By: Robert Ravensbergen

Machinery and gear manufacturers know the challenges of achieving high reliability at high volume while balancing it with frequent changeover. For that reason, automation solutions have sometimes been a mixed bag in adapting to the unique needs these manufacturers have in fabricating many different kinds of parts.

Why have automation solutions not kept pace? Well, fundamentally they are “deaf, dumb and blind”. These solutions rely almost entirely on manual programming and precise location jigging, which mean that changing their function is a time and labor-intensive process which involves significant incremental costs for each part added.

Autonomous robots built for value-added processes can change this, enabling manufacturers to overcome key bottlenecks – even in high-mix scenarios – by using process know-how in order to adapt to different parts, positions and orientations in real-process time.

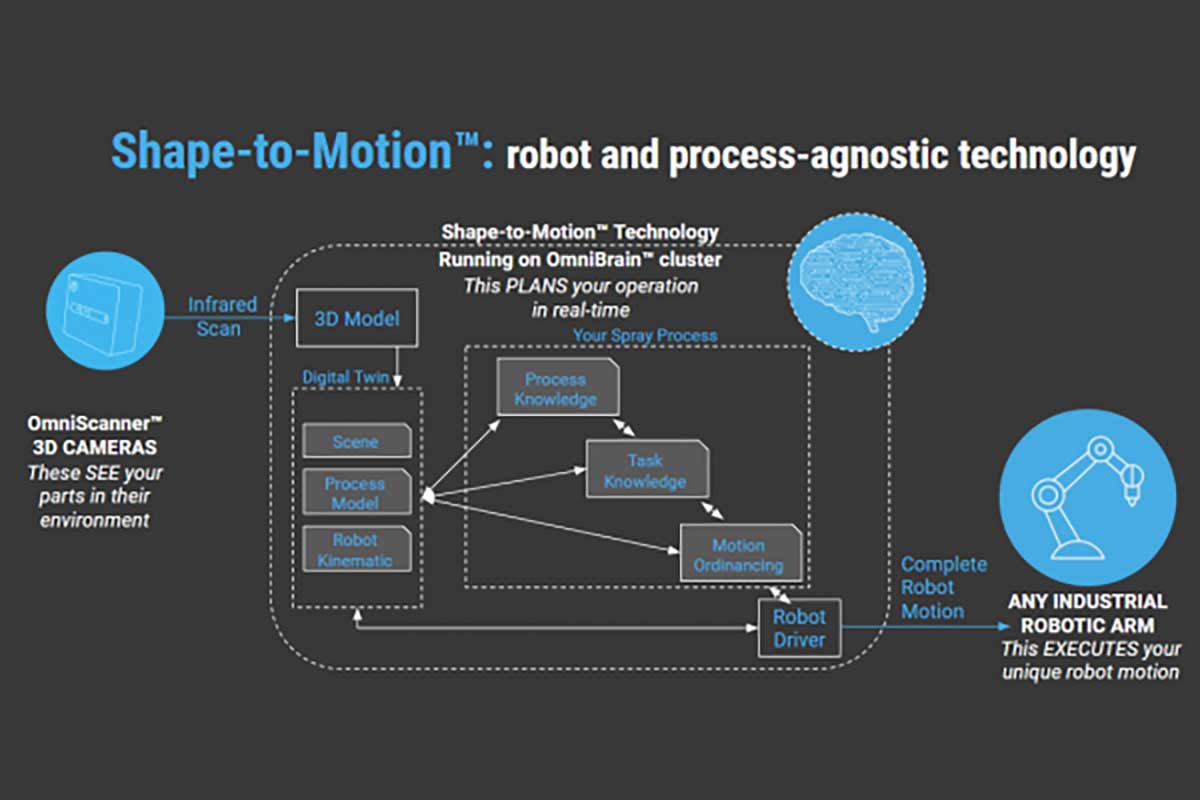

How can this be accomplished? Through a mix of AI-based task planning and automated robot motion program. At Omnirobotic, we’ve built Shape-to-Motion™ Technology to provide autonomous robotics for spray processes. This level of autonomy finally allows high-mix manufacturers to benefit from robotic consistency, productivity and reliability while eliminating bottlenecks and skills shortages on the factory floor. Fundamentally, it also reduces rework, downtime and materials and energy waste.

In the diagram below, you can see a basic outline of how this technology interprets parts and decides how to process them. By using 3D models of parts in their real environment, interpreted based on shape libraries, process constraints and a series of primitive segmented tasks, the technology is able to string together one unique, efficient robot motion for each part processed based only on simple instructions from the manufacturer. While the technology is currently available for spray processes, it is fundamentally designed to be “process-agnostic”, meaning that eventually applications can and will be built for welding, machining and more.

Rising labor costs and diminishing skilled labor supply has for a long time been impacting high-mix manufacturers more than any other sector. While the pandemic, social distancing and global uncertainty has created even more stress on many businesses, it’s important to know that autonomous robots can do more than simply carry objects from point A to point B. For once, help is on the way!

Robert Ravensbergen is the Marketing Director at Omnirobotic, the only provider of autonomous robotics technology for industrial spray processes. You can reach omnirobotic at sales@omnirobotic.com or visit https://omnirobotic.com/.