturers are stuck with three choices.

First, continue as is as long as possible with the limitations of existing equipment.

This means arresting the scope for improving quality control which can be detrimental to overall growth of the company.

Second, upgrade existing equipment for digital output. The advantage here is that the existing equipment can be utilized to improve the accuracy of measurement. While this option helps to quantify the measurements, it leaves a wide gap when it comes to traceability, reducing operator dependency and process analysis.

The third option is to scrap the existing equipment and buy a new one with all the digital frills. This means provisioning for heavy investments, training and risks in case the advanced equipment doesn’t suit the process. Plus, it means longer lead time and added complexity on the shop-floor.

The fourth way is to go the CNCtize way.CNCtize is a revolutionary new way to advance your existing quality inspection equipment without significant investments. CNCtize gadget can be fitted on any of your existing fixtures. The gadget includes an LVDT Probe which attaches to the existing equipment.

CNCtize is powered by patented CMGM (Continuous Monitoring and Guide Module) and Artificial Intelligence Software. The gadget when attached to the fixture provides digital, quantified output while giving ok/not-ok decisions and providing complete traceability for the Operator and the process parameters.

As gear manufacturing continues to advance, gear quality inspection has become a crucial step in ensuring that gears meet the highest standards of accuracy, durability, and performance. India has emerged as one of the leading global manufacturers of gears, and gear exports from India have been on the rise in recent years.

CNCtize is helping progressive gear manufacturers to up their quality control game, and improve several benchmarks at once. For gear manufacturers, CNCtize is the one solution that helps to overcome several challenges by transforming their existing quality inspection fixtures to the most advanced levels at a fraction of the investments.

CNCtize is an innovation by CalibroMeasure Equipment Pvt. Ltd. – a specialized new-age solution provider in dimensional quality inspection for gears and transmission components. CalibroMeasure has several disruptive innovations in automating gear quality inspection including auto gear rolling.

DoB/DuB measurement, PCD runouts, as well as other critical parameters along with spline and shaft inspections.

Sudhanva Shevade, Director,

Marketing at CalibroMeasure Equipments Pvt. Ltd.

connect@calibromeasure.com

www.calibromeasure.in